Odor gas purification method and purification device

A technology for malodorous gas and purification device, which is applied in chemical instruments and methods, separation devices, separation methods, etc., can solve the problems of complex composition, inability to achieve emission standards, and high concentration, achieve good thermal insulation effect, save installation engineering, guarantee The effect of purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

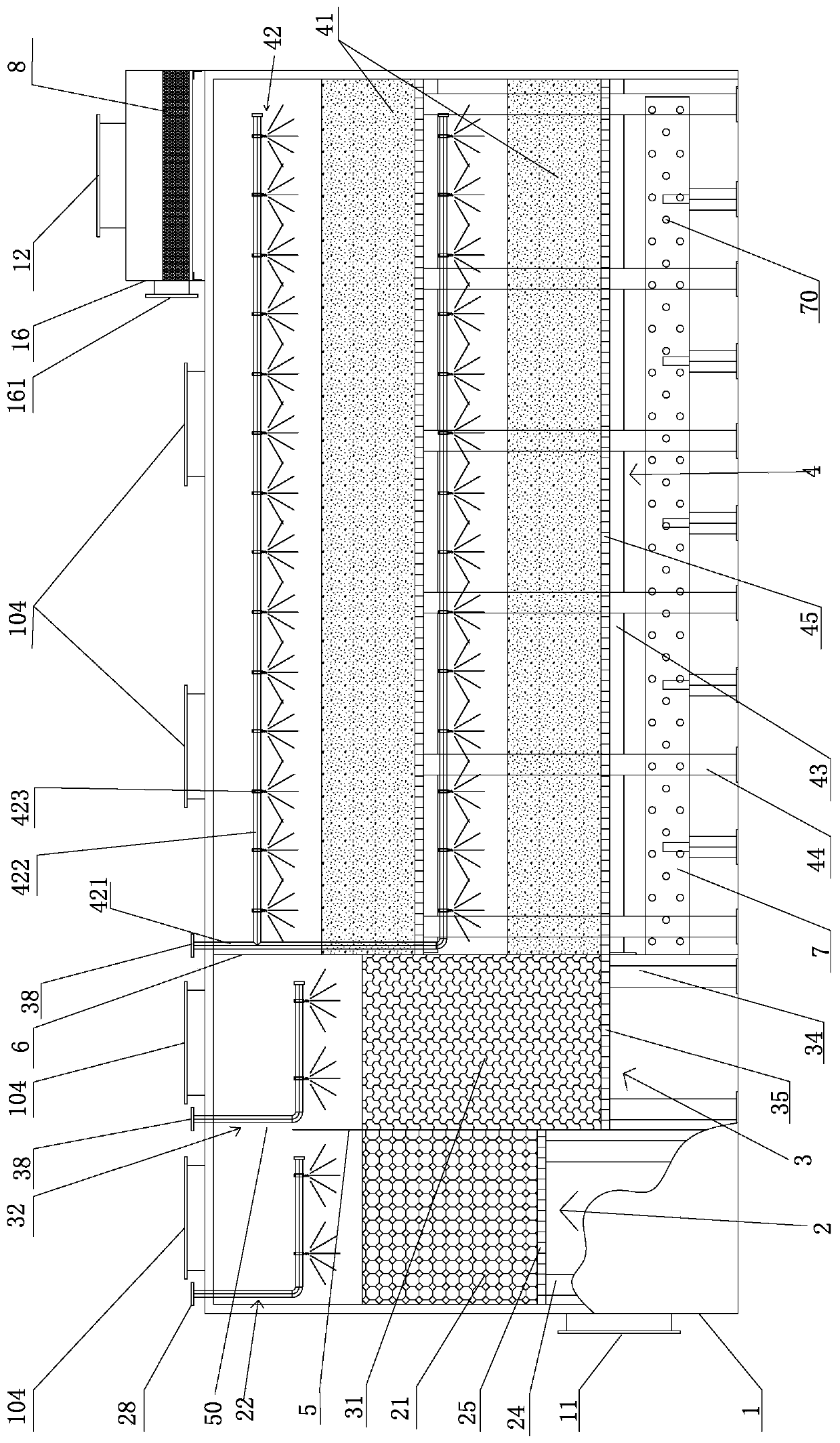

[0029] The invention discloses a method for purifying malodorous gas. The malodorous gas is subjected to biological oxidation treatment after cooling, dust removal, oxidation, neutralization and absorption treatment.

[0030] The malodorous gas contacts and reacts with the oxidizing spray liquid in the oxidizing packing layer, the malodorous gas is cooled, the dust in the malodorous gas is removed, the water-soluble components in the malodorous gas are dissolved in the oxidizing spray liquid, and the Hydrogen sulfide and reducing substances are removed by oxidation reaction with the oxidant in the oxidizing spray liquid; preferably, the malodorous gas after cooling, dust removal, and oxidation is contacted and reacted with the alkaline spray liquid in the humidifying and absorbing filler layer. , the acid, alcohol, and oil components of the malodorous gas undergo a neutralization reaction with the alkaline components in the alkaline spray liquid and are absorbed and removed.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com