Spinneret, oiling device, production device and production method for synthetic fibers

A technology for synthetic fibers and spinning heads, which is applied in the field of elastic fiber devices and synthetic fiber manufacturing, and can solve problems such as poor value and reduced appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

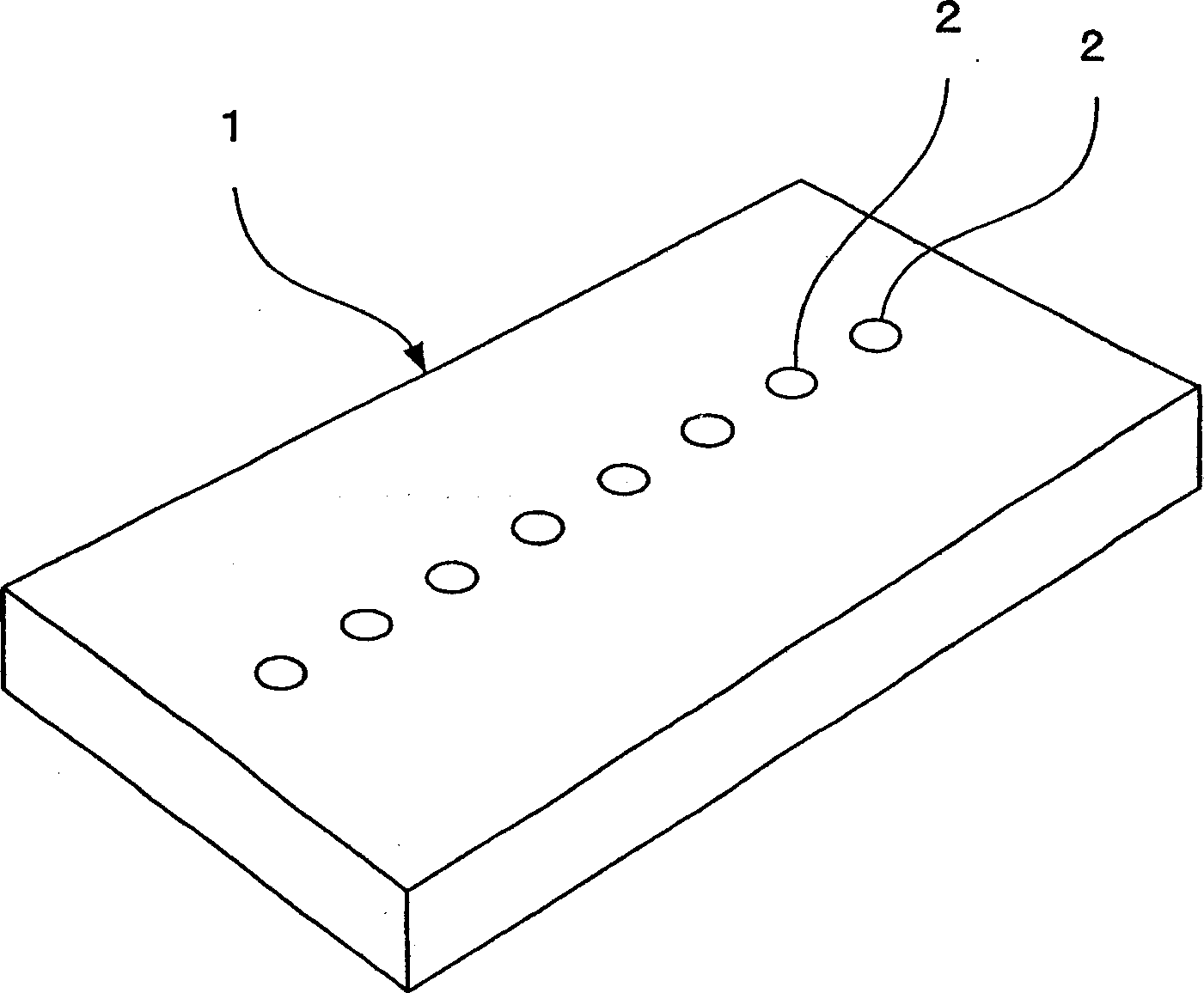

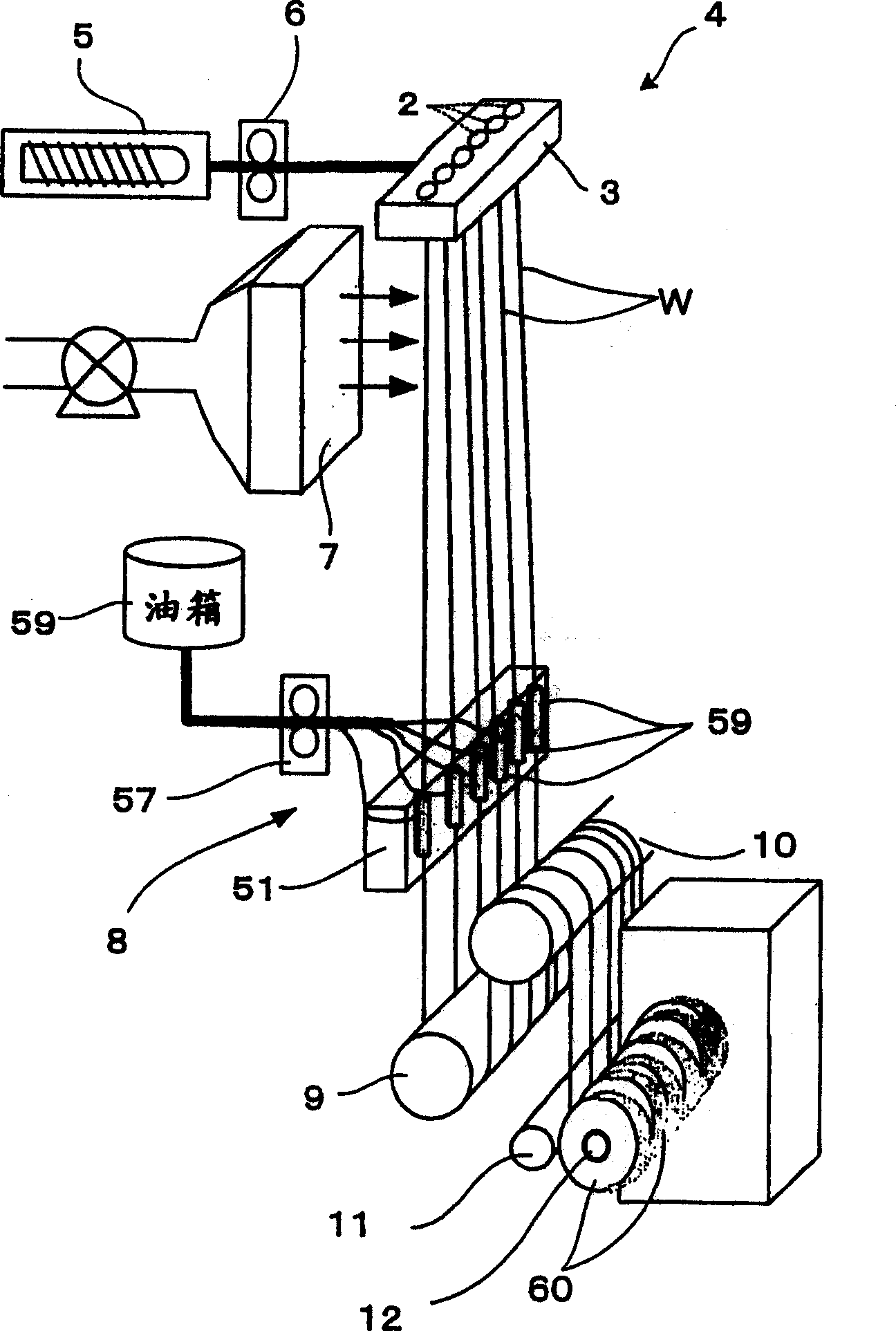

[0106] Thermoplastic polyurethane resin is melt-spun at a melting temperature of 220°C from a spinning machine having 24 holes (hole diameter φ1.0) formed in a line in a line (SUS630: W360×T80×H20mm) The head was spun and cooled by rectified unidirectional cooling air blown from perpendicular to the direction of the row at a velocity of 0.3 m / min. Then, the filament was oiled by roller oiling, and the formed molten spandex filament (22 dtex, one filament) was wound up. The vibration of the filaments during winding in the cooling zone, the properties of the obtained filaments, the unevenness of the filaments and the grade of the bare knitted fabric were evaluated.

example 2

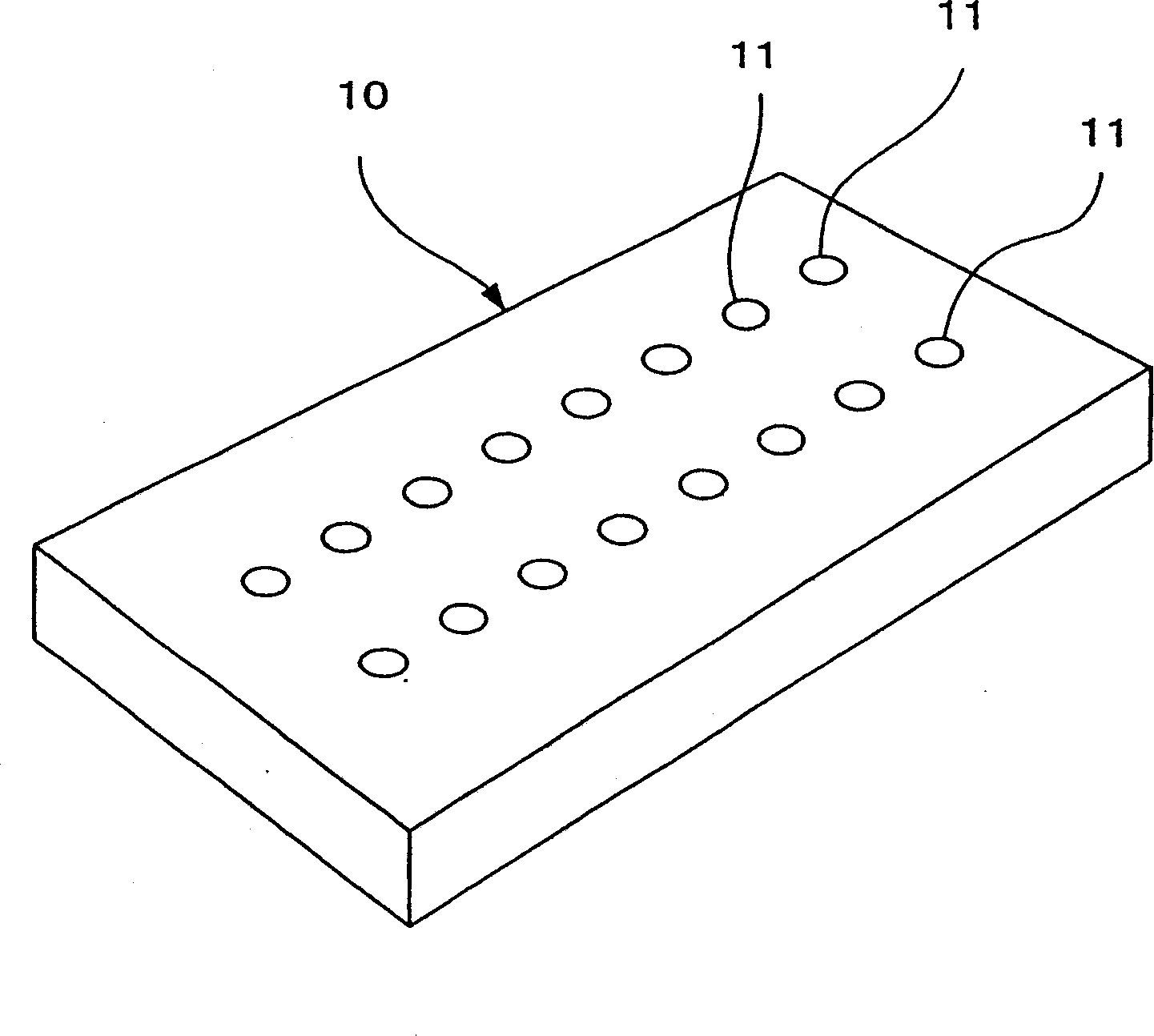

[0108] Thermoplastic polyurethane resin is melt-spun at a melting temperature of 220°C, from a spinning machine having 24 holes (hole diameter φ1.0) formed in a line in a line (SUS630: W360×T80×H20mm) The head was spun and cooled by rectified unidirectional cooling air blown from perpendicular to the direction of the row at a velocity of 0.3 m / min. Then, the filament was oiled by roller oiling, and the formed fused spandex filament (44 dtex, 2 filaments) was wound up. Perform an evaluation similar to Example 1.

example 3

[0110] Thermoplastic polyurethane resin is melt-spun at a melting temperature of 220°C from a spinning machine having 24 holes (hole diameter φ1.0) formed in a line in a line (SUS630: W360×T80×H20mm) The head was spun and cooled by rectified unidirectional cooling air blown from perpendicular to the direction of the row at a velocity of 0.3 m / min. Then, the filament was oiled by roller oiling, and the formed fused spandex filament (66 dtex, 3 filaments) was wound. Perform an evaluation similar to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com