Suspension type monorail track and trolley bus

A suspended, monorail technology, applied in the field of transportation, can solve the problems of increased energy consumption, damage to the running track surface, troublesome operation, etc., and achieve the effect of prolonging the replacement cycle, improving the wear resistance and improving the convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

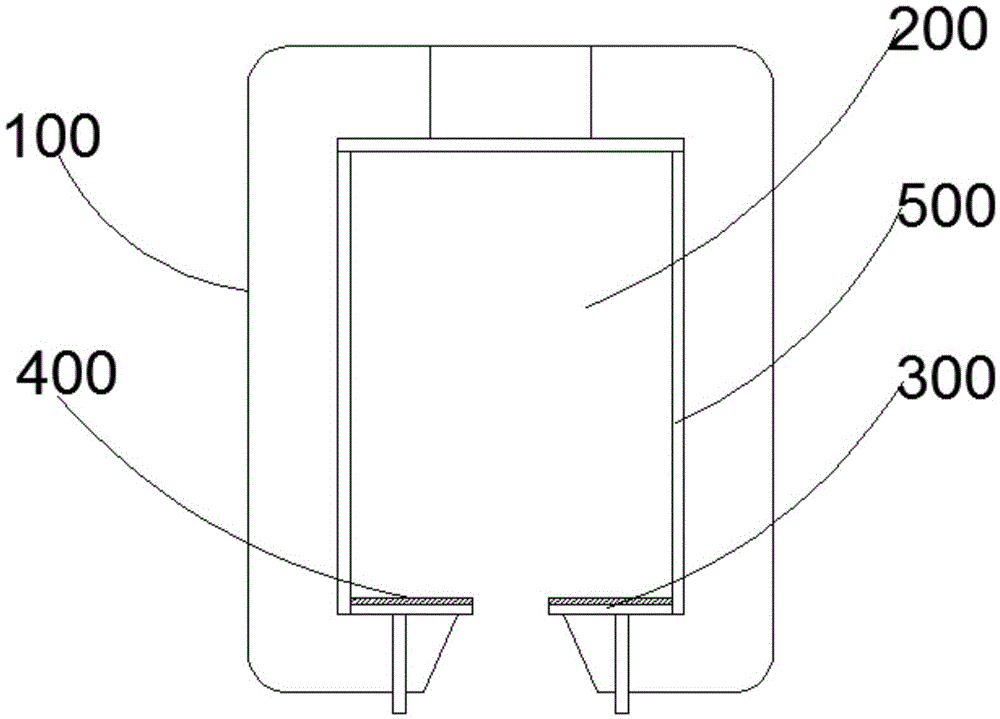

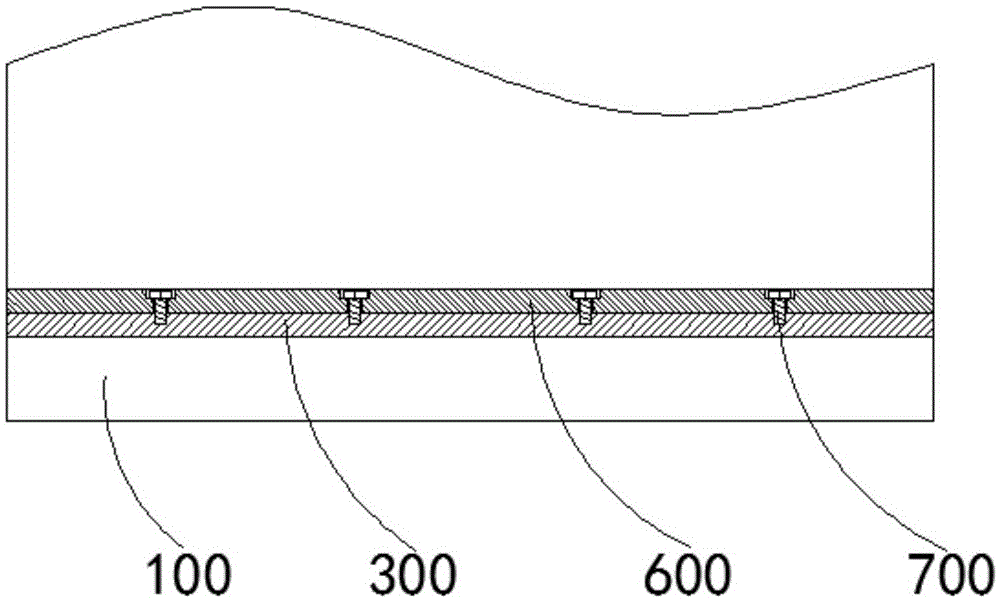

[0038] For the first embodiment, refer to figure 1 , The suspended monorail track includes a track beam 100, a running cavity 200 is arranged on the track beam 100, the bottom of the running cavity 200 is a running surface, and an anti-wear adhesion layer is arranged on the running surface.

[0039] Wherein, the track beam 100 includes an outer steel shell with an inverted U-shaped cross section and a plurality of inverted reinforcing ribs, the plurality of reinforcing ribs are evenly spaced along the length direction of the outer steel shell, and the outer steel shell is made of high-strength steel It is processed and formed to stably support the whole electric car. The reinforcing rib is an inverted U-shaped steel bar. The outer wall of the U-shaped steel bar is welded to the inner wall of the outer steel shell. Both ends) are respectively bent 90° inwards to form two running platforms for supporting the running wheels. The two running platforms and the side walls and top wa...

no. 2 example

[0057] The second embodiment, the device provided by the embodiment of the present invention, its implementation principle and technical effect are the same as the first embodiment, for brief description, for the parts not mentioned in the device embodiment, please refer to the corresponding content.

[0058] In this embodiment, a Teflon layer is provided on the upper surface of the rubber layer.

[0059] Among them, the Teflon is polytetrafluoroethylene, abbreviated as PTFE, commonly known as "Plastic King", which is a synthetic polymer material that uses fluorine to replace all hydrogen atoms in polyethylene.

[0060] The purpose of choosing Teflon is that it has excellent wear resistance and corrosion resistance, which is very suitable for high-load and severely corrosive working environments. Rolling friction, thereby reducing the resistance of the tram to travel.

no. 3 example

[0061] The third embodiment, the implementation principle and technical effect of the device provided by the embodiment of the present invention are the same as those of the first embodiment. For a brief description, for the parts not mentioned in the device embodiment, please refer to the corresponding content.

[0062] In this embodiment, the elastic material layer 400 is an adhesive layer.

[0063] Wherein, the viscose is viscose fiber, also called rayon and viscose filament, which belongs to regenerated cellulose fiber. It is made of natural cellulose as raw material, which is made into soluble cellulose sulfonate through alkalization, aging, sulfonation and other processes, and then dissolved in dilute lye to make viscose, which is made by wet spinning.

[0064] The purpose of selecting viscose is that it has the characteristics of low cost, good mechanical properties, and excellent fatigue resistance, which can effectively prolong the service life of the anti-wear adhes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com