Asphalt modifier and preparation method thereof

A technology of asphalt modifier and surfactant, applied in the field of asphalt modifier and its preparation, can solve the problems of difficult treatment, pollute the environment, occupy land resources, etc., achieve broad application prospects, improve comprehensive performance, and improve high temperature stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 Preparation of asphalt modifier of the present invention

[0032] Take 100.0g of mixed silane (mixed silane is a liquid-solid mixture with fluidity obtained by wet dust removal during the synthesis of methylchlorosilane monomer, the same below), surfactant Tween-402.0g, granular 900.0g of tire rubber powder with a diameter of 10 to 80 meshes, mix, stir and heat to 130-220°C, then maintain 130-220°C to react for 20-30 minutes, cool down and discharge the material to obtain an asphalt modifier.

Embodiment 2

[0033] Example 2 Preparation of asphalt modifier of the present invention

[0034] Take 300.0g of mixed silane, 4.0g of surfactant Tween-60, and 700.0g of tire rubber powder with a particle size of 10-80 mesh, mix, stir and heat to 130-220℃, and then maintain 130-220℃ for reaction 20-30min, cooling and discharging to obtain asphalt modifier.

Embodiment 3

[0035] Example 3 Preparation of asphalt modifier of the present invention

[0036] Take 500.0g of mixed silane, 5.0g of surfactant Tween-65, and 500.0g of tire rubber powder with a particle size of 10 to 80 mesh, mix well, stir and heat to 130-220℃, and then maintain 130-220℃ for reaction 20-30min, cooling and discharging to obtain asphalt modifier.

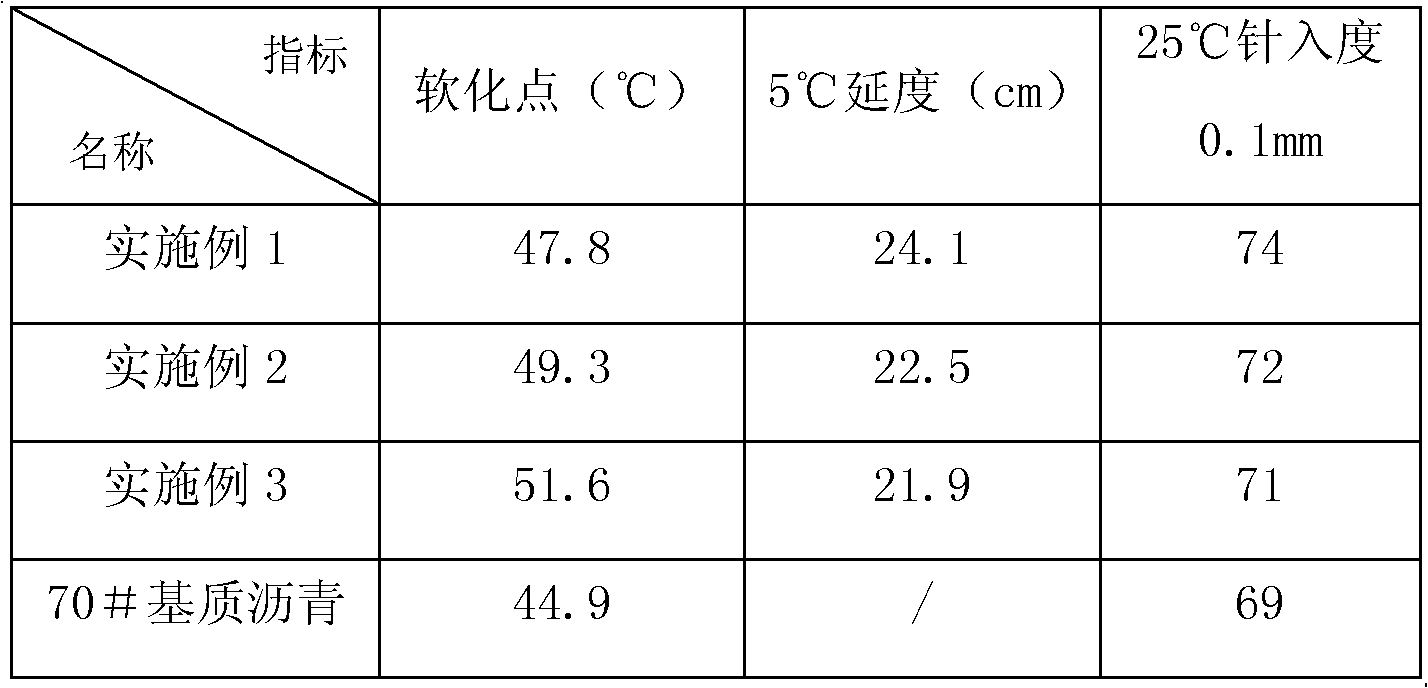

[0037] The asphalt modifiers prepared in Examples 1-3 were added to 70# base asphalt at 2wt% respectively, mixed well, and then heated to 180°C, stirred at a speed of 500r / min and continued to react for 30min; when the temperature was cooled to 150°C , Transfer the material to a colloid mill, grind for 10 minutes, cool down and discharge the material to obtain an asphalt product modified with the modifier of the present invention, and measure its performance. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com