Baking-free lightweight insulating brick and preparation method thereof

A light-weight technology for insulating bricks, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of limited product application range, large capacity of insulating bricks, poor economic benefits, etc., and achieve obvious economic benefits And popularize the effect of using value, good thermal insulation performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

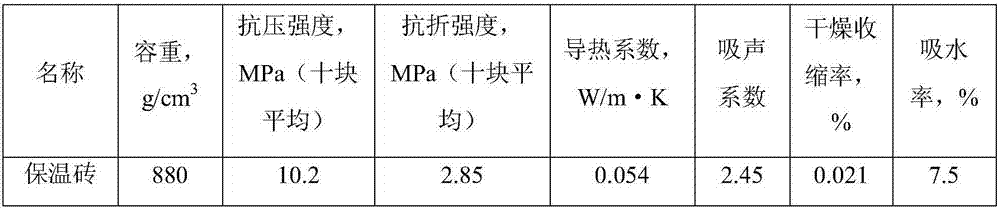

Embodiment 1

[0024] A non-fired lightweight insulating brick, which comprises 65% of mineral wool waste (including 35% of slag balls and 30% of slag wool fibers), 15% of slag portland cement, and 14% of powder Coal ash, 6% water. The mineral wool waste is crushed, the average fiber length is 14mm, and the particle size of the slag ball is 3mm. The cement is grade 32.5 slag portland cement. The fly ash raw material is subjected to impurity removal process, and the particle size is 100 μm.

[0025] The preparation method of the thermal insulation brick includes batching, stirring, billet making, and maintenance procedures, specifically including: 1) batching, preparing slag wool waste, cement, fly ash, and water in proportion; 2) stirring, first putting the slag wool waste and cement , fly ash, and then add water in proportion to stir for 14 minutes to obtain a mixture; 3) blank making, the mixture is vibrated to obtain a brick;

[0026] In the natural maintenance process, water is drawn ...

Embodiment 2

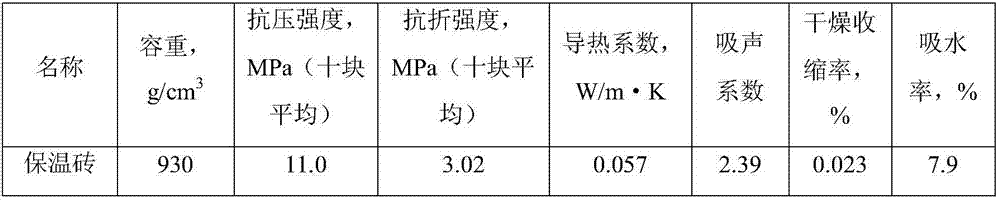

[0030] A non-fired lightweight insulating brick, which comprises 55% mineral wool waste (including 32% slag balls, 23% slag wool fibers), 15.5% slag Portland cement, 20% pulverized coal Ash, 9.5% water. The mineral wool waste is crushed, the average fiber length is 12 mm, and the particle size of the slag ball is 2.8 mm. The cement is grade 32.5 slag portland cement. The fly ash raw material has a particle size of 80 μm after an impurity removal process.

[0031] The preparation method of the thermal insulation brick includes batching, stirring, billet making, and maintenance procedures, specifically including: 1) batching, preparing slag wool waste, cement, fly ash, and water in proportion; 2) stirring, first putting the slag wool waste and Cement, fly ash, and then add water in proportion and stir for 15 minutes to obtain a mixture; 3) Blank making, the mixture is vibrated to obtain adobe; 4) Curing, the adobe is cured at room temperature to obtain an unfired lightweight t...

Embodiment 3

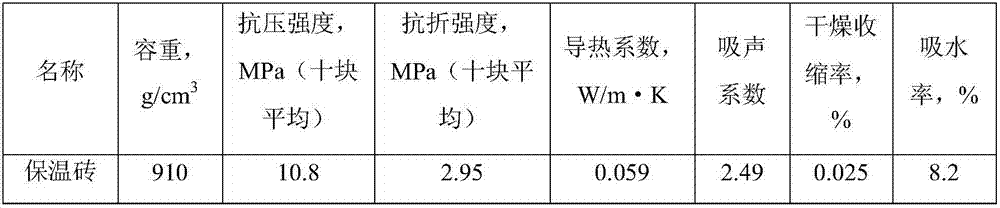

[0036] A non-fired lightweight insulating brick, which includes 59% mineral wool waste (including 34% slag balls, 25% rock wool fibers), 16.2% slag Portland cement, and 15% pulverized coal Ash, 9.8% water. The rock wool waste is crushed, the average fiber length is 11.5 mm, and the particle size of the slag ball is 2.6 mm. The cement is grade 32.5 slag portland cement. The fly ash raw material has been subjected to impurity removal process, and the particle size is 75 μm.

[0037] The preparation method of the thermal insulation brick includes batching, stirring, billet making, and maintenance procedures, specifically including: 1) batching, preparing rock wool waste, cement, fly ash, and water in proportion; 2) stirring, first putting rock wool waste and cement , fly ash, and then add water according to the proportion and stir for 18 minutes to obtain the mixture; 3) blank making, the mixture is vibrated to obtain adobe;

[0038] In the natural maintenance process, the fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com