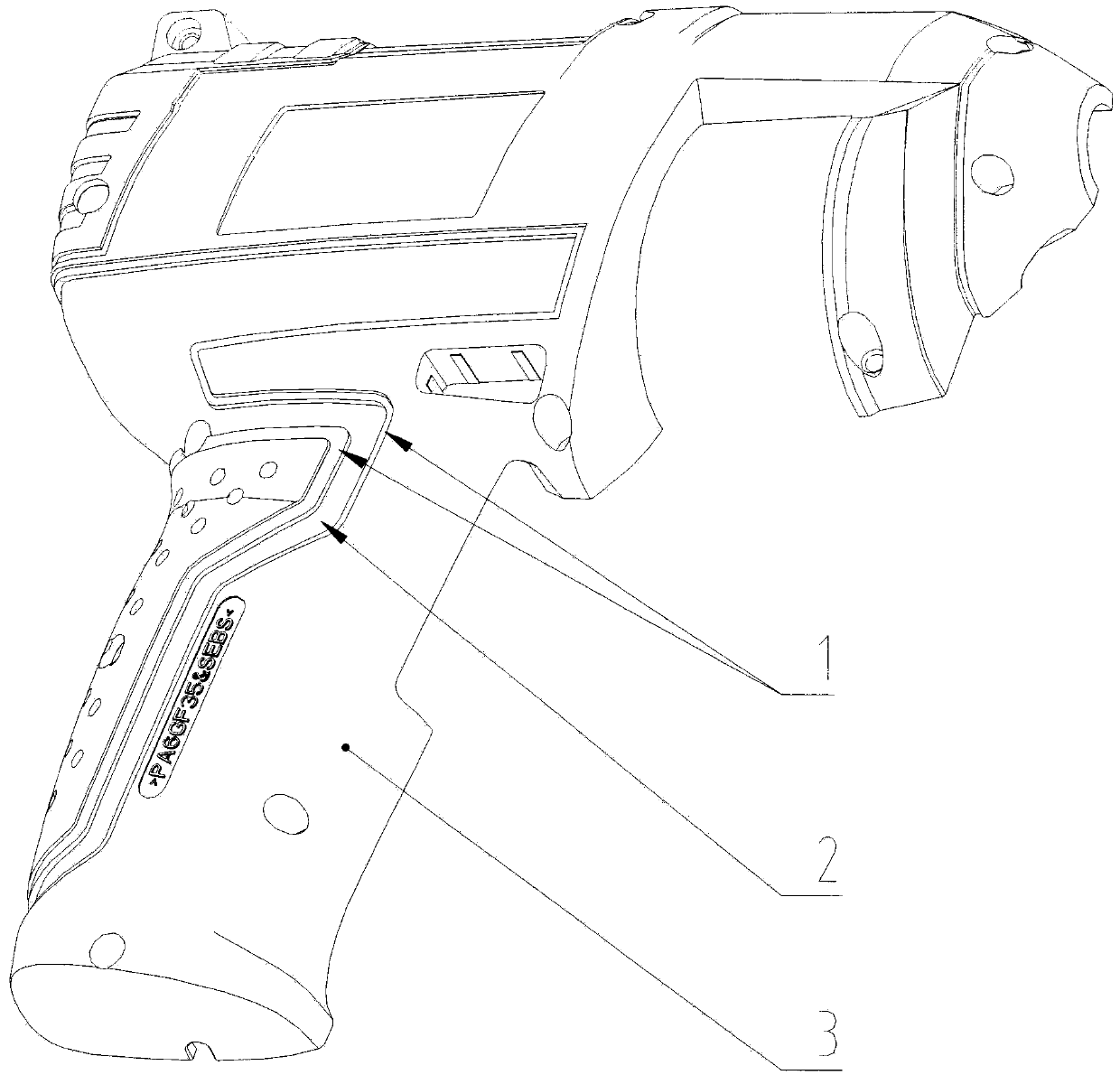

Over mold structure used for long and thin region on tool handle

A handle, slender technology, applied in the field of mold structure of injection molding products, can solve the problems of low injection molding pressure, large pressure loss, prone to trapped air, etc., to solve the exhaust problem, prevent glue overflow, and improve the quality of the product.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

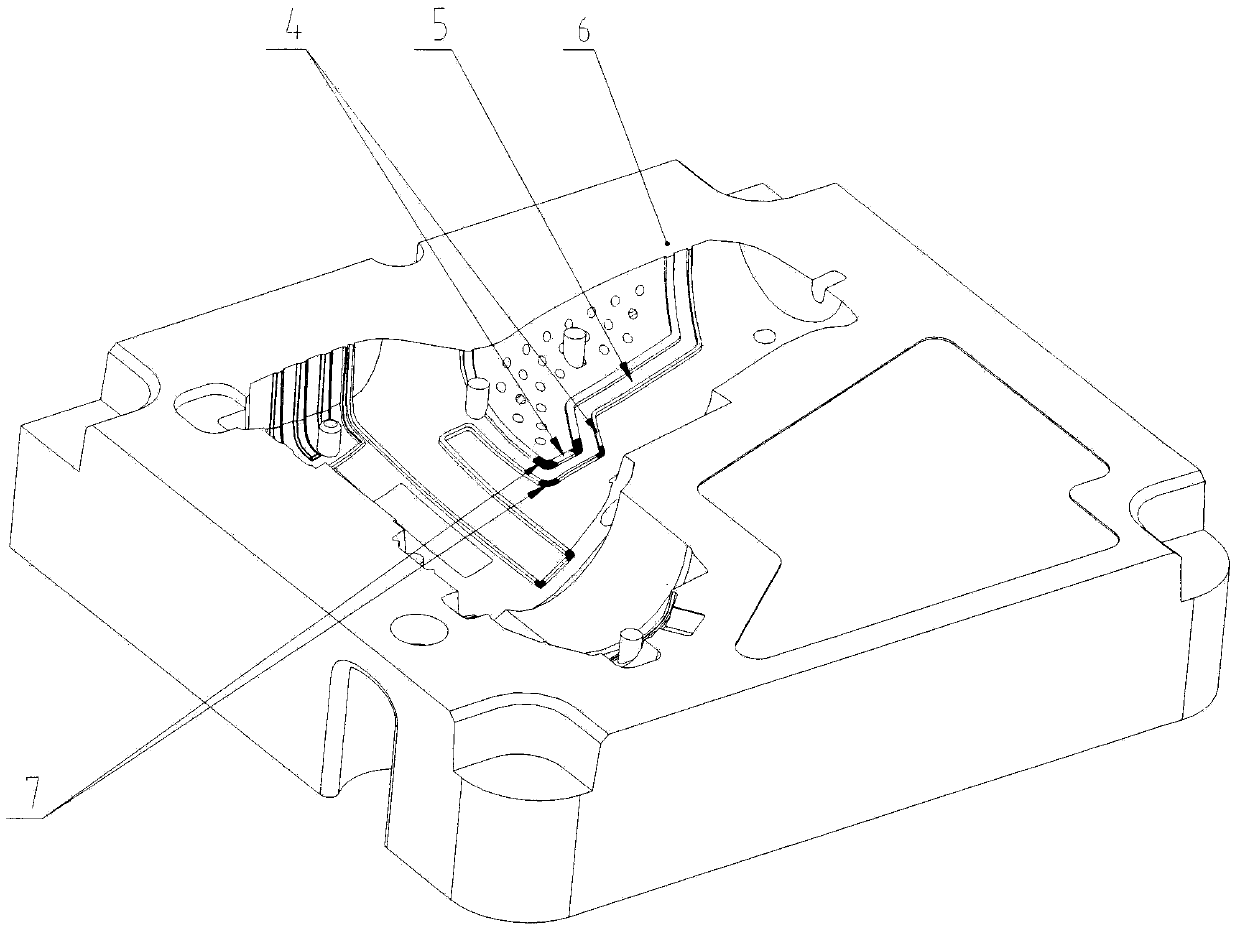

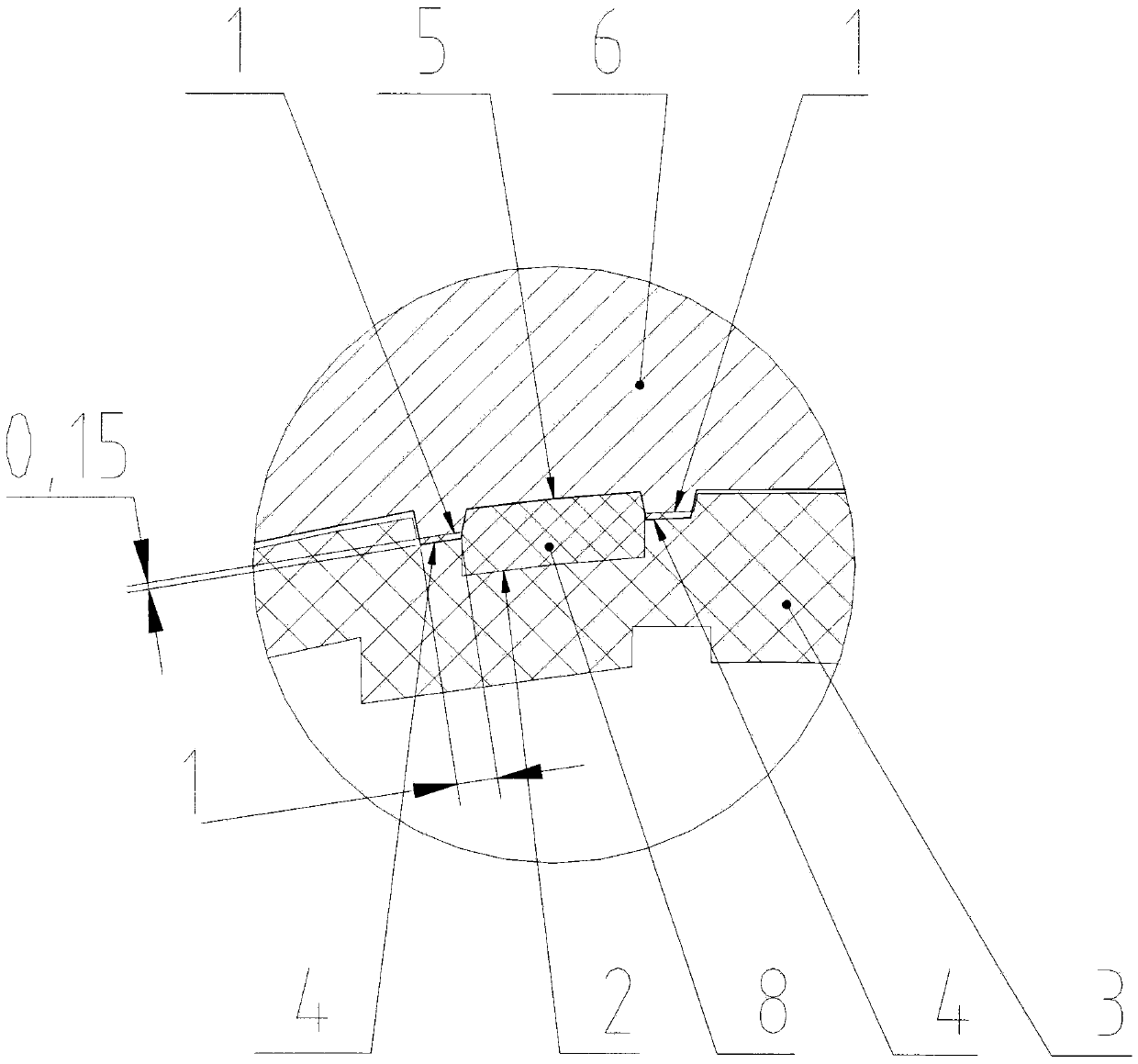

[0013] The present invention will be further described below in conjunction with the accompanying drawings and the embodiment of the right half tool handle.

[0014] Such as figure 1 , figure 2 and image 3 As shown, a body cavity surface 2 is provided on the part of the hard rubber body 3 that needs to be coated with soft rubber on the hard rubber body 3 of the right half tool handle, and a sealing groove 1 is opened on both sides of the body cavity surface 2; 6, the corresponding position that needs to be coated with soft glue is provided with a fixed mold core cavity surface 5, and both sides of the fixed mold core cavity surface 5 are provided with a sealing glue position 4. The raised height dimension of the sealing position 4 and the corresponding concave depth dimension of the sealing groove 1 are an interference fit when the mold is closed, so as to prevent the soft rubber 8 from overflowing during secondary injection molding.

[0015] Such as figure 2 As shown, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com