Method for recovering heavy metal in electrolytic manganese passivating wastewater

A technology of electrolytic manganese and heavy metals, applied in chemical instruments and methods, metallurgical wastewater treatment, water/sewage treatment, etc., can solve the problems of waste of useful resources, polluting solid waste, etc., and achieve low production costs, continuous operation, Ease of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The invention discloses a method for recovering heavy metals in electrolytic manganese passivation wastewater, wherein the electrolytic manganese passivation wastewater is electrolytic manganese passivation wastewater containing divalent manganese ions and hexavalent chromium ions. Processing method of the present invention comprises the following steps:

[0014] (1) Add alkali to the electrolytic manganese passivation wastewater to adjust its pH value to 8-12;

[0015] (2) Add soluble carbonate to the electrolytic manganese passivation wastewater that has adjusted the pH value, and stir for 60 to 120 minutes at normal temperature; wherein, the carbonate ion in the soluble carbonate and the electrolytic manganese passivation wastewater The mol ratio of divalent manganese ion is 1.2: 1; Obtain the mixed solution containing manganese carbonate; The chemical equation of this step is: Mn 2+ +CO 3 2- =MnCO 3 ↓

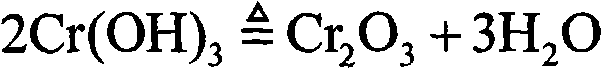

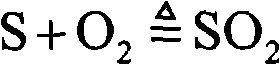

[0016] (3) In the mixed solution containing manganese carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com