Smelting process of recycling chromium by combined-injection dephosphorizing using stainless steel precipitator dust

A stainless steel and dephosphorization technology, applied in the field of smelting, can solve the problems such as the inability to effectively recover metal chromium and environmental pollution, and achieve the effect of reducing production costs and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The technical solutions and beneficial effects of the present invention will be described in further detail below.

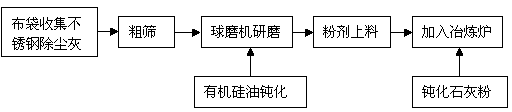

[0052] A smelting process for recovering chromium by composite spraying and dephosphorization of stainless steel dust ash, which is characterized in that it includes the following steps:

[0053] Step 1. Passivation of stainless steel dust ash: the collected stainless steel dust ash is coarsely screened, and the moisture-absorbing and agglomerated particles are sealed and ground in a ball mill. The temperature in the ball mill is 80-100 ℃, which is added during the grinding process Silicone oil, the amount of silicone oil added is 1-15% of the total weight of the passivation powder to form an oil film on the surface of the stainless steel dust ash particles, and the particle size of the stainless steel dust ash after grinding is less than 100 μm;

[0054] Step 2: Loading: the passivated stainless steel dust removal ash prepared in step 1 is loaded into the powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com