Dynamic balance correcting method for fan

A correction method and fan technology, applied in the static/dynamic balance test, machine/structural component test, measuring device, etc., can solve the problems of enterprise loss, increase of production and operation cost, consumption of large manpower and material resources, etc., to reduce production The effect of reducing operating costs, prolonging the maintenance and replacement cycle, and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

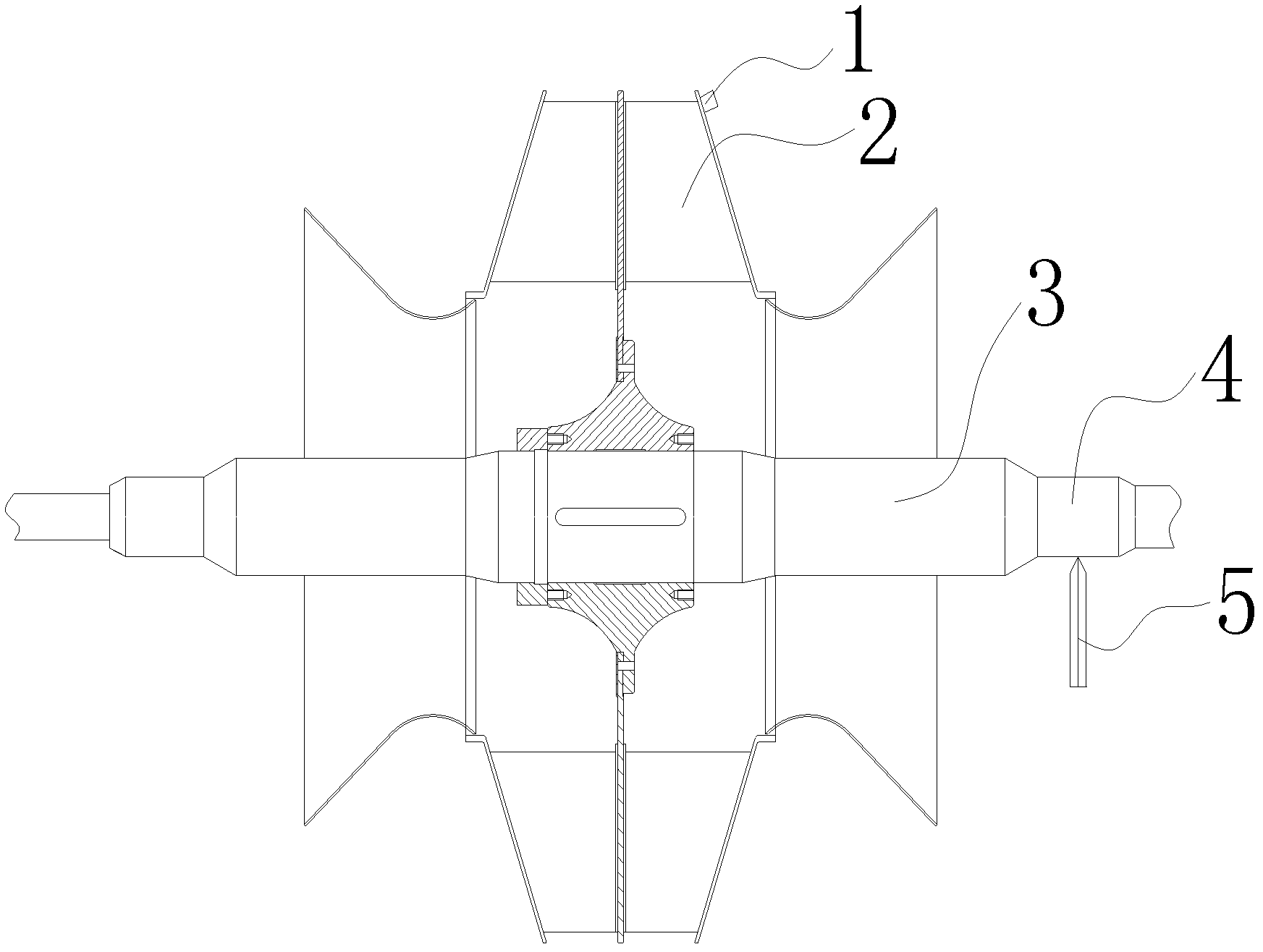

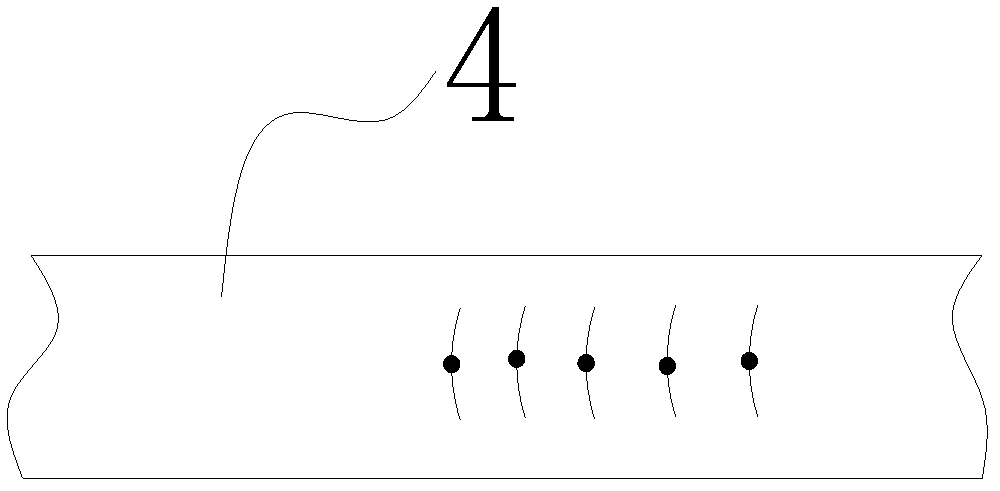

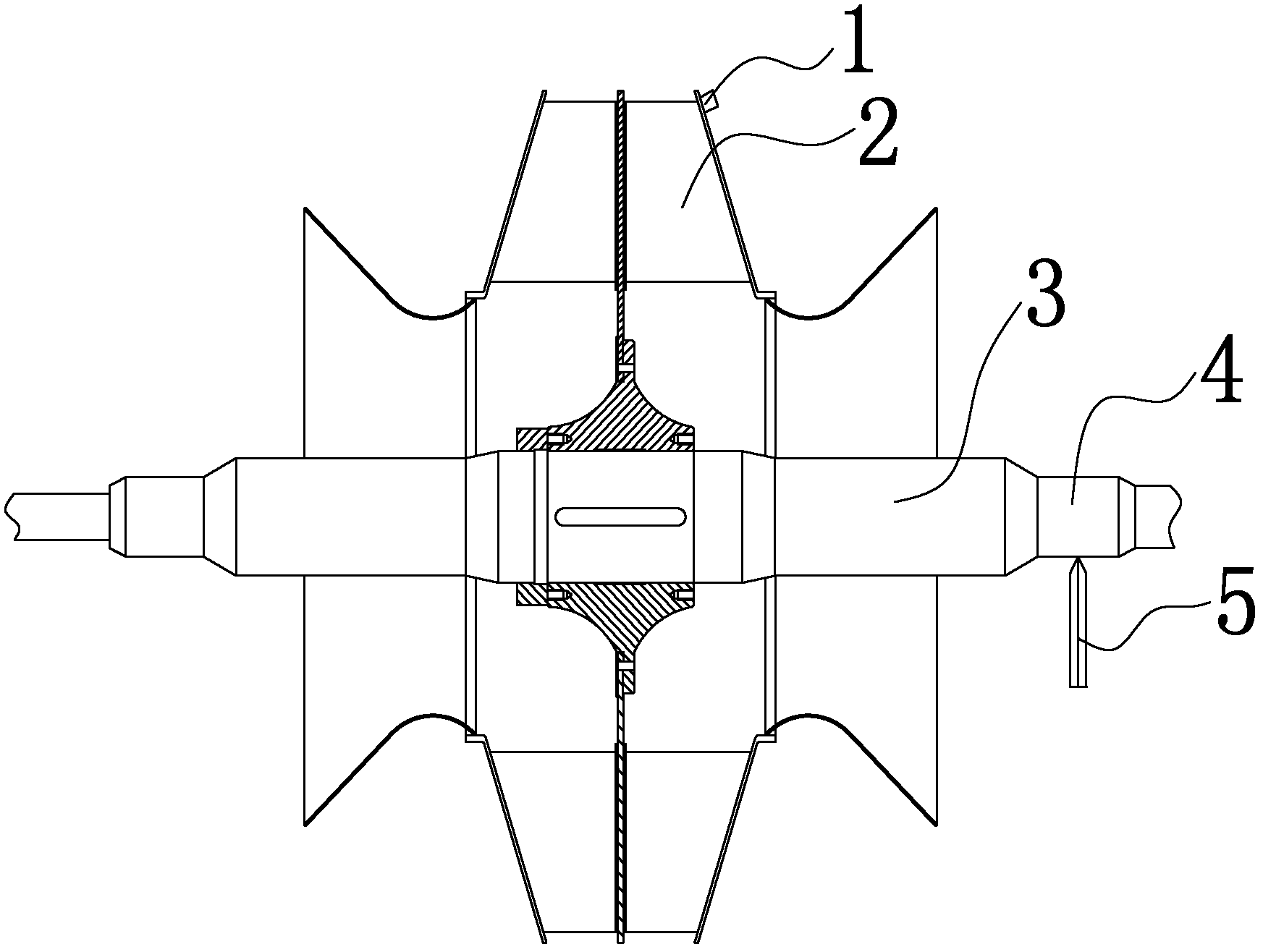

[0027] Specific embodiment: the quality M=10000kg of a blower fan impeller 2, the radius r=1200mm of impeller 2, the operating speed n=1000r / min of impeller 2, the balance grade is G6.3, the dynamic balance of this blower fan is destroyed, First, determine the unbalance point of the fan, and use the vibrometer to measure the radial vibration displacement of the fan due to unbalance △ = 0.10mm, and then calculate the allowable unbalance of the fan eper = (G×1000) / (n / 10)=(6.3×1000) / (1000 / 10)=63μm, the allowable residual unbalance of the fan m=(eper×M) / (r×2)=(63×10000) / (1200×2 )=262.5g, then calculate the unbalanced amount of the fan m″=(m / 0.13)×△=the unbalanced amount of the fan m″=(262.5 / 0.13)×0.10=201.9g, after calculating the unbalanced amount m″ of the fan, cut A counterweight 1 with a weight of 201.9g is fixed at the non-working position of the impeller 2 at an unbalanced point corresponding to an angle of 180° to balance the fan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com