Industrial production sewage treatment system

A sewage treatment system and water inlet technology, applied in water/sewage treatment, water/sewage treatment equipment, water/sewage multi-stage treatment, etc., can solve problems such as large pollution system, unable to meet technical and discharge index requirements, and achieve Reduce economic investment costs, reduce toxic and harmful and condensate, and improve the effect of safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The content of the present invention will be described below in conjunction with specific embodiments.

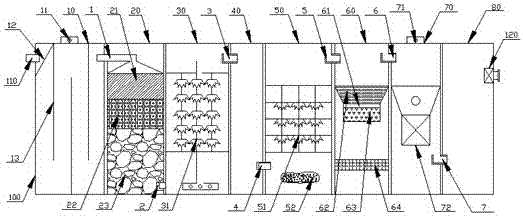

[0016] Such as figure 1 As shown, it is a schematic structural diagram of a sewage treatment system for industrial production according to the present invention, including: a housing 100, the two sides of the housing 100 are provided with a water inlet 110 and a water outlet 120, and sewage enters the housing from the water inlet 110 After 100, it passes through the baffle adjustment area 10, the multi-layer filtration system 20, the facultative anaerobic sedimentation area 30, the buffer zone 40, the aerobic area 50, the sedimentation area 60, the purification area 70, the water outlet pool 80, and finally from the water outlet 120 Outflow, the facultative anaerobic precipitation zone 30 is filled with facultative anaerobic sedimentation zone filler 31, the aerobic zone 50 is filled with aerobic zone filler 51 and the bottom is provided with a microdynamic aeration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com