Patents

Literature

43results about How to "No crowding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

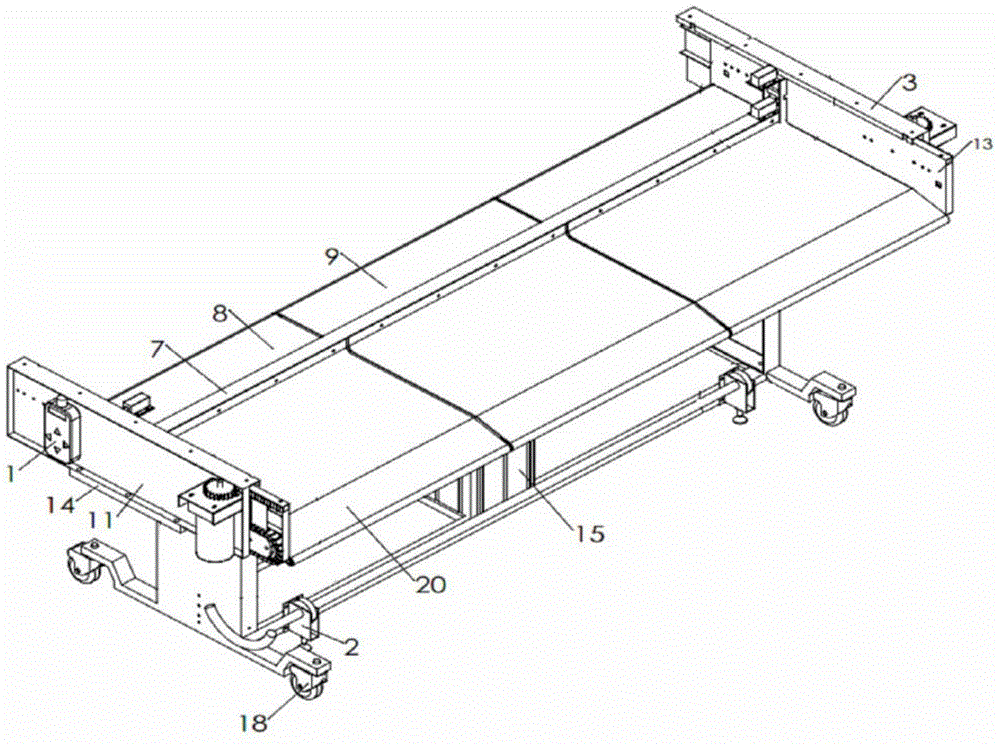

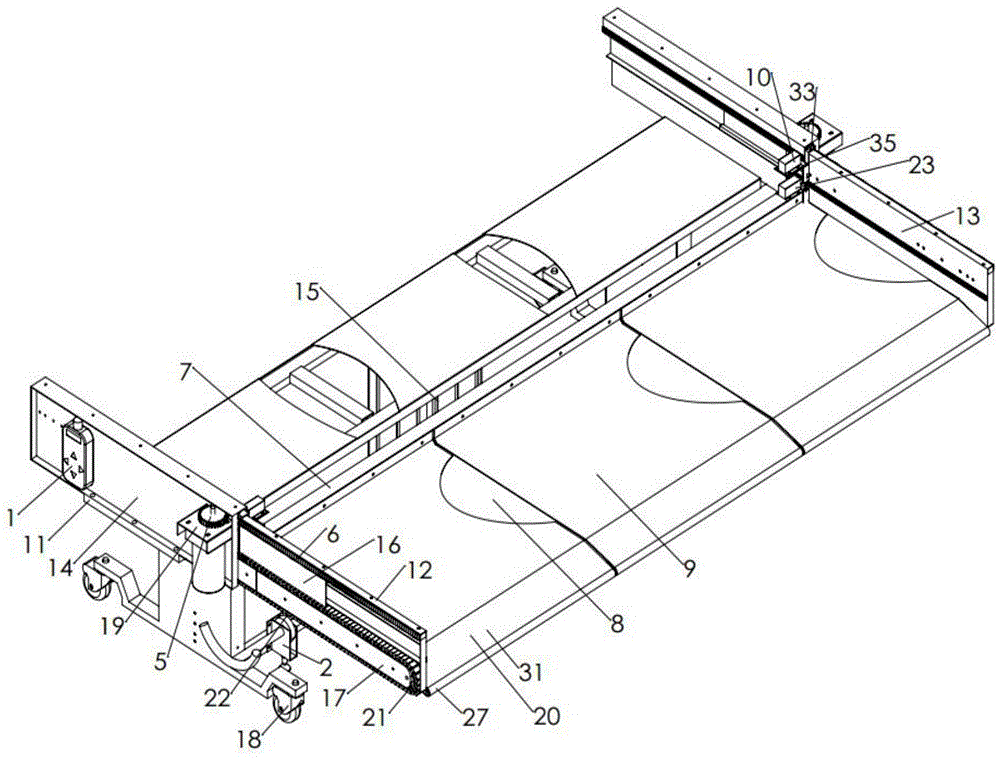

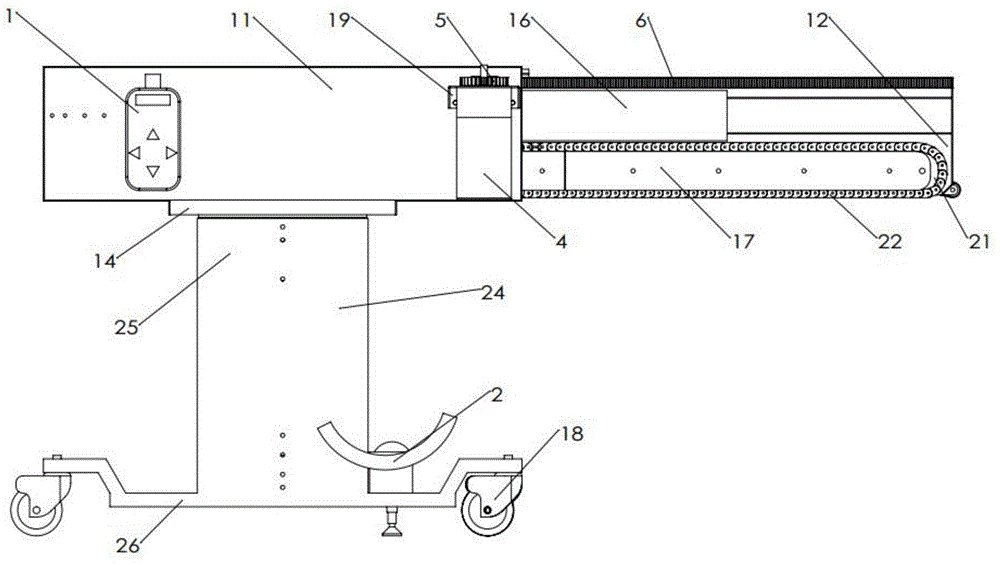

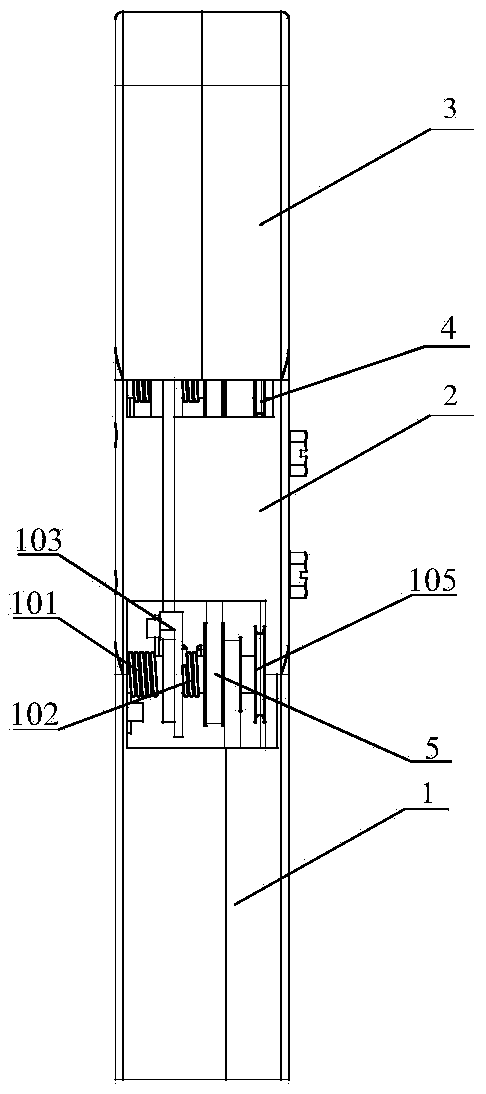

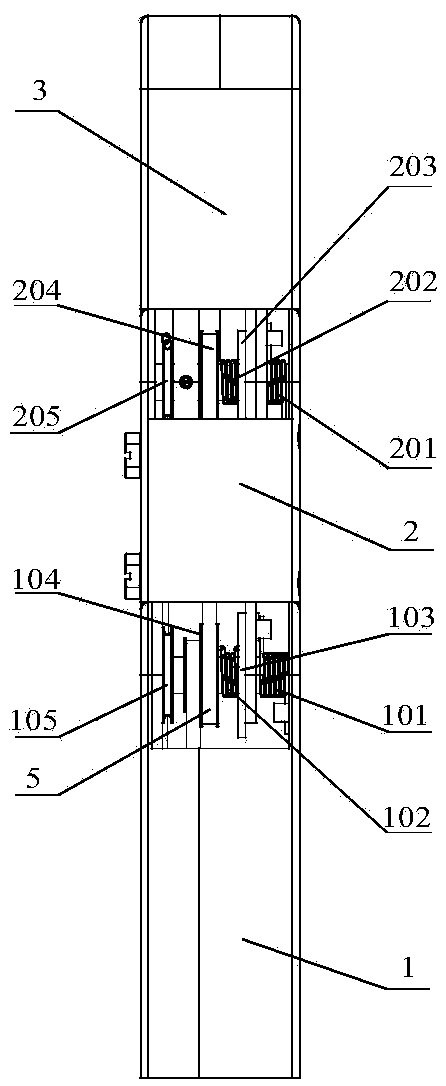

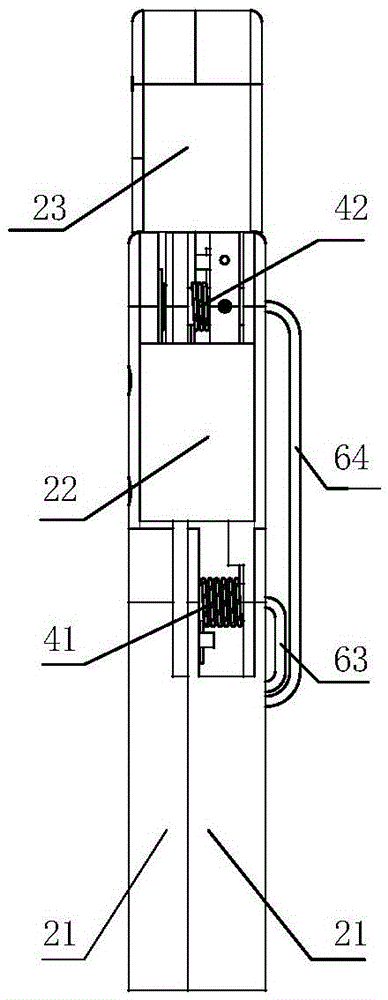

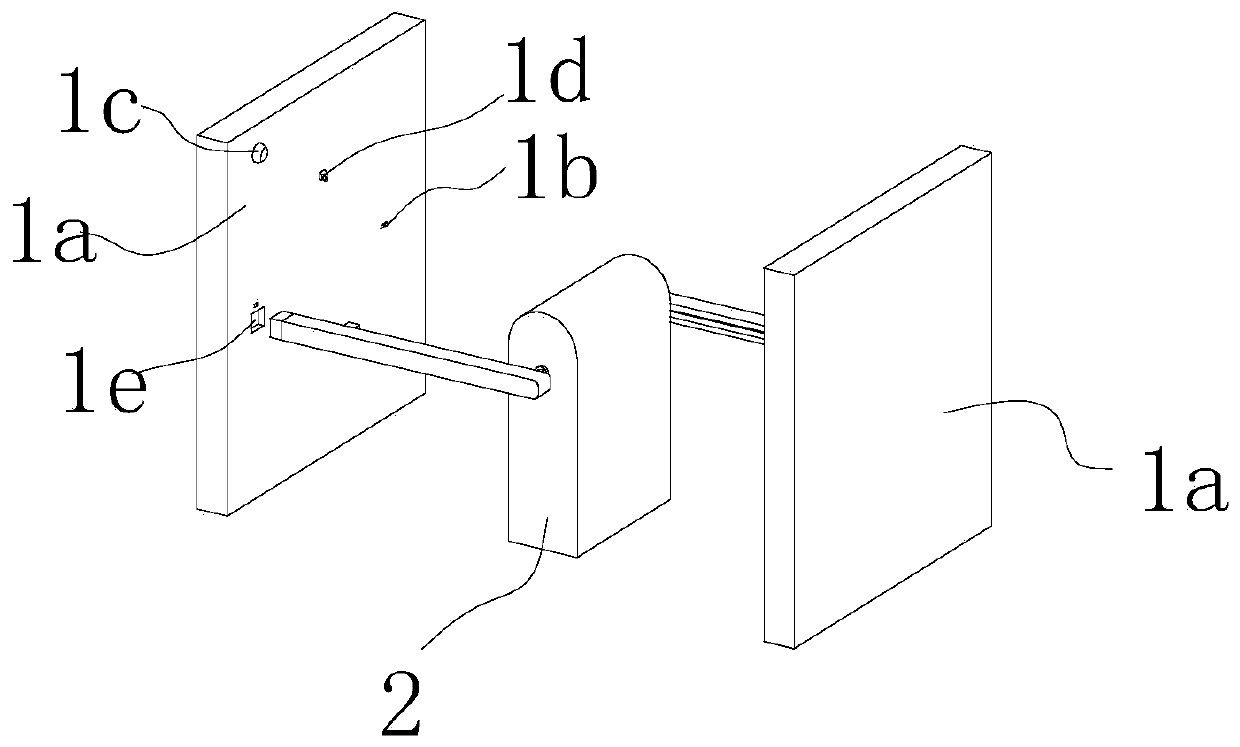

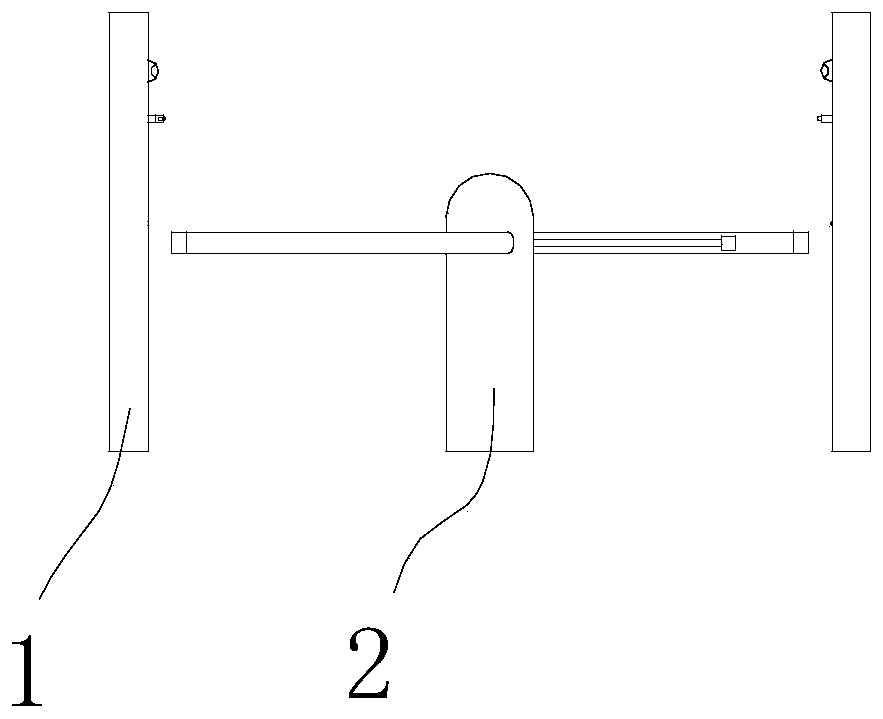

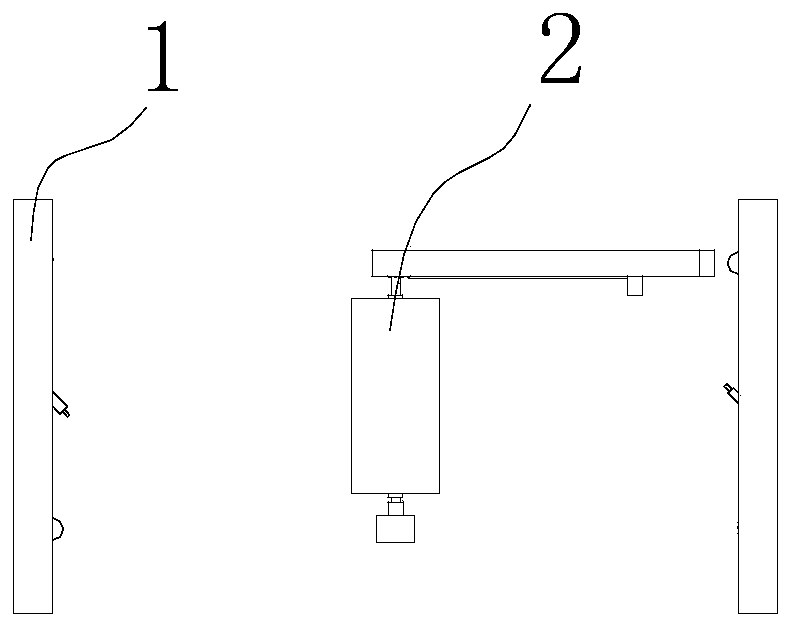

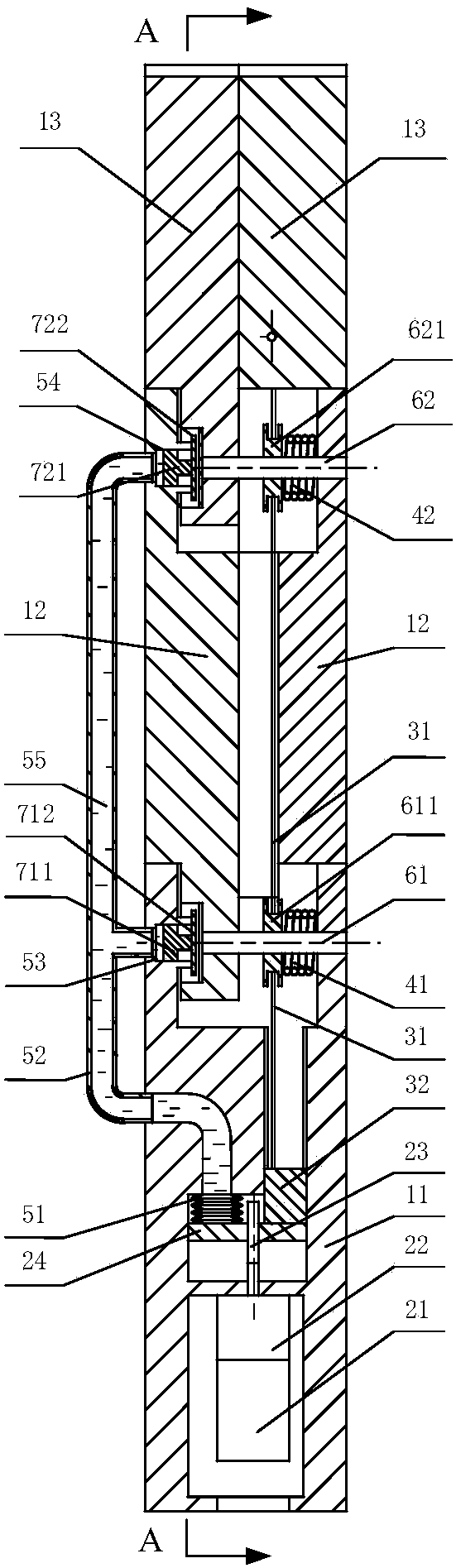

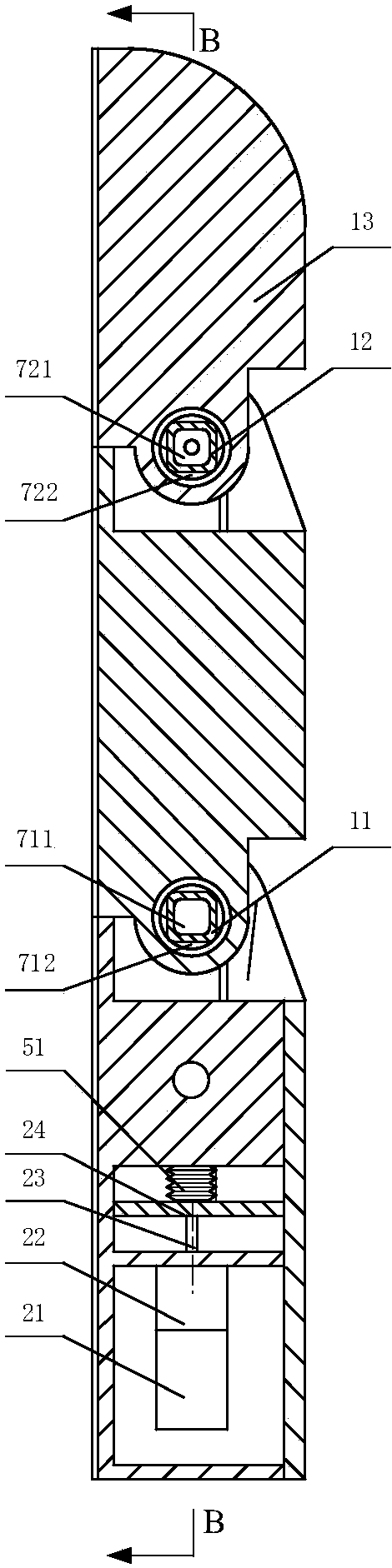

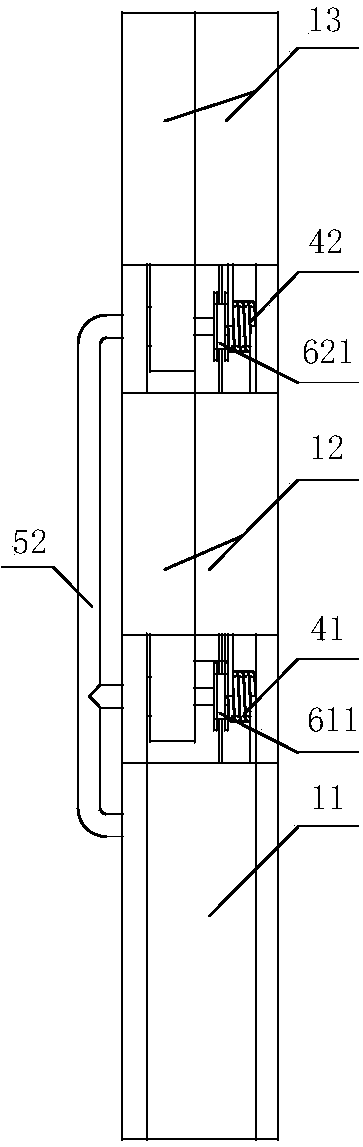

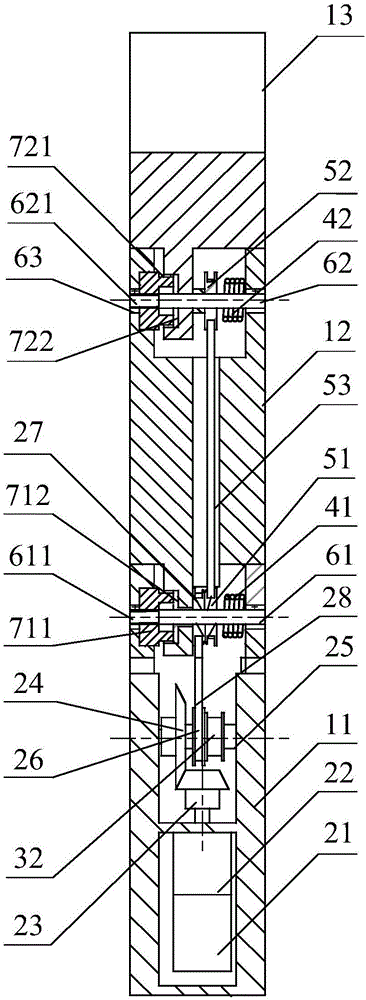

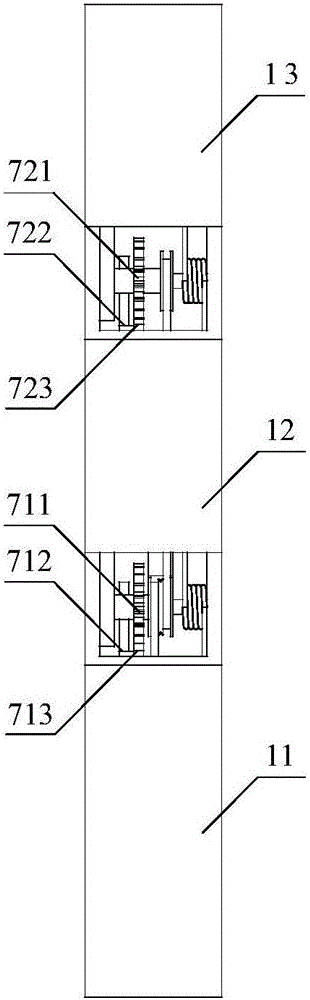

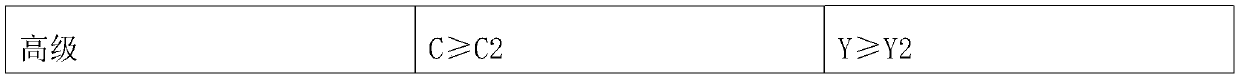

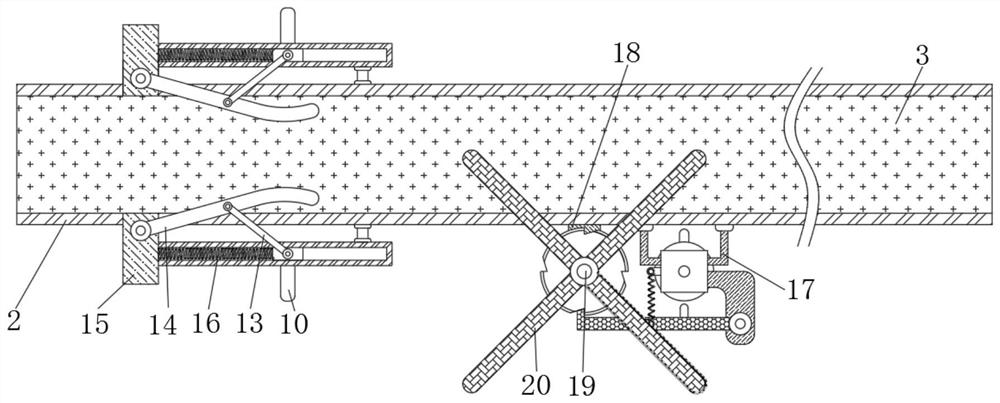

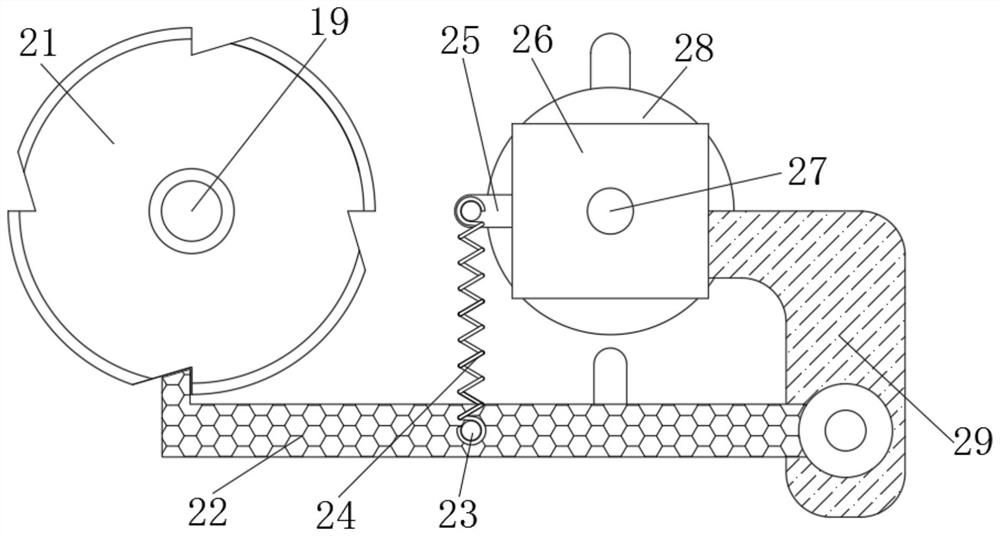

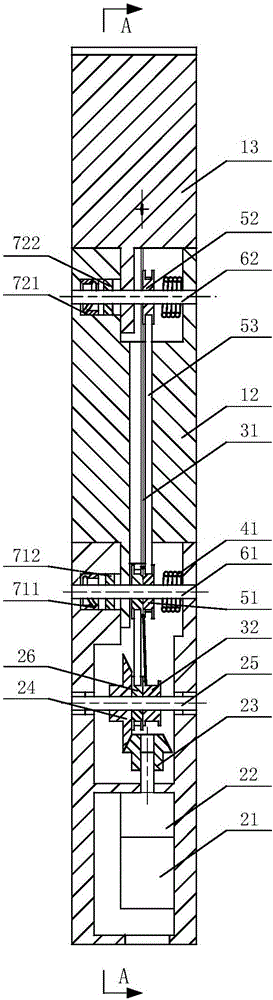

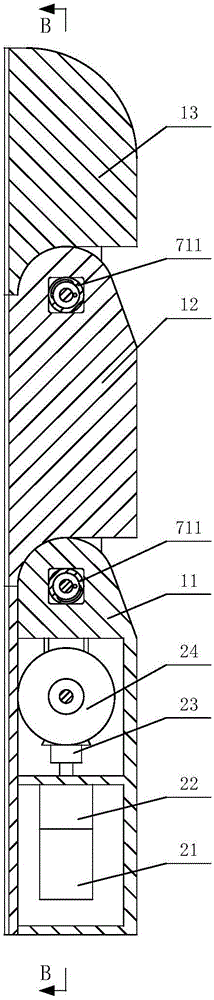

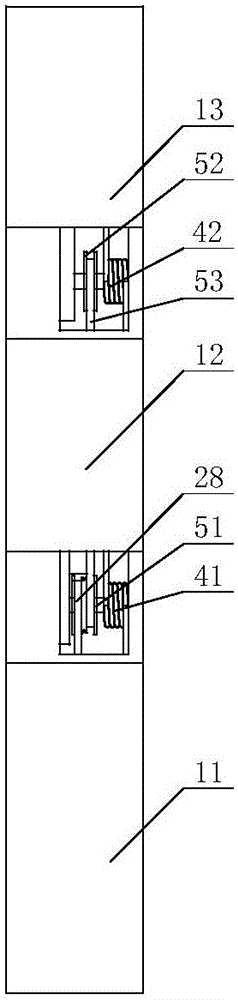

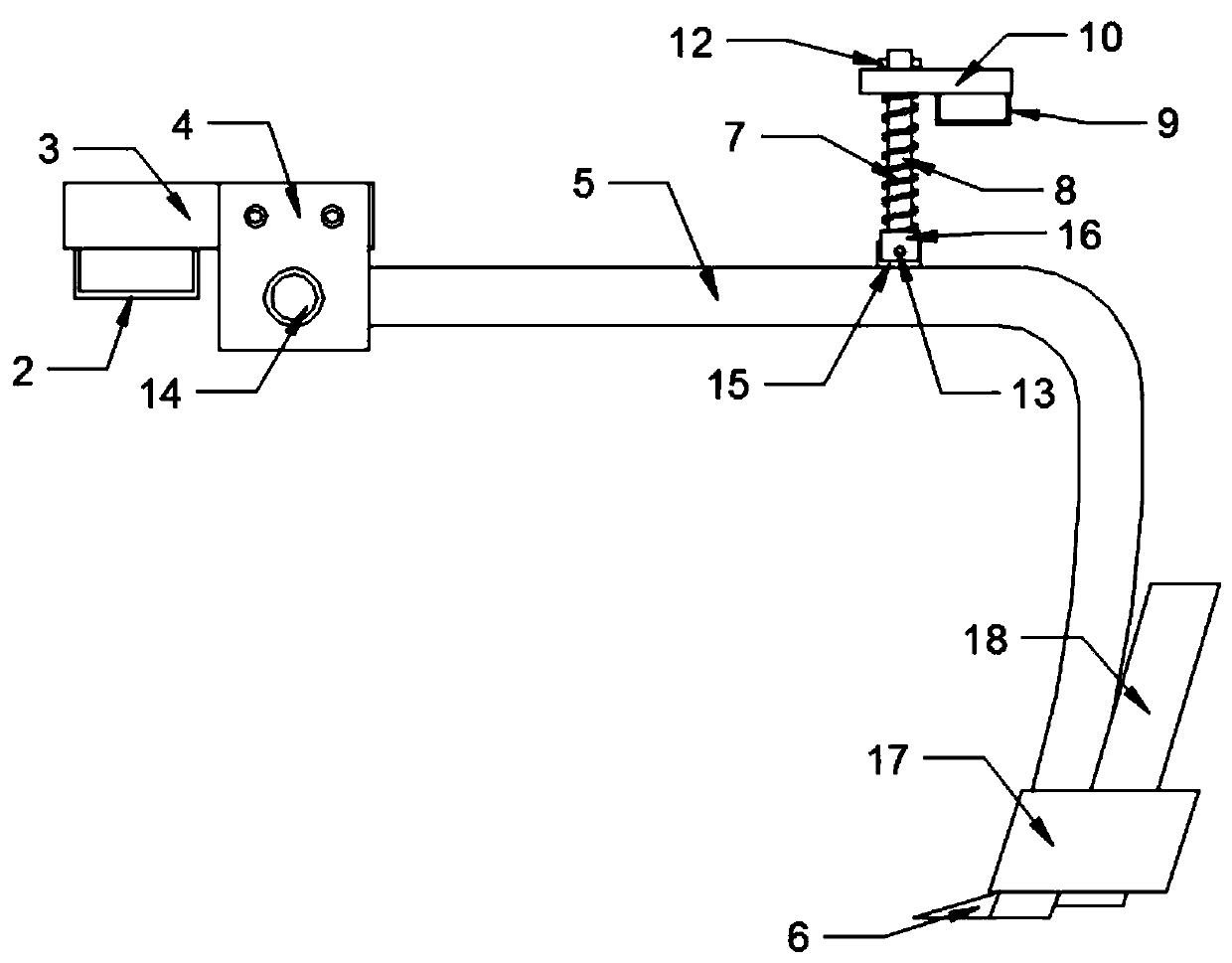

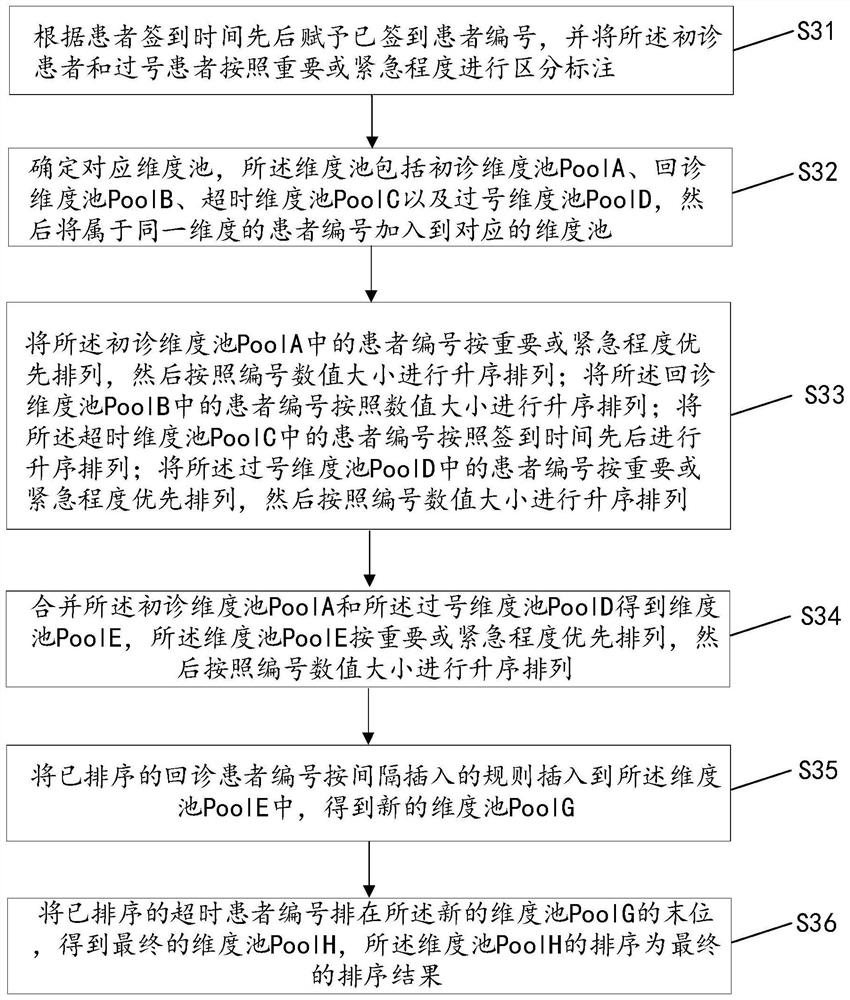

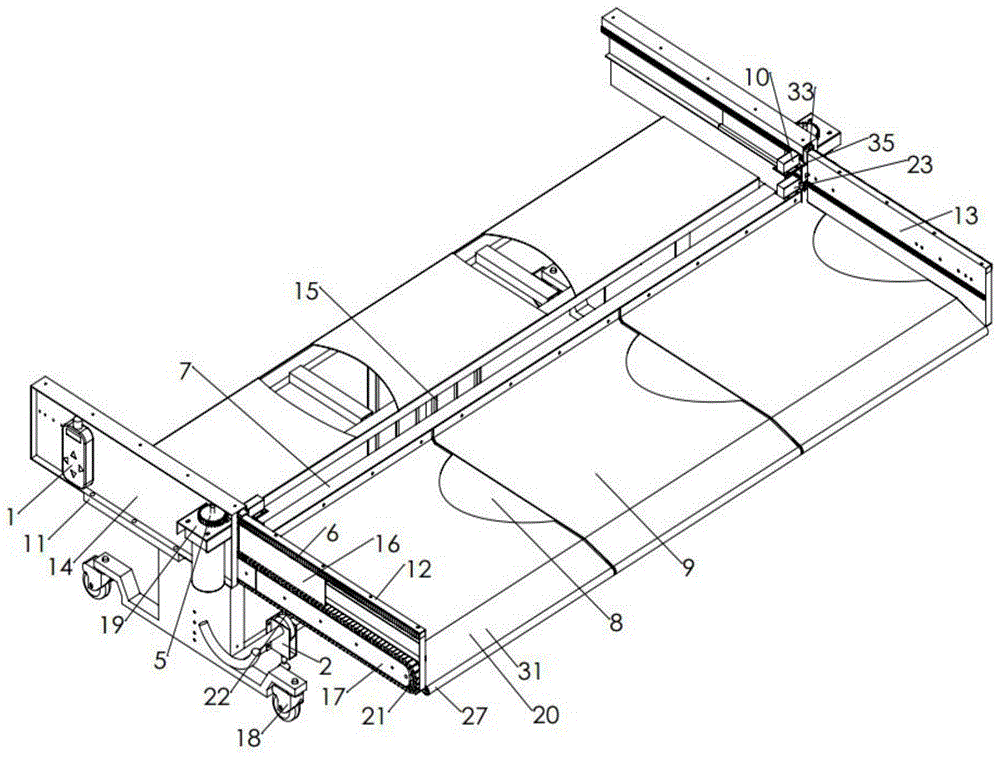

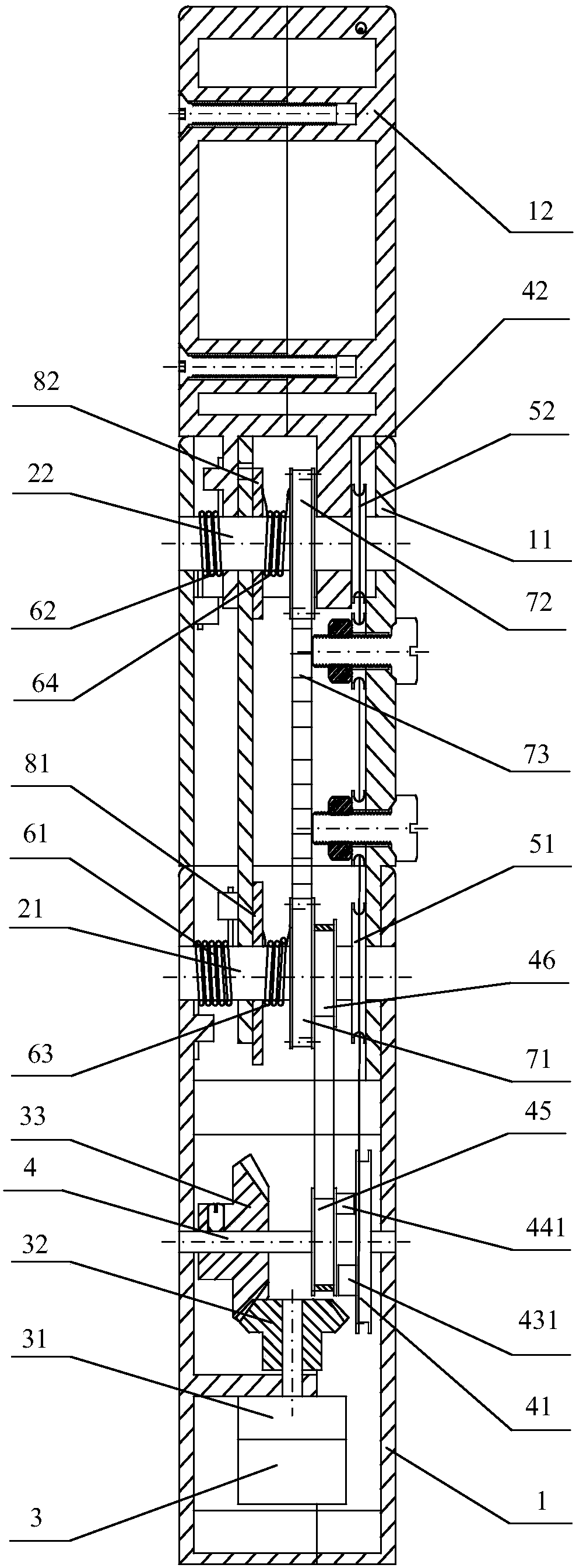

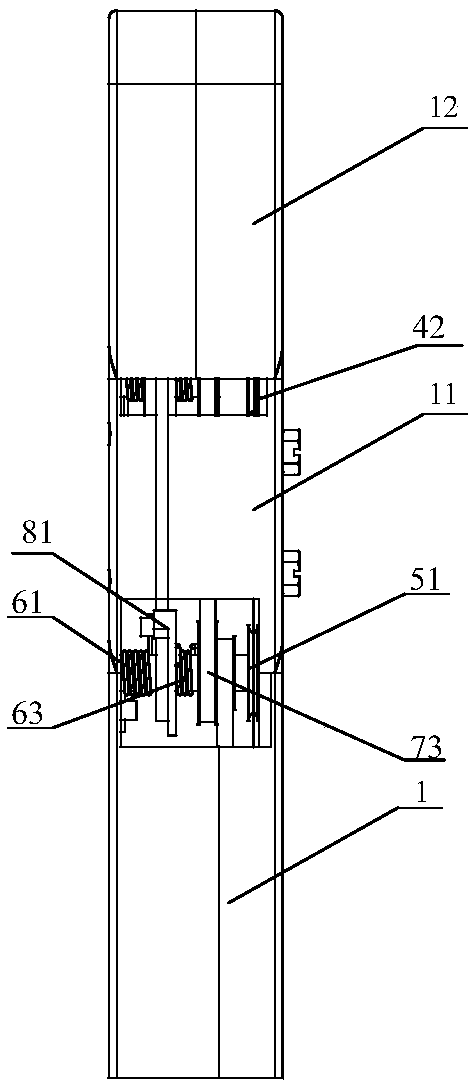

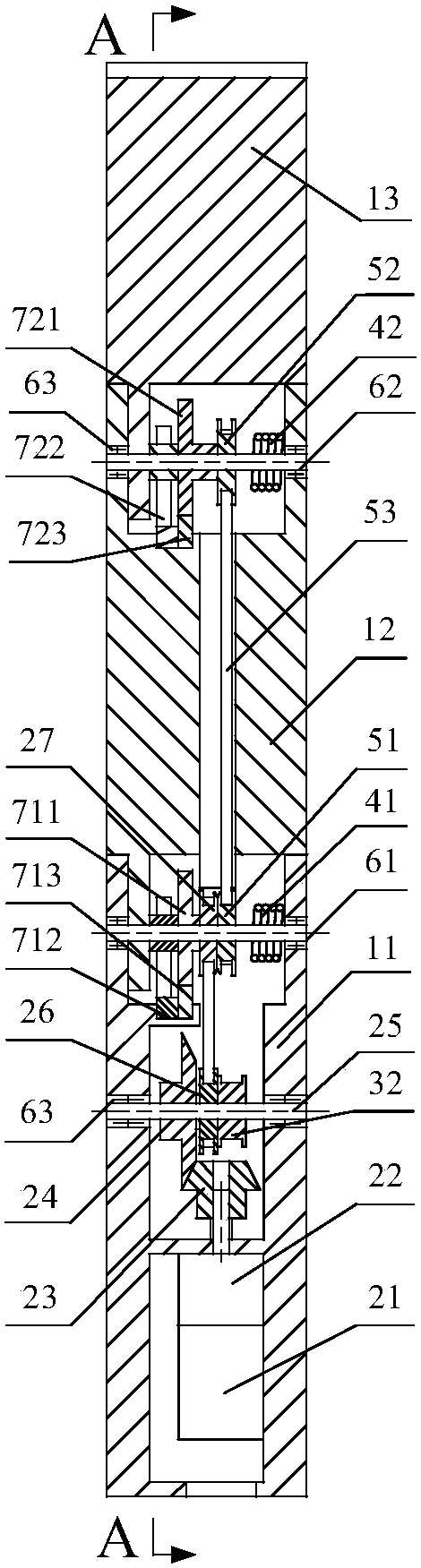

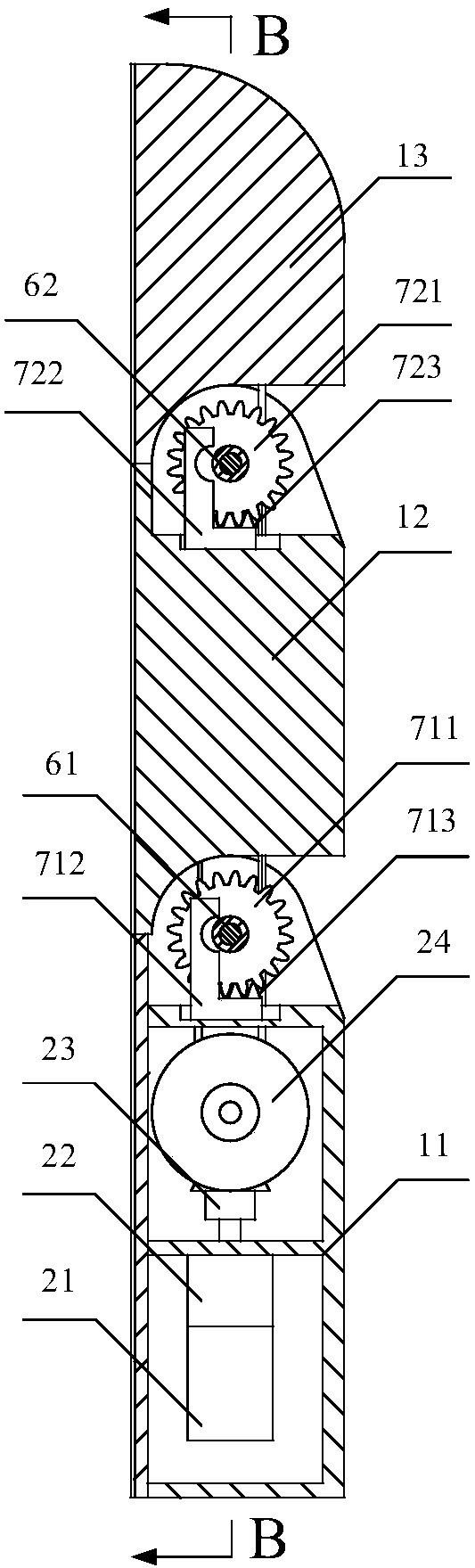

Patient ferry bed

The invention discloses a patient ferry bed which comprises a vehicle body, wherein the vehicle body is provided with a lifting mechanism and universal casters. The ferry bed that can move horizontally is installed on the vehicle body. The ferry bed comprises a bed board mechanism, a bed head and a bed tail beam mechanism. The patient ferry bed is of a single-layer mobile bed board structure and is simple in structure, needed parts are less, and the patient ferry bed is low in production cost and failure rate and convenient to maintain; the friction force caused by the single-layer mobile bed board structure is very small, a belt does not generate kinetic friction with the bed surface and the body of a patient, a bed sheet cannot be wound up, the safe transfer of the patient is achieved, and secondary injury is avoided; operators almost do not need to be in contact with the patient in the process, and the propagation of infecting bacteria is effectively avoided.

Owner:TIANJIN QIRUITONG TECH CO LTD

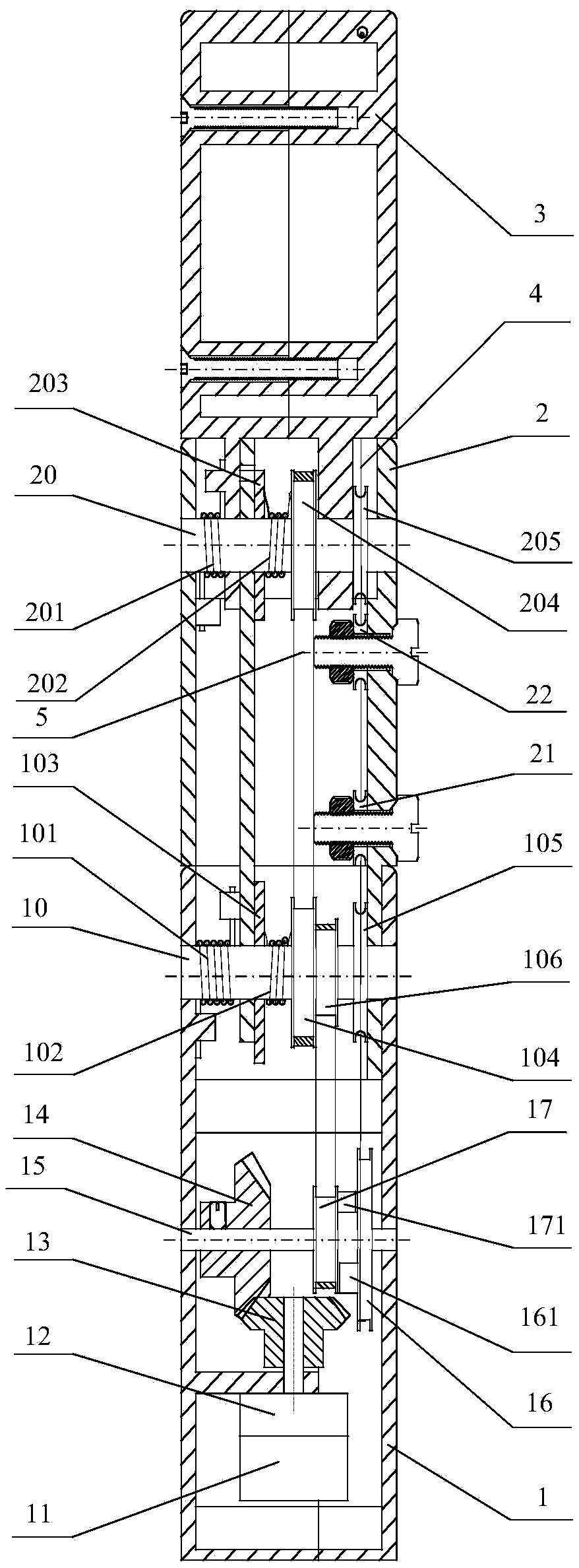

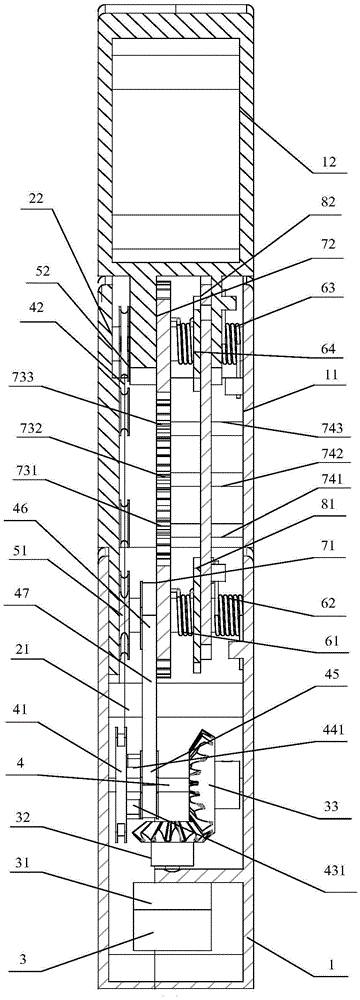

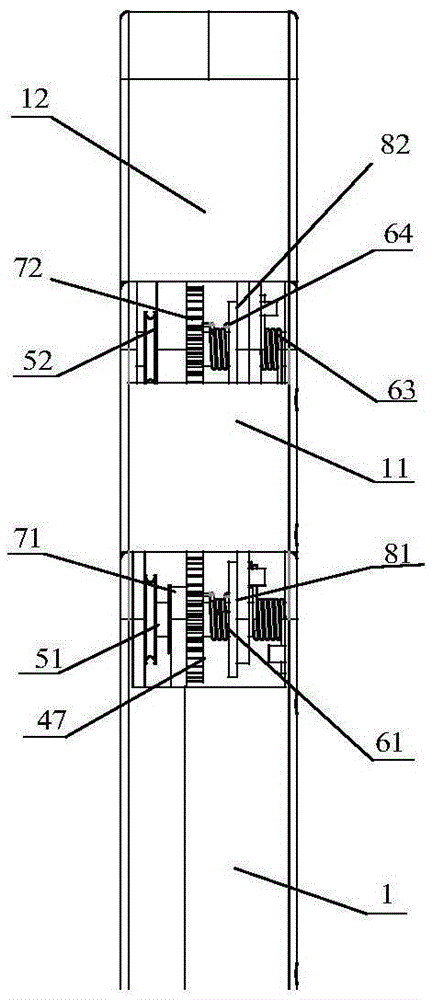

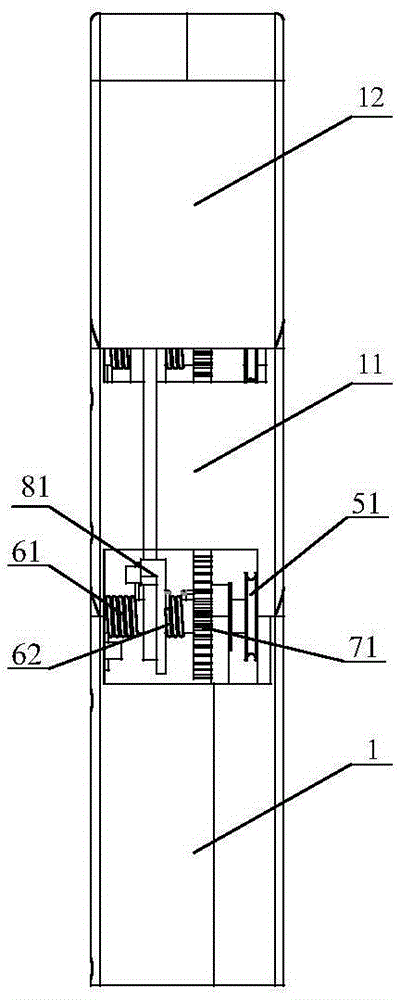

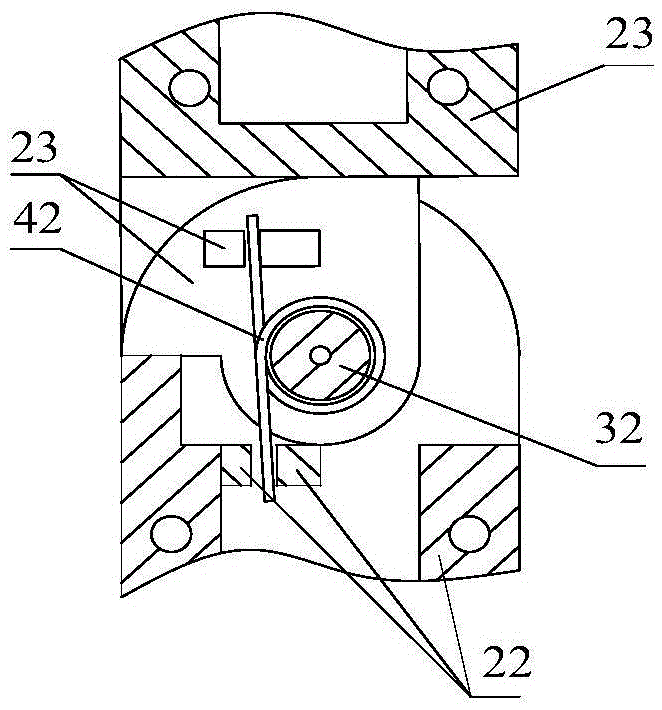

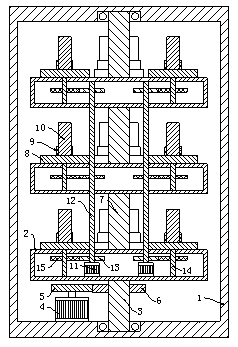

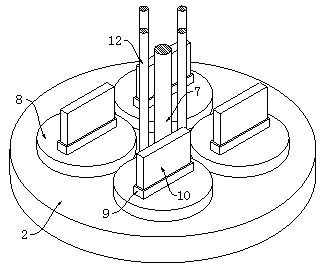

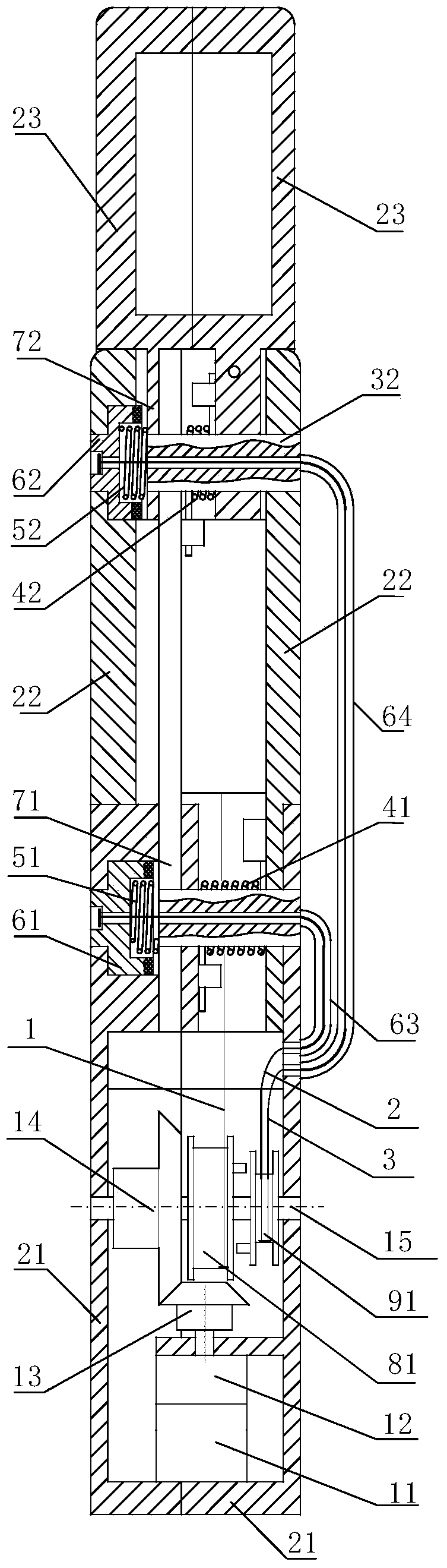

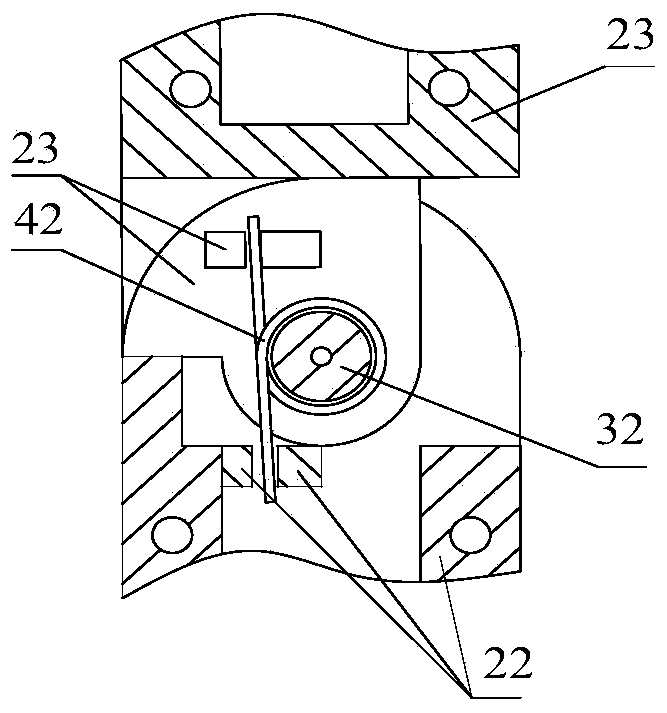

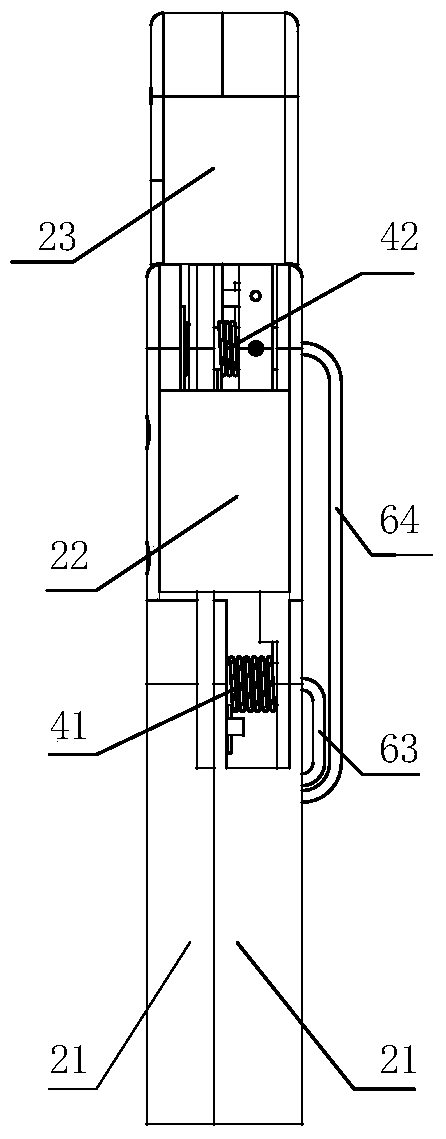

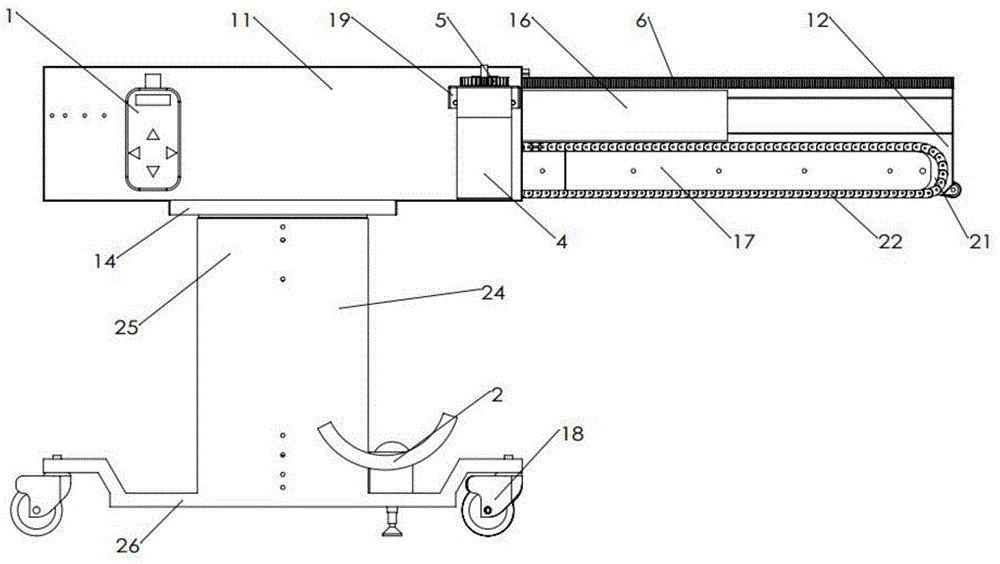

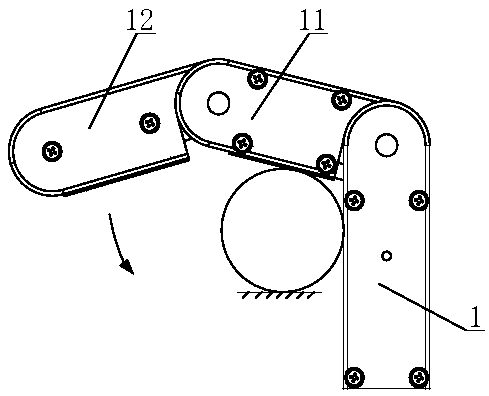

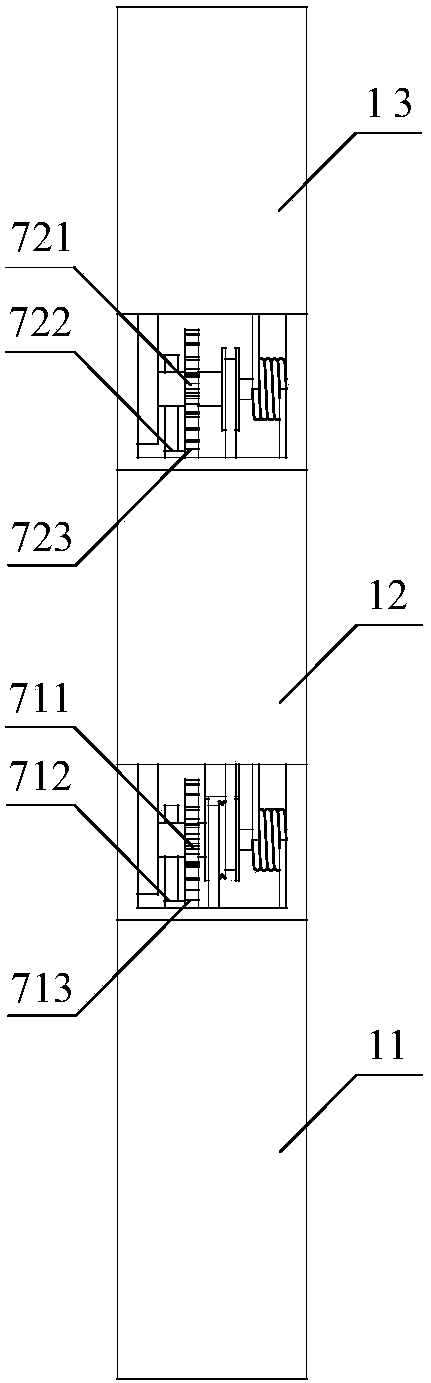

Belt wheel type cooperative locking linkage self-adaptive robot finger device

InactiveCN105364938APrevent rebound instabilityRebound instability will not occurJointsGripping headsRobot handDrive wheel

The invention discloses a belt wheel type cooperative locking linkage self-adaptive robot finger device, and belongs to the technical field of robot hands. The belt wheel type cooperative locking linkage self-adaptive robot finger device comprises a motor, a transmission mechanism, a plurality of finger sections, a plurality of joint shafts, a plurality of joint reed pieces, a plurality of linkage reed pieces, a tendon rope, a plurality of driving wheels, a plurality of driven wheels, a plurality of transmission pieces, a plurality of poking wheels and a plurality of poking pieces. The device utilizes the motor, the transmission mechanism, the poking pieces, the poking wheels, the driving wheels, the driven wheels, the transmission pieces, stay rope pieces, the tendon rope and the reed pieces for comprehensively realizing the functions of self-adaptive grabbing and continuous locking of a plurality of joints. The device is used for grabbing objects, and can automatically adapt to the shapes and the sizes of the objects; after the objects are grabbed, a joint locking mode or unlocking mode can be adopted; the grabbing process is fast and stable, the joints are locked after grabbed to prevent the instability of finger rebound, and greater grabbing force can be supplied; the locked joints are continuous in angles; and the device is simple in structure, small in size, light in weight, easy to be controlled and low in manufacturing and maintenance cost.

Owner:TSINGHUA UNIV

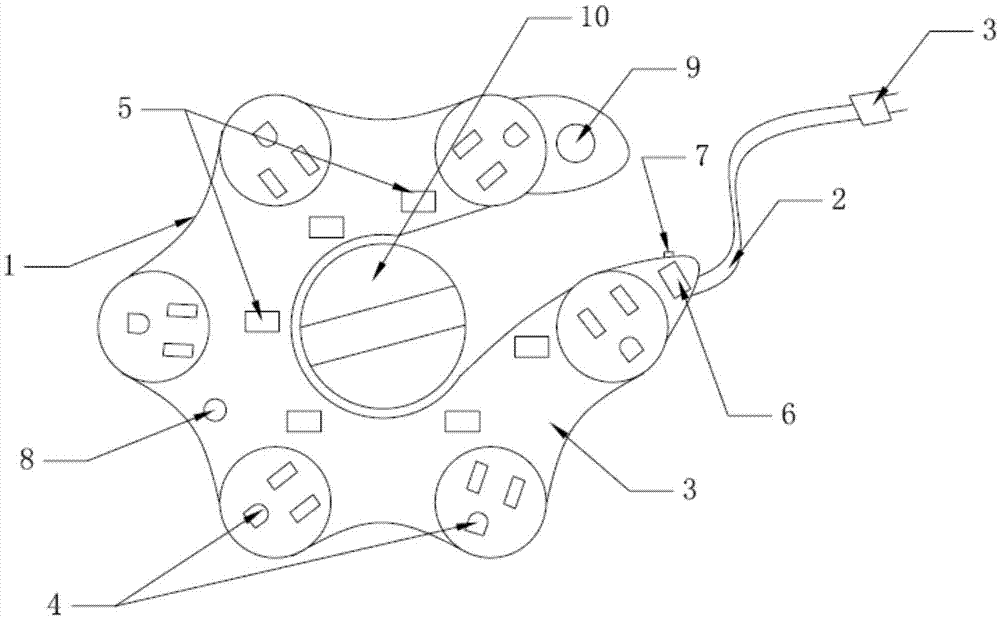

Intelligent electric rail car traffic network system

ActiveCN101332820APrecise speed controlAvoid traffic accidentsRailway componentsRailway stationTraffic networkTraffic congestion

An intelligent electric rail vehicle traffic network system comprises a control center, a platform and an electric rail vehicle, and works out real time passenger flow transportation data by the operation sub-system of the control center arranged in the control center and forecasts the vehicle flow information of next time, thus being capable of better arranging the vehicle transportation work even if being capable of issuing an emergency traffic leading direction under a situation of traffic jam, besides, the electric rail vehicle and other vehicle meeting processing sub-systems can also carry out detection on the meeting intersection of the electric rail vehicle, thus completely avoiding a meeting accident from happening and greatly improving the running safety. Besides, the carriage of the electric rail vehicle is in a three-layer design without runways; each layer is not communicated either, thus having a high space utilization rate without waste, thereby greatly increasing the load of the passengers; besides, each row of seats of each layer at the two sides of the electric rail vehicle is correspondingly provided with a door; therefore, the passengers can easily get on and off the vehicle without a crowding situation. Besides, the platform consists of a left platform and a right platform, the passengers of each layer get on and off the vehicle according to the same direction that is preset, the order is improved greatly as well; besides, the platform of each layer is provided with a display screen which is used for displaying the number, the empty seats of the carriage and the positions of the empty seats of the electric trail vehicle entering the station, and the like, the passengers can select the seats according to demands and stand on the corresponding platform for waiting, thus being very convenient.

Owner:陈笠

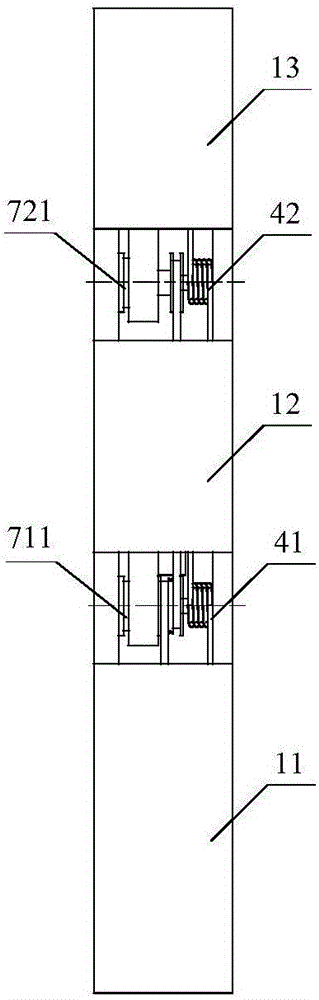

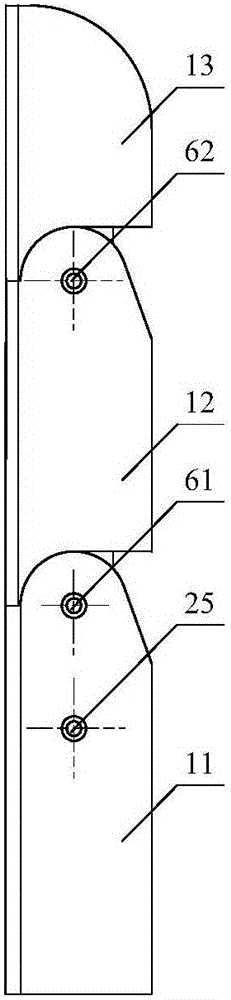

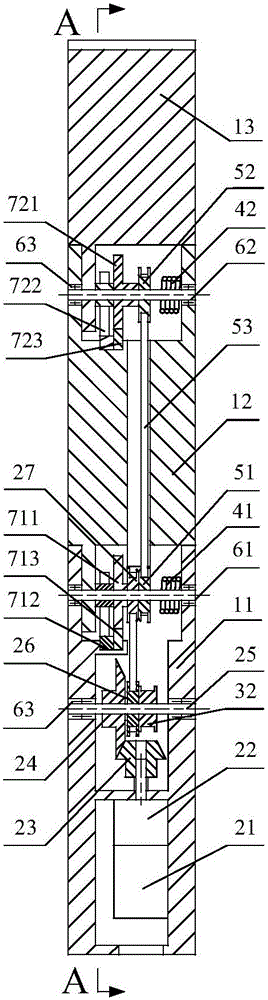

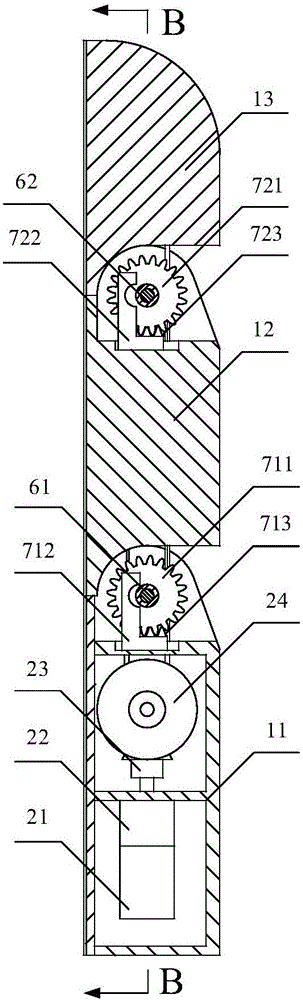

Gear type self-adaptive robot finger device with rope and springs assisting in grabbing

InactiveCN105583837APrevent rebound instabilityRebound instability will not occurGripping headsRobot handEngineering

The invention provides a shaft-drive spiral synchronous locking self-adaptive robot finger device and belongs to the technical field of robot hands. The self-adaptive robot finger device comprises a motor, multiple finger segments, multiple joint shafts, multiple springs, a tendon rope, a rope pull piece, multiple joint wheels, multiple sets of nut sliding blocks, threaded rods and multiple sets of wheel type transmission mechanisms. The motor, the tendon rope, the springs, the wheel type transmission mechanisms and a threaded transmission mechanism are adopted for the self-adaptive robot finger device to comprehensively achieve the self-adaptive grabbing function and the function of locking multiple joints continuously and synchronously. The self-adaptive robot finger device is used for grabbing objects and can be adaptive to shapes and sizes of the objects; the joint locking manner or the joint unlocking manner can be adopted after the objects are grabbed; the grabbing process is quick and stable, the joints are locked after the objects are grabbed, fingers are prevented from springing back and losing stability, and larger grabbing force can be provided; the multiple joints can be locked synchronously; the lockable joint angle is continuous; and the self-adaptive robot finger device is simple in structure, small in size, low in weight, easy to control and low in design, manufacture, assembly and maintenance cost.

Owner:TSINGHUA UNIV

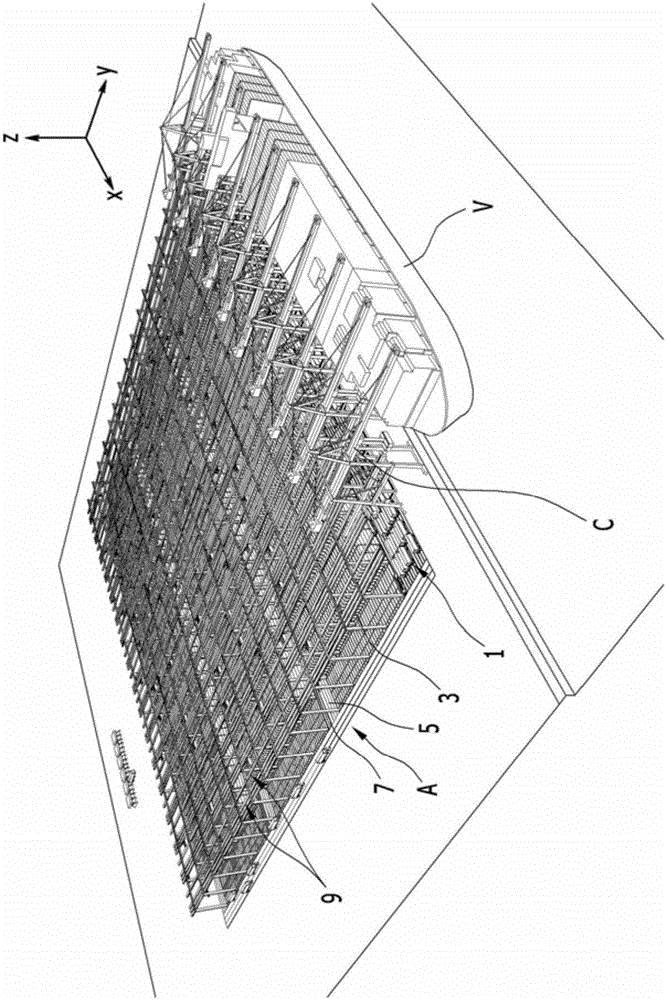

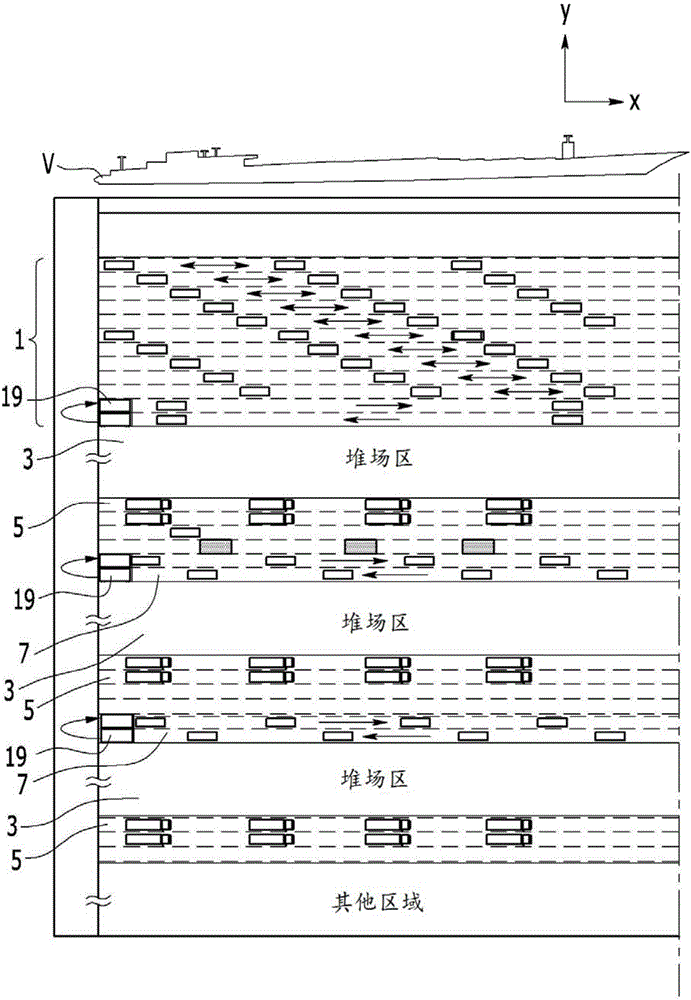

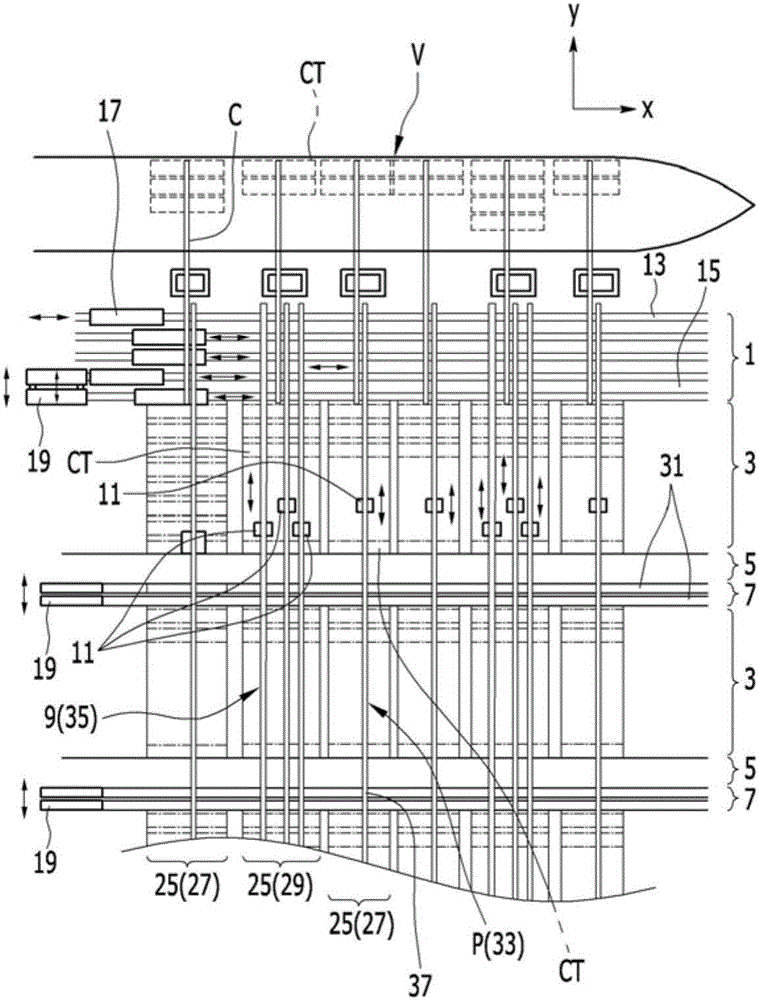

Container terminal system

InactiveCN106232510ASave loading and unloading timeReduce movementStorage devicesLoading/unloadingEngineeringMechanical engineering

The present invention provides a container terminal system capable of efficiently loading, unloading, and storing containers in a container terminal or capable of moving containers into / out of a container terminal. The container terminal system according to the present invention comprises: a main automatic transfer area arranged near a quay wall such that containers are transferred in a direction parallel with the quay wall; a yard area adjacent to the main automatic transfer area, containers being stored in the yard area; a vehicle transfer area arranged adjacent to the yard area; an overhead rail unit installed over the main automatic transfer area, the yard area, and the vehicle transfer area in a direction perpendicular to the quay wall; and a shuttle for moving along the overhead rail unit and transferring containers.

Owner:KOREA MARITIME INST

Tendon-rope type lateral locking linkage self-adaption robot finger device

The invention discloses a tendon-rope type lateral locking linkage self-adaption robot finger device and belongs to the technical field of robot hands. The tendon-rope type lateral locking linkage self-adaption robot finger device comprises a motor, a speed reducer, a transmission mechanism, a main tendon rope, N finger sections, N-1 joint shafts, N-1 joint spring members, N-1 joint wheels, a first pull rope member, N-1 joint sliding blocks, N-1 friction blocks, N-1 locking tendon ropes, N-1 locking spring members and a second pull rope member, wherein N is a natural number which is greater than one. The device is used for grabbing objects and achieves the functions of self-adaption grabbing and continuous and synchronous locking of multiple joints. The grabbing process is rapid and stable, and the joints are locked after grabbing, so that fingers are prevented from springback instability, and large grabbing force can be provided. The multiple joints can be synchronously locked and lockable joint angles are continuous. The device is simple in structure, small in size, low in weight, easy to control and low in design, manufacturing, assembly and maintenance cost.

Owner:TSINGHUA UNIV

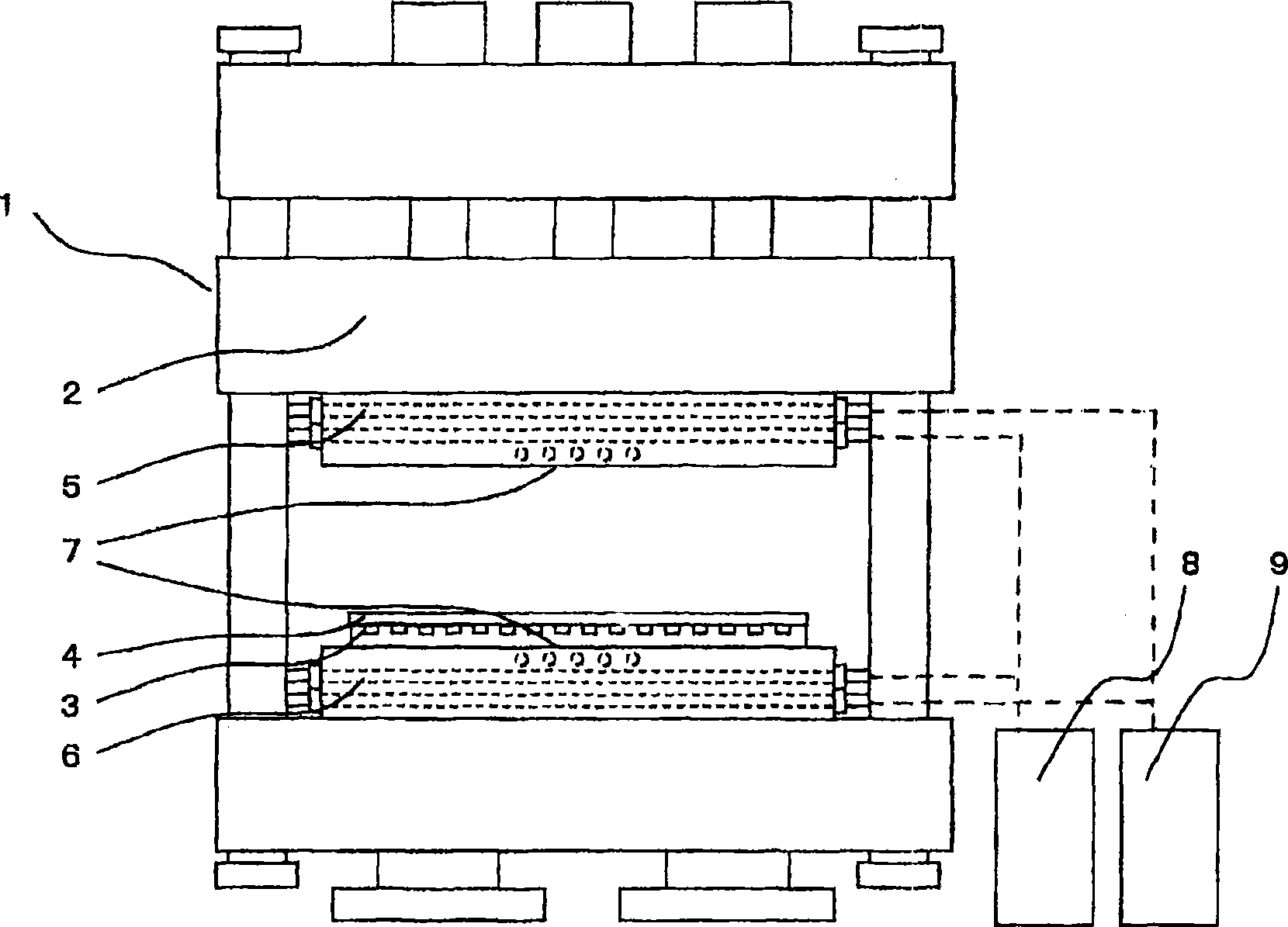

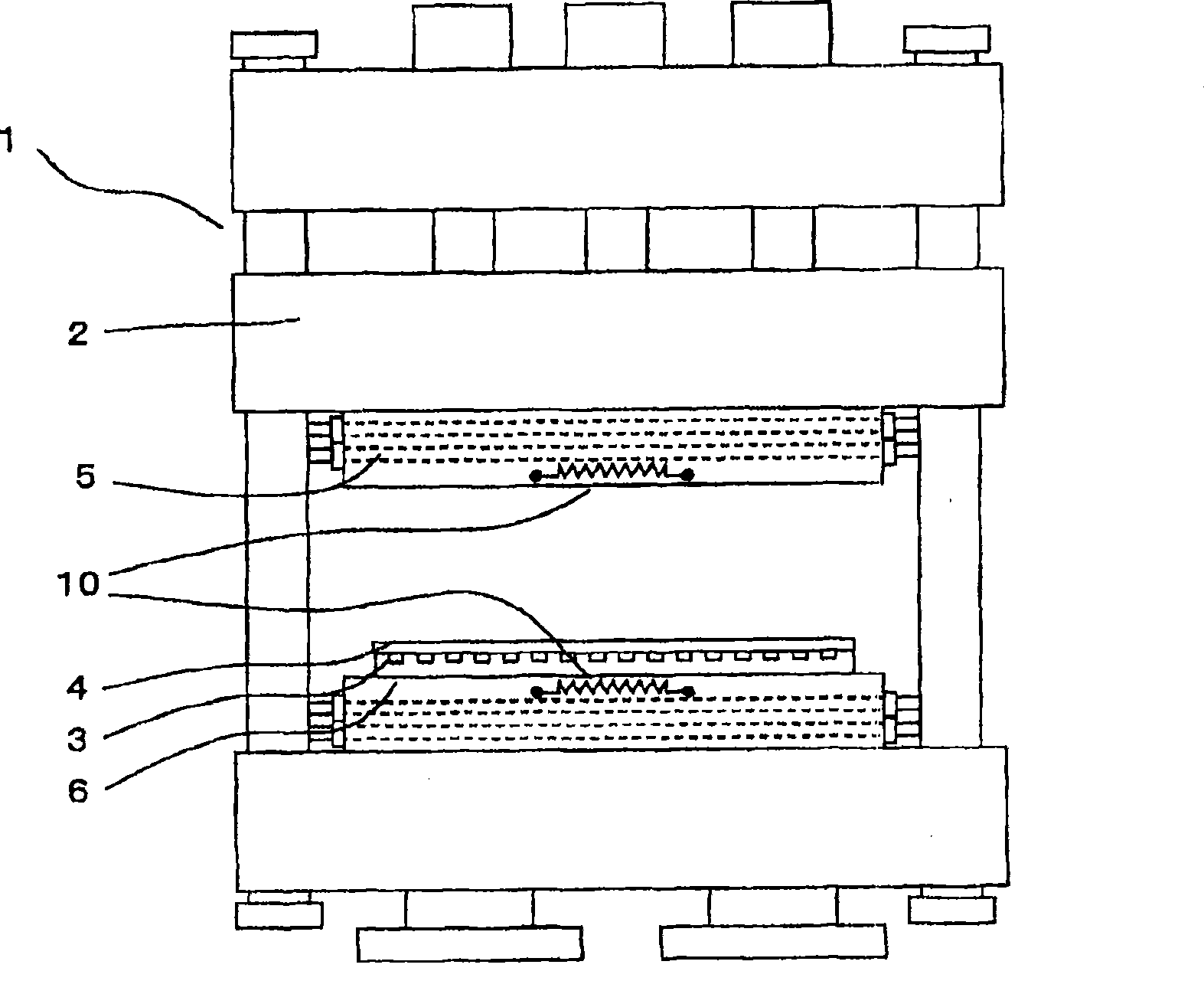

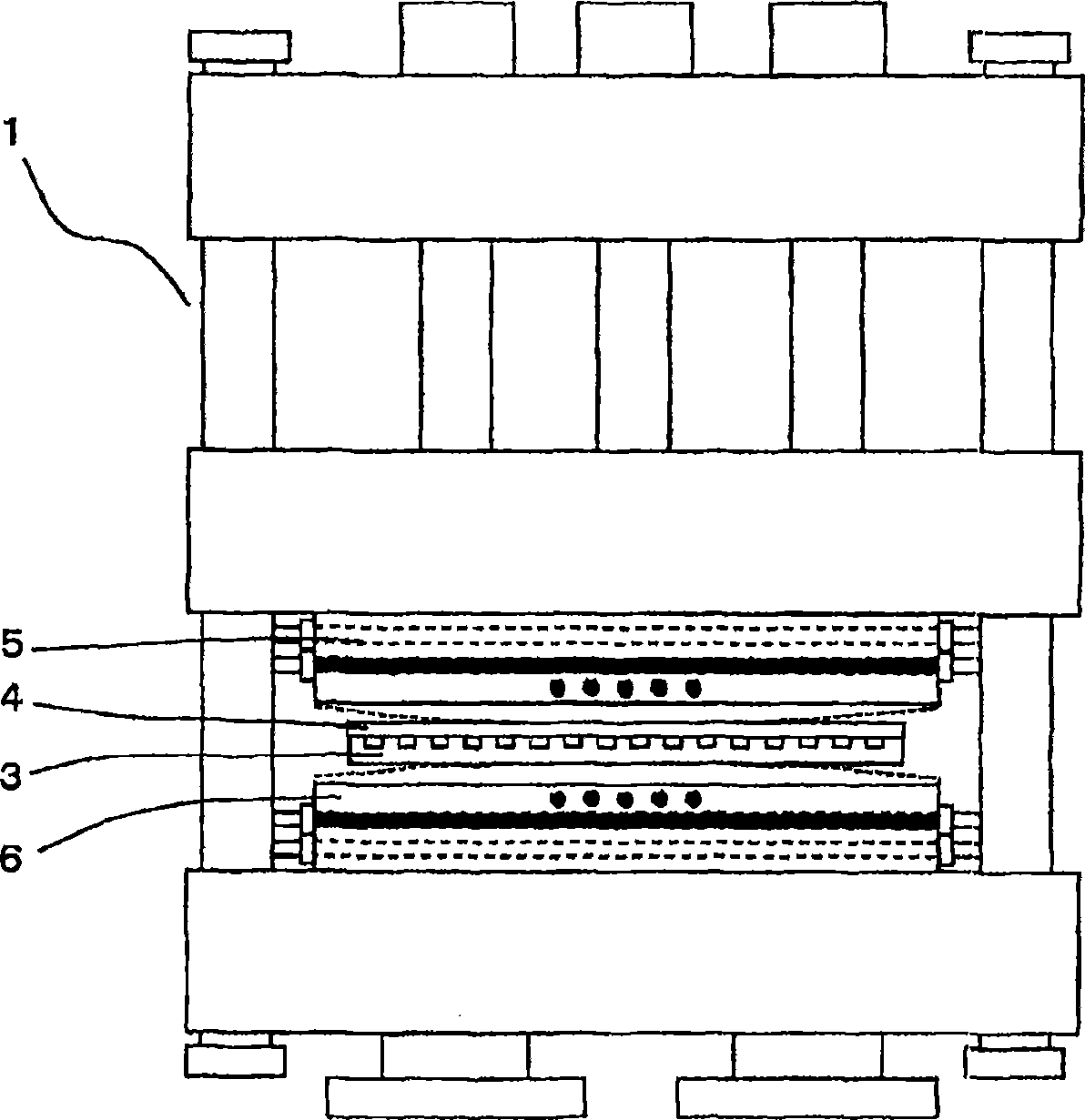

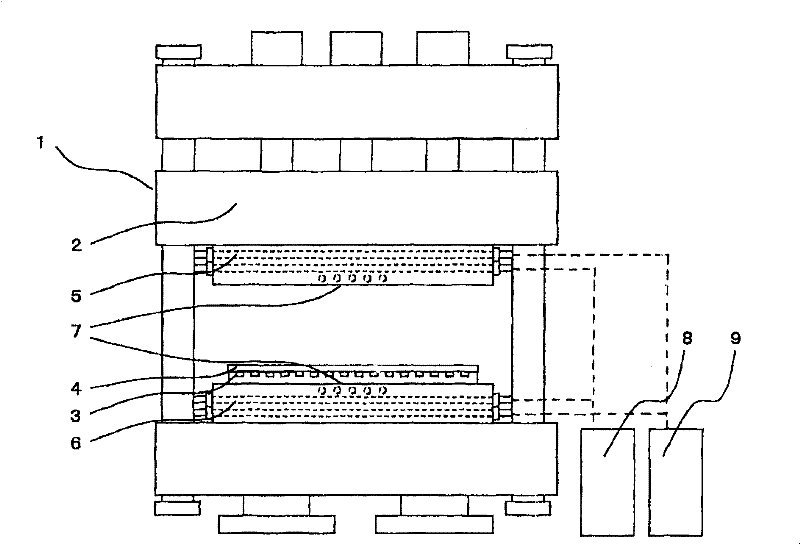

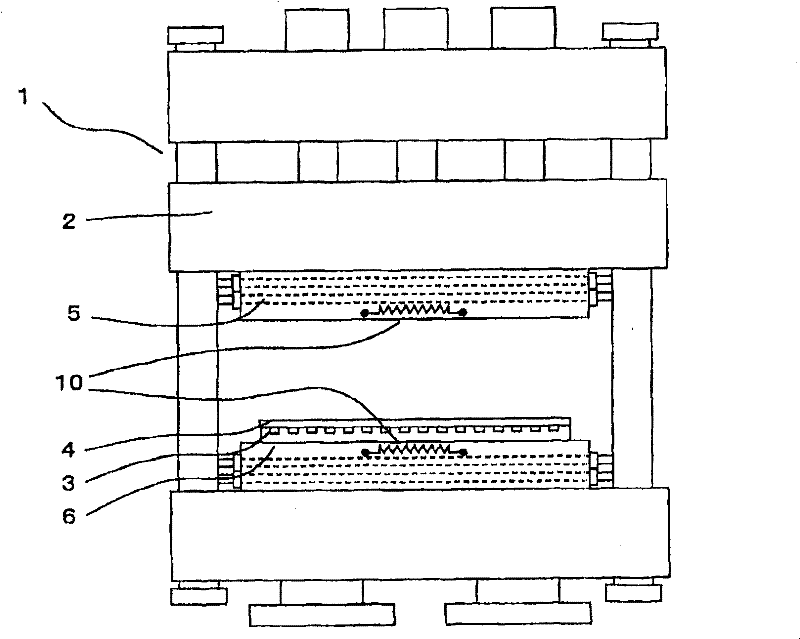

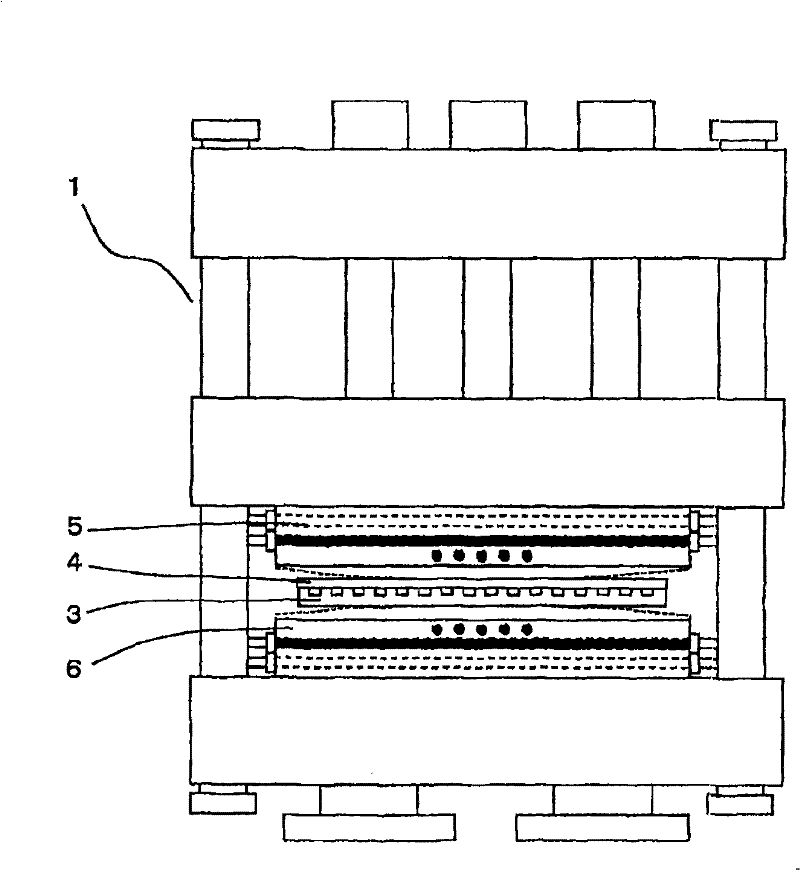

Process for producing microconfiguration transfer sheet and apparatus therefor

A process for producing a sheet and apparatus therefor that in the operation of heating a sheet substratum and a metal mold with fine uneven configuration, bringing them into mutual contact and pressurizing the same so as to form the fine uneven configuration on a surface of the sheet substratum, avoid transfer failure attributed to air trapping at the transfer face between the metal mold and the sheet substratum to thereby obtain a sheet having the desired fine uneven configuration formed on its surface. There are provided a process for producing a microconfiguration transfer sheet, and apparatus therefor, comprising, in the microconfiguration transfer sheet producing operation including heating a sheet substratum and a metal mold with fine uneven configuration, bringing them into mutual contact and pressurizing the same so as to form the fine uneven configuration on a surface of the sheet substratum, carrying out the configuration formation while changing the planarity of a configuration forming face consisting of at least one, or a combination, of a pair of pressurization plates or metal molds arranged so as to apply pressure to the sheet substratum and the metal mold.

Owner:TORAY IND INC

Garden road guiding system capable of being automatically started according to pedestrian flow

InactiveCN111104907ANo crowdingEase congestionCharacter and pattern recognitionTraffic restrictionsStructural engineeringMechanical engineering

The invention relates to the technical field of regional pedestrian volume dispersion, and particularly relates to a garden road guiding system which can be automatically started according to the pedestrian volume. The system comprises a pedestrian flow monitoring device and a pedestrian flow guiding device which are arranged at a road intersection, the pedestrian flow guiding device is arranged in the middle of the pedestrian flow monitoring device; an outlet and an inlet are formed between the pedestrian flow guiding device and the pedestrian flow monitoring device; the outlet and the inletare formed in two sides of the pedestrian flow guide device; two gate rods capable of swinging are arranged on the pedestrian flow guiding device; the two brake bars are respectively used for controlling the passing states of the entrance and the exit; under the condition that the road is crowded, the pedestrian flow guiding device is used for controlling the access condition of each intersectionof the road, so that the crowding degree of the road can be relieved to a certain extent, the people flow bearing capacity is improved, tourists are prompted, and dangerous accidents caused by personnel fullness are prevented.

Owner:金桓毅

Fluid stepless locking rope spring self-adaptive robot finger device

Owner:TSINGHUA UNIV

Axial spiral synchronous locking self-adaptive robot finger device

The invention provides an axial spiral synchronous locking self-adaptive robot finger device and belongs to the technical field of robot hands. The axial spiral synchronous locking self-adaptive robot finger device comprises a motor, a plurality of finger sections, a plurality of joint shafts, a plurality of spring pieces, a tendon rope, a rope drawing piece, a plurality of joint wheels, a plurality of sets of nut sliding blocks and screws, and a plurality of sets of wheel type transmission mechanisms. According to the axial spiral synchronous locking self-adaptive robot finger device, the functions of self-adaptive grabbing and continuous and synchronous locking of a plurality of joints are achieved comprehensively through the motor, the tendon rope, the spring pieces, the wheel type transmission mechanisms and threaded transmission mechanisms. The axial spiral synchronous locking self-adaptive robot finger device is used for grabbing objects and can automatically adapt to the shapes and sizes of the objects. A joint locking mode or a non-locking mode can be adopted after the objects are grabbed. The grabbing process is fast and stable, the joints are locked after grabbing, a finger is protected against rebounding and instability, and large grabbing force can be provided. The multiple joints can be locked synchronously. The angles of the joints capable of being locked are continuous. The axial spiral synchronous locking self-adaptive robot finger device is simple in structure, small in size, low in weight, easy to control, and low in design, manufacturing, assembling and maintenance cost.

Owner:TSINGHUA UNIV

Rack type multi-joint synchronous locking self-adaptation robot finger device

The invention discloses a rack type multi-joint synchronous locking self-adaptation robot finger device and belongs to the technical field of robot hands. The rack type multi-joint synchronous locking self-adaptation robot finger device comprises a motor, multiple finger sections, multiple joint shafts, multiple spring pieces, a tendon rope, a rope pulling piece, multiple joint wheels, multiple sets of gear and rack mechanisms and multiple sets of wheel type transmission mechanisms. By means of the device, the motor, the tendon rope, the spring pieces, the wheel type transmission mechanisms and the gear and rack transmission mechanisms are used for comprehensively achieving the function of self-adaptation grabbing and continuous synchronous locking of multiple joints. The device is used for grabbing objects and can automatically adapt to the shapes and the sizes of the objects; a joint locking manner or a joint non-locking manner can be adopted after the objects are grabbed; the grabbing process is fast and stable, the joints are locked after grabbing is conducted, fingers are prevented from rebounding to lose stability, and larger grabbing force can be provided; the multiple joints can be synchronously locked; joint angles which can be locked are continuous; and the device is simple in structure, small in size, light, easy to control and low in design, manufacturing, assembling and maintaining cost.

Owner:TSINGHUA UNIV

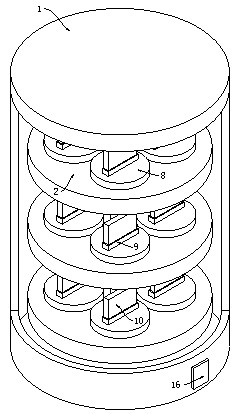

Display equipment for multiple kinds of plywood

The invention discloses display equipment for multiple kinds of plywood. The display equipment comprises a cabinet body and three display plates, the three display plates are located in the cabinet body and vertically distributed at equal intervals, and first rotation shafts are inserted in the top and bottom of an inner cavity of the cabinet body; the top of the first rotation shaft at the bottomof the cabinet body is fixedly connected with the bottom of the display plate at the bottom of the cabinet body, the bottom of the first rotation shaft at the top of the cabinet body is fixedly connected with the top of the display plate at the top of the cabinet body, and a first motor is fixedly arranged at one side of the bottom of the inner cavity of the cabinet body. According to the displayequipment, the cabinet body is transparent, clients can observe and compare with multiple kinds of plywood samples without walking and do not need to continuously walk for observation and comparison,if many clients exist, crowding cannot occur, and convenience is provided for the clients; in addition, the three display plates are placed in the cabinet body, it can be guaranteed that dust cannotfall on the surfaces of samples, frequent wiping is not needed, and convenience is provided for workers.

Owner:泗阳县翔宇包装材料厂

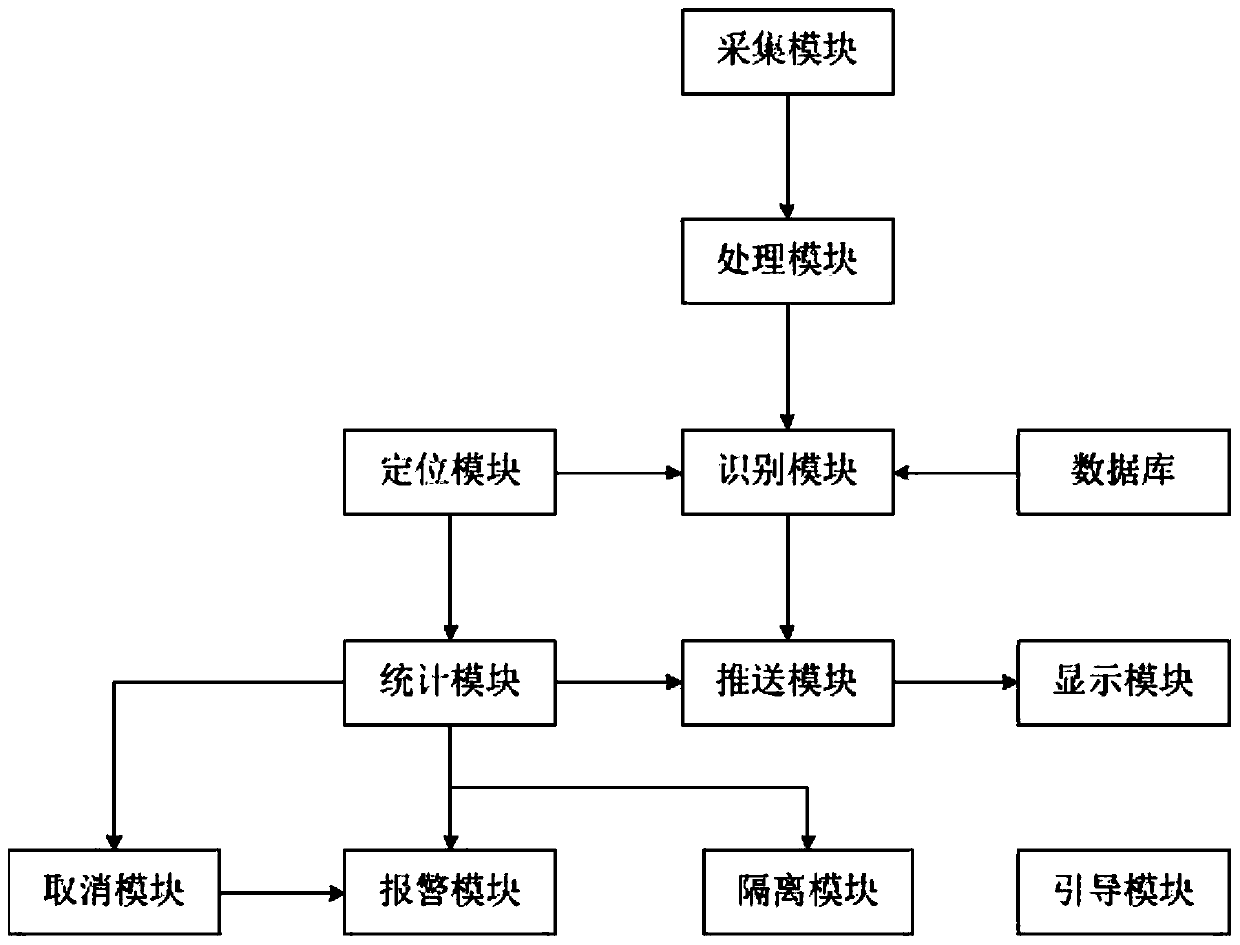

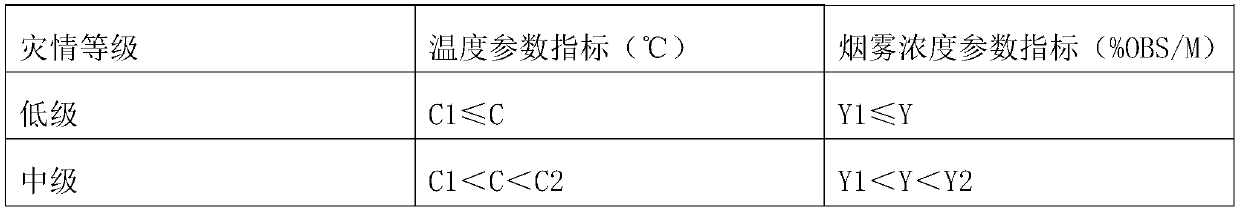

Firefighting real-time monitoring system

InactiveCN110176119ATimely controlAvoid the occurrence of safety accidentsFire alarmsPanicFire - disasters

The invention relates to the field of firefighting monitoring in construction and provides a firefighting real-time monitoring system. In existing fire disaster monitoring system, direct broadcastingof the fire disaster may cause panic and crowding, resulting in safety accidents. The invention solves the above problem. The firefighting real-time monitoring system comprises a collection module forcollecting environment parameters, and a processing module processing collected environment parameters and generating environment information, and further comprises a database storing a disaster situation level table comprising disaster condition information of different levels, a recognition module for recognizing disaster condition information, a positioning module for positioning a struck areaand obtaining positioning information, a statistics module for calculating stream of people of each area in real time and generating real-time stream of people information, and a pushing module for pushing the disaster condition information to a corresponding pushing object.

Owner:CHONGQING UNIV OF ARTS & SCI

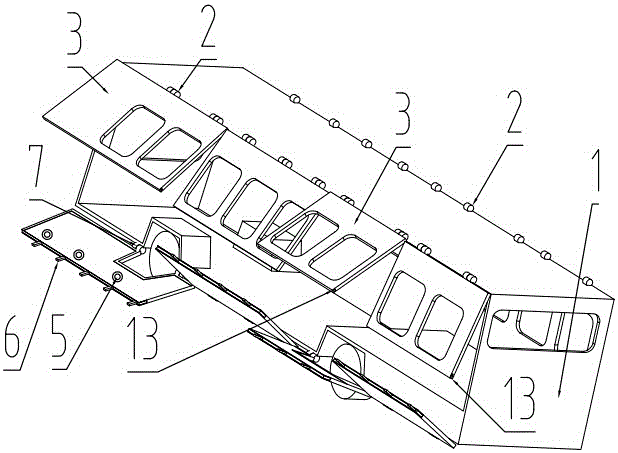

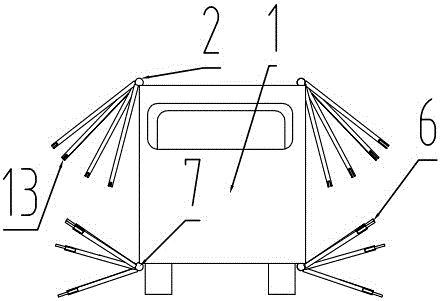

Novel urban bus body

InactiveCN105035189ASimple designEasy to openPedestrian/occupant safety arrangementSuperstructure subunitsTraffic accidentEngineering

The invention discloses a novel urban bus body, belongs to the technical field of traffic safety, and relates to an urban public transport means. The bus body is mainly used for solving the problems that when a fire or a traffic accident happens to an urban bus, passenger escape is difficult, and injuries and deaths are large. Walls on the left side and the right side of the bus body are designed into a plurality of paired side wall blocks, the upper side wall blocks and the lower side wall blocks are combined together through side wall locks, all the side wall blocks are combined, and therefore closed space is formed in the bus body. When an accident happens suddenly, rotary knobs are rotated, the corresponding paired upper side wall blocks and lower side wall blocks can be unlocked and opened, and passengers can fast leave the bus in accident. The novel urban bus body is simple in structure and flexible in operation, a pure mechanical structure is adopted, and therefore high reliability is achieved. After the paired upper side wall block and lower side wall blocks are opened, the passengers can escape conveniently, the phenomena of congestion and the like can be avoided, and casualties are reduced.

Owner:UNIV OF JINAN

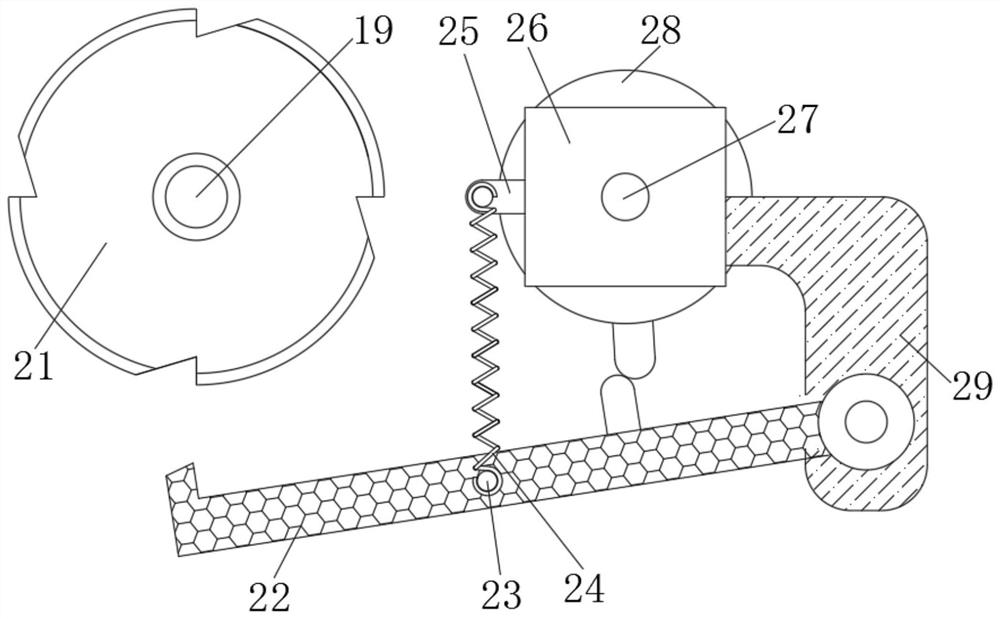

Adjusting mechanism for commodity packaging conveying belt

InactiveCN112278406ANot easy to damageQuality is not affectedConveyorsPackagingStructural engineeringE-commerce

The invention relates to the technical field of electronic commerce, and discloses an adjusting mechanism for a commodity packaging conveying belt. Supporting rods are included, a baffle is connectedto the upper sides of the supporting rods, a first rotating wheel is connected to the outer side of a first rotating shaft, and a rotating rod is connected to the outer side of the first rotating shaft and the front side of the first rotating wheel. A third moving rod is clamped and connected to the lower side of the first rotating wheel, and a first cylindrical block is connected to the front side of the third moving rod. According to the adjusting mechanism for the commodity packaging conveying belt, the rotating rod is pushed by commodities to rotate so that the commodities can be conveyedrightwards, and after a convex rod on a first rotating disc passes through a convex rod on the third moving rod, third moving rod is reset inwards under the action of a second spring and is connectedwith the first rotating wheel in a clamped mode again, and the rotating rod limits transportation of the commodities again. The operation is repeated, so that the distance between every two commodities is controlled, and the effects that the commodities are not crowded and the packaging operation is simple are achieved through the structure.

Owner:广州正宏电子商务有限公司

Fluid type stepless locking rope spring self-adaptation robot finger device

The invention discloses a fluid type stepless locking rope spring self-adaptation robot finger device and belongs to the technical field of robots hands. The fluid type stepless locking rope spring self-adaptation robot finger device comprises a driver, multiple finger sections, multiple joint shafts, multiple joint spring pieces, a transmission mechanism, a tendon rope, a rope pulling piece, a fluid pipeline, a fluid drainable piece, multiple pistons, multiple friction blocks and fluid. The fluid type stepless locking rope spring self-adaptation robot finger device can be used for comprehensively achieving the function of self-adaptation grabbing and continuous synchronous locking of multiple joints. The device is used for grabbing objects and can automatically adapt to the shapes and the sizes of the objects through the joint spring pieces, and the grabbing process is fast and stable; a joint locking manner is adopted after the objects are grabbed, fingers are prevented from rebounding to lose stability, and larger grabbing force is provided; the joint angles which can be locked are continuous, and the multiple joints can be locked synchronously; and the device is simple in structure, easy to control and low in design and manufacturing cost.

Owner:TSINGHUA UNIV

Cam synchronous locking elastic self-adaptation robot finger device

InactiveCN105798934APrevent rebound instabilityRebound instability will not occurGripping headsRobot handEngineering

The invention discloses a cam synchronous locking elastic self-adaptation robot finger device and belongs to the technical field of robot hands. The cam synchronous locking elastic self-adaptation robot finger device comprises a motor, multiple finger sections, multiple joint shafts, multiple spring pieces, a tendon rope, a three-dimensional cam mechanism, a wheel type transmission mechanism and the like. By means of the device, the motor, the tendon rope, the spring pieces, the three-dimensional cam mechanism and the like are used for comprehensively achieving the function of self-adaptation passive grabbing and continuous synchronous locking of the multiple joints. The device is used for grabbing objects and can automatically adapt to the shapes and the sizes of the objects; a joint locking manner can be adopted after the objects are grabbed, the grabbing process is fast and stable, the joints are locked after grabbing, the fingers are prevented from rebounding to lose stability, and larger grabbing force can be provided; the multiple joints can be locked synchronously; joint angles capable of being locked are continuous; and the device is simple in structure, small in size, light, easy to control and low in design and manufacturing cost.

Owner:TSINGHUA UNIV

Tendon rope lateral locking linkage adaptive robot finger device

Tendon-rope lateral locking linkage adaptive robot finger device, belonging to the field of robot hand technology, including motor, reducer, transmission mechanism, main tendon rope, N finger segments, N-1 joint shafts, N-1 joint springs pieces, N-1 articulated wheels, the first pull cord, N-1 joint sliders, N-1 friction blocks, N-1 locking tendons, N-1 locking springs and the second pull cord , where N is a natural number greater than 1. The device is used for grabbing objects, and realizes the functions of self-adaptive grabbing and continuous synchronous locking of multiple joints; the grabbing process is fast and stable, and the joints are locked after grabbing to prevent fingers from rebounding and unstable, and can provide a larger grip force; multiple joints can be locked synchronously; the lockable joint angle is continuous; the device has simple structure, small size, light weight, easy control, and low cost in design, manufacture, assembly and maintenance.

Owner:TSINGHUA UNIV

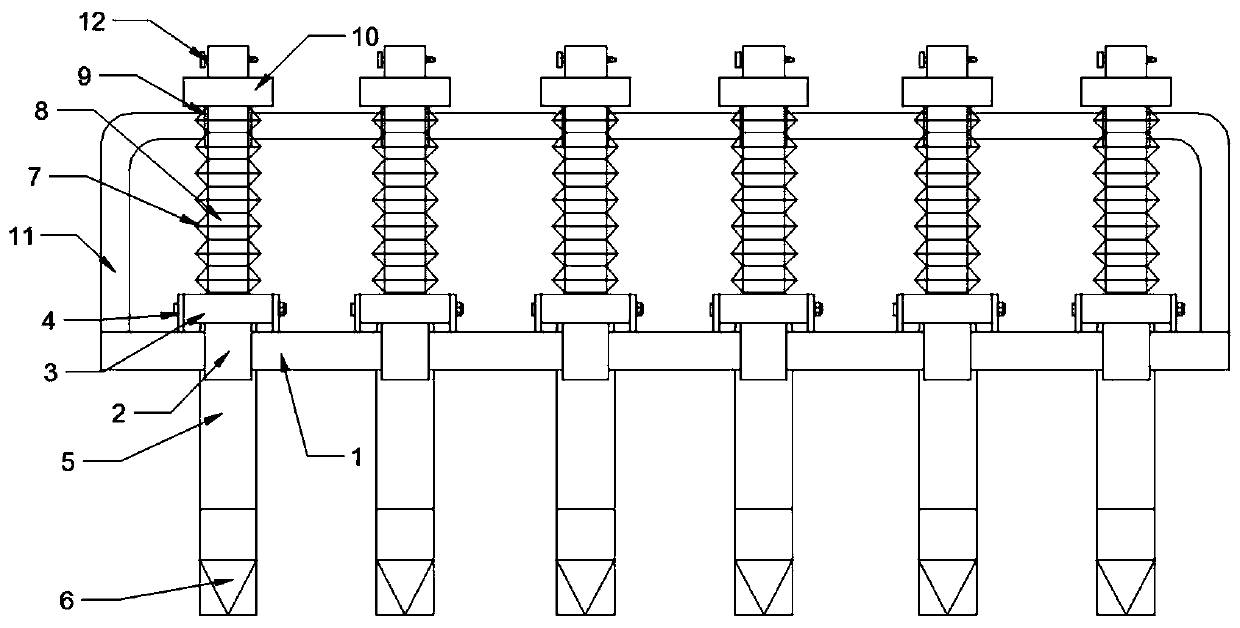

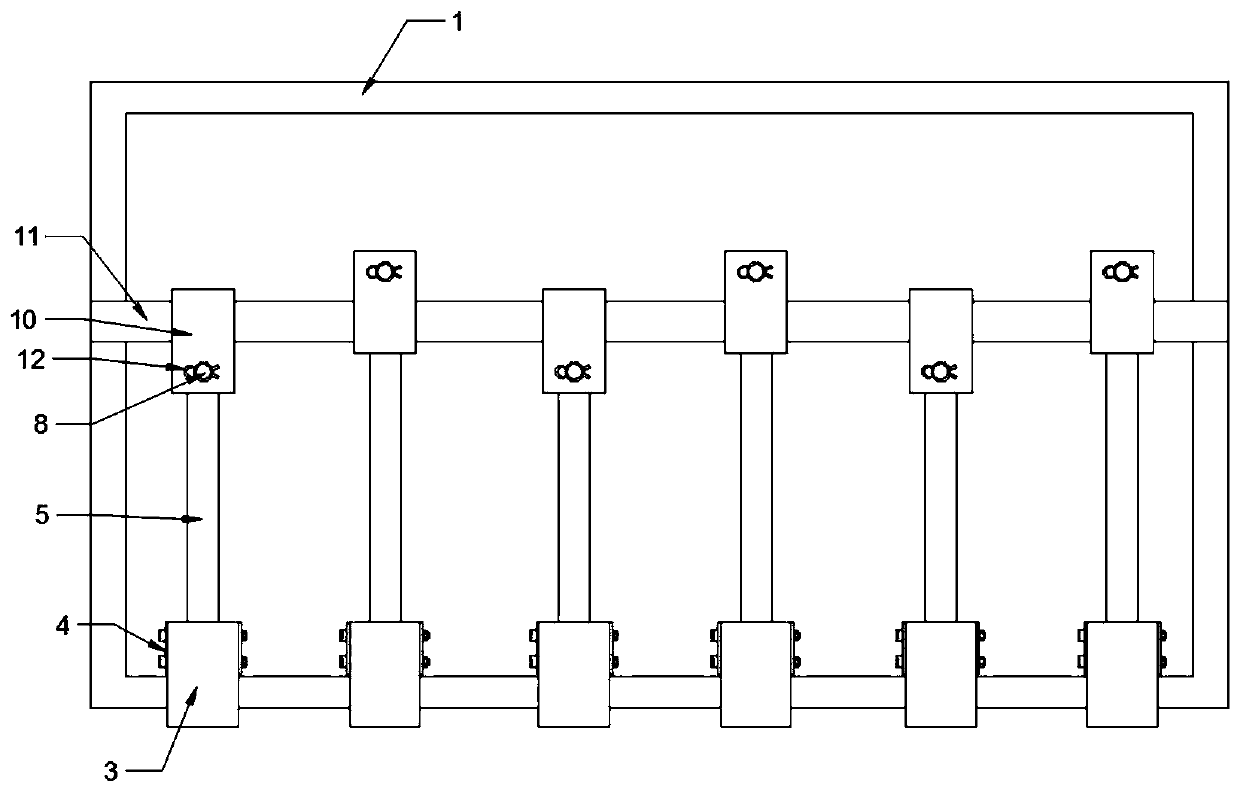

Ditcher for profiling seeder and using method of ditcher

InactiveCN110809947ANot easy to tangleAchieve weed control effectPlantingFurrow making/coveringSeederAgricultural engineering

The invention discloses a ditcher for a profiling seeder and a using method of the ditcher, and belongs to the technical field of agricultural mechanical equipment. The ditcher comprises a lower frameand an upper frame arranged at the upper end of the lower frame, wherein a plurality of first fixing blocks are fixedly connected to a front end beam of the lower frame through a plurality of first connecting blocks, U-shaped plates are connected to the outer side of the rear ends of the first fixing blocks, a plurality of second fixing blocks are fixedly connected to the upper end of the upper frame through a plurality of second connecting blocks, movable pipes are arranged on a plurality of the second fixing blocks in a penetrating manner, the outer sides of the movable pipes are sleeved with springs, ditching pipes, which are in movable connection with the U-shaped plates through second rotary shafts, are connected to the lower ends of the movable pipes in a movable manner, and side blades are fixedly arranged on both sides of the lower positive axis of each the ditching pipe. Through the ditching pipes with hook-shaped round pipe structures provided with the side blades, the winding of weeds is reduced, and thus the weeding effect is achieved; and the matching use of the movable pipes and the springs can enable the ditcher to be used in uneven land, and thus the ditching speedand effect are guaranteed.

Owner:宿州市信德机械股份有限公司

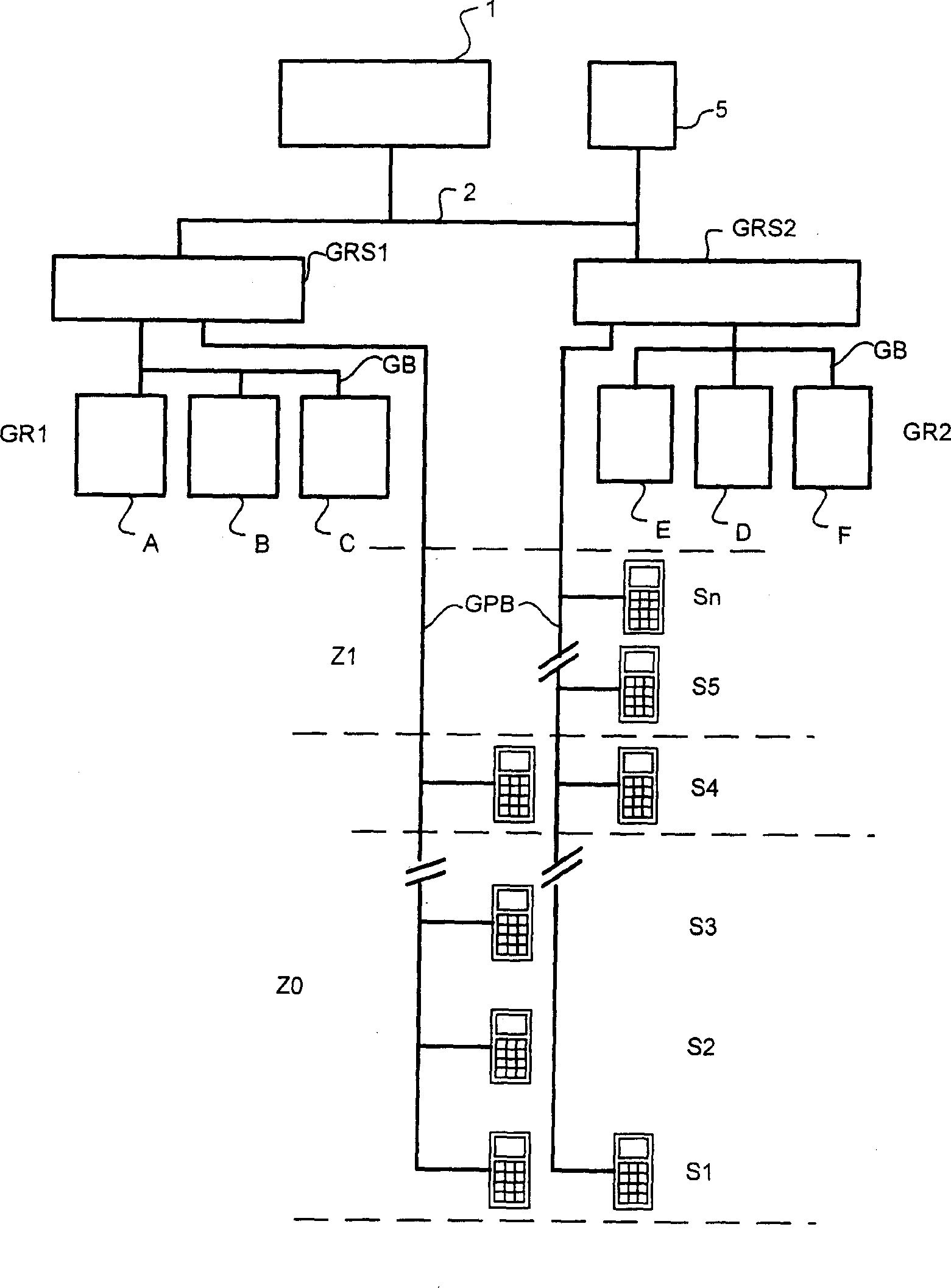

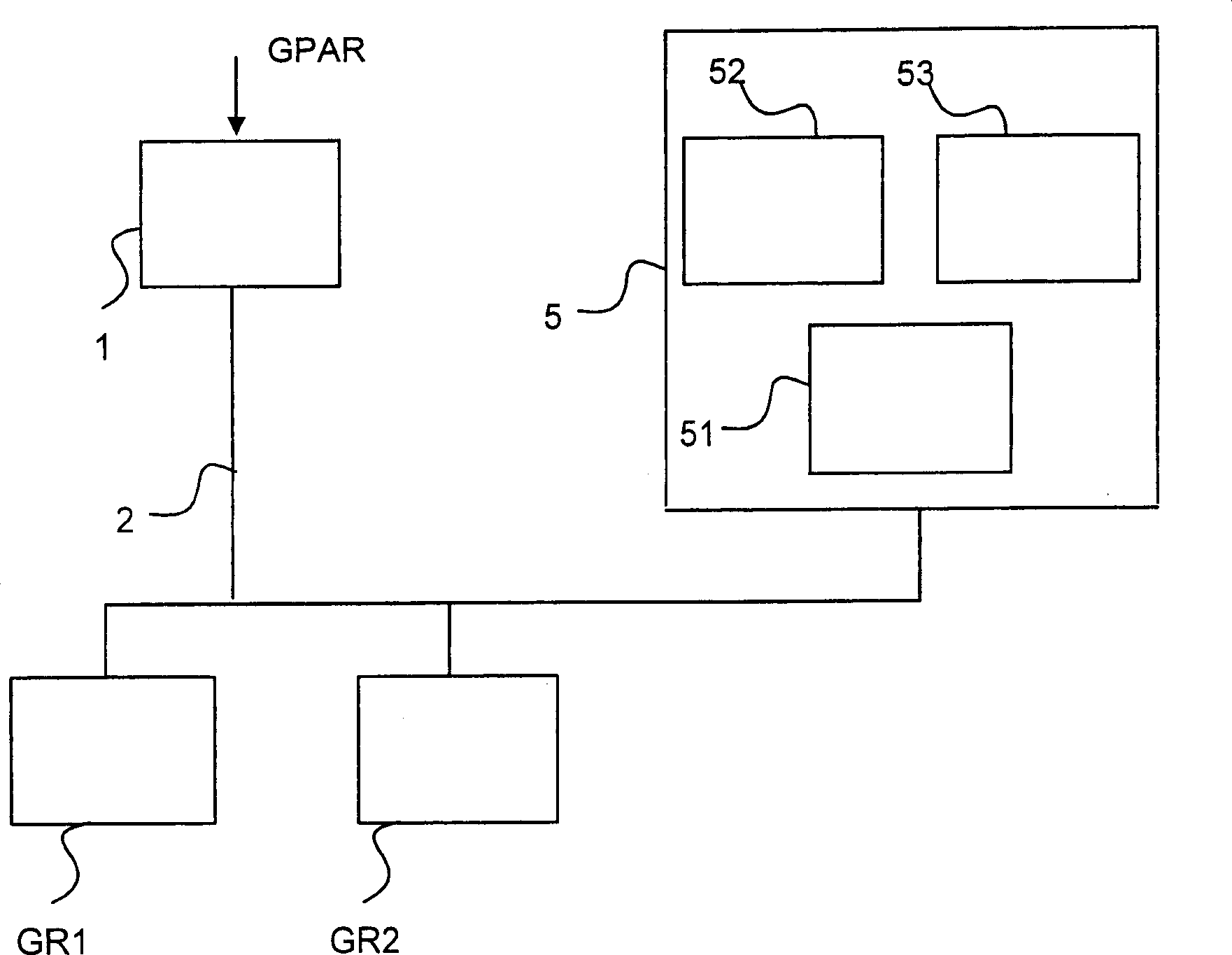

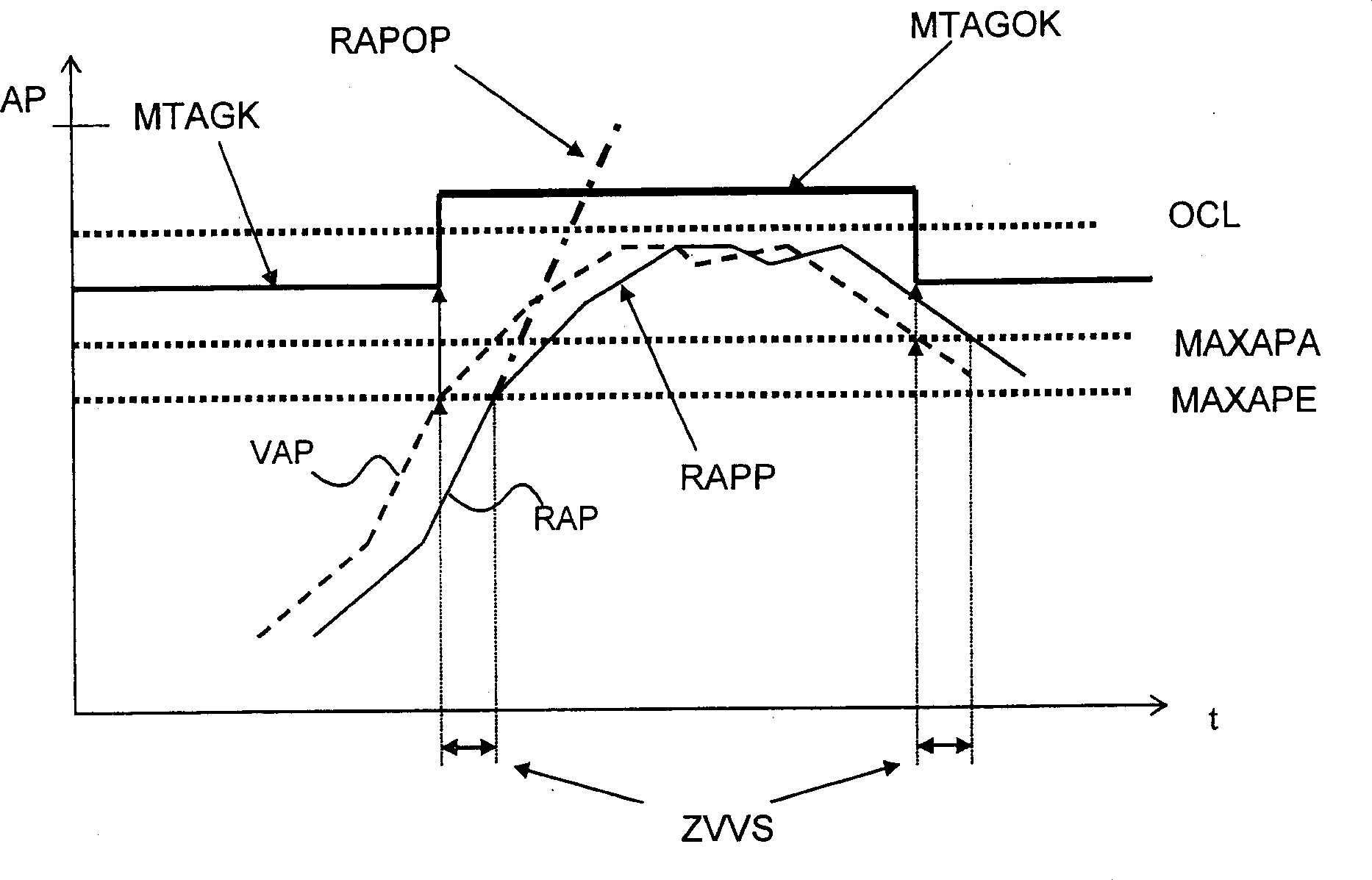

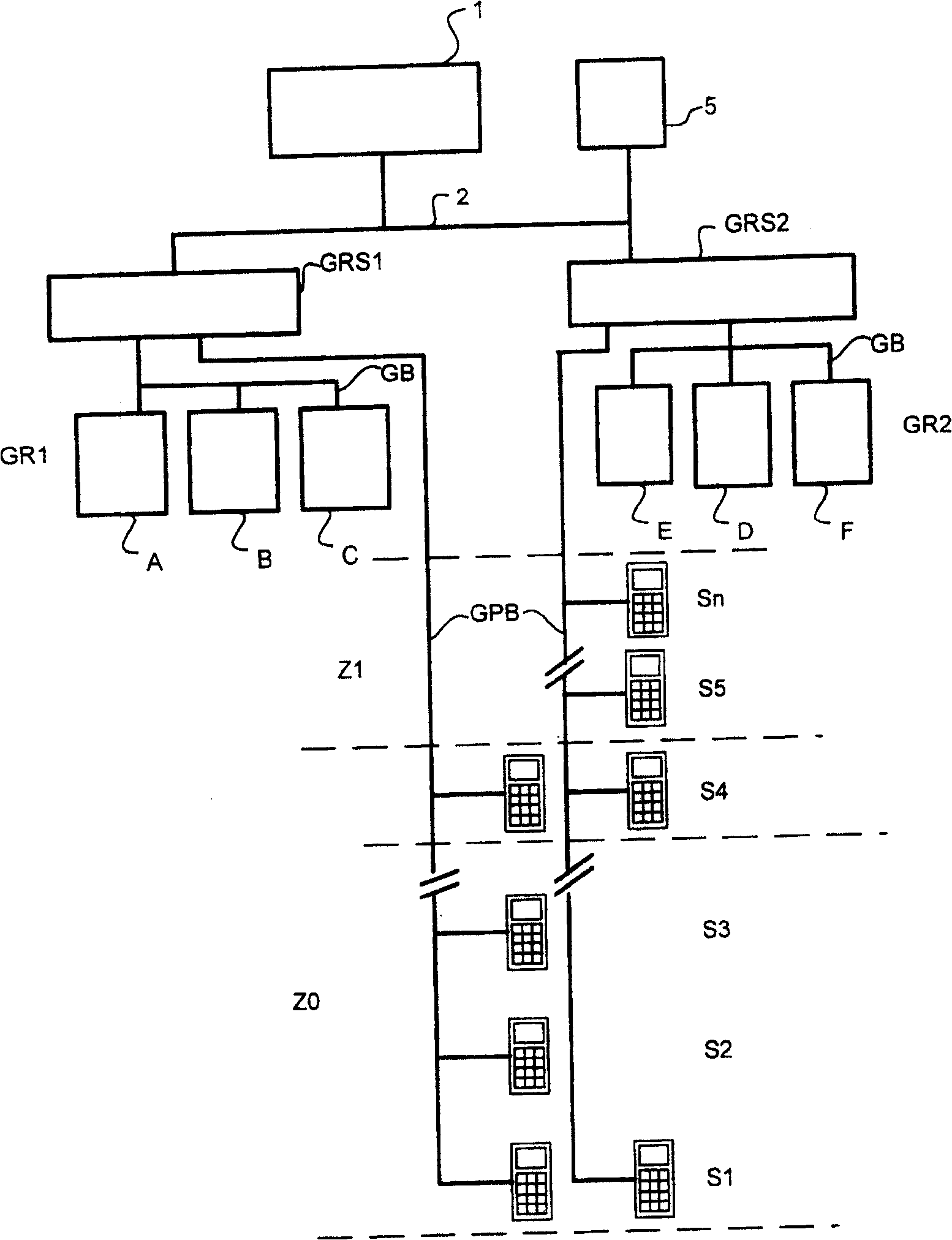

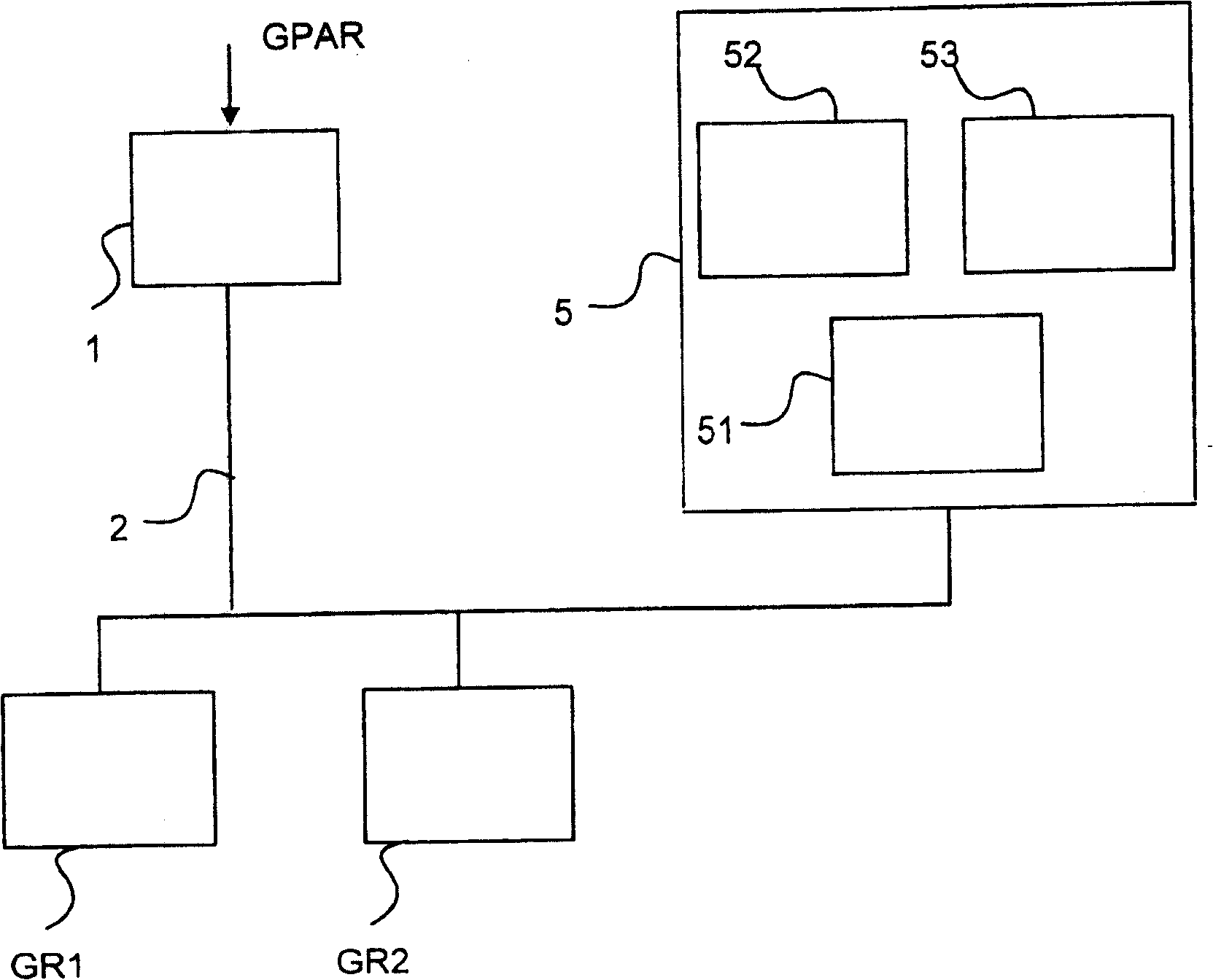

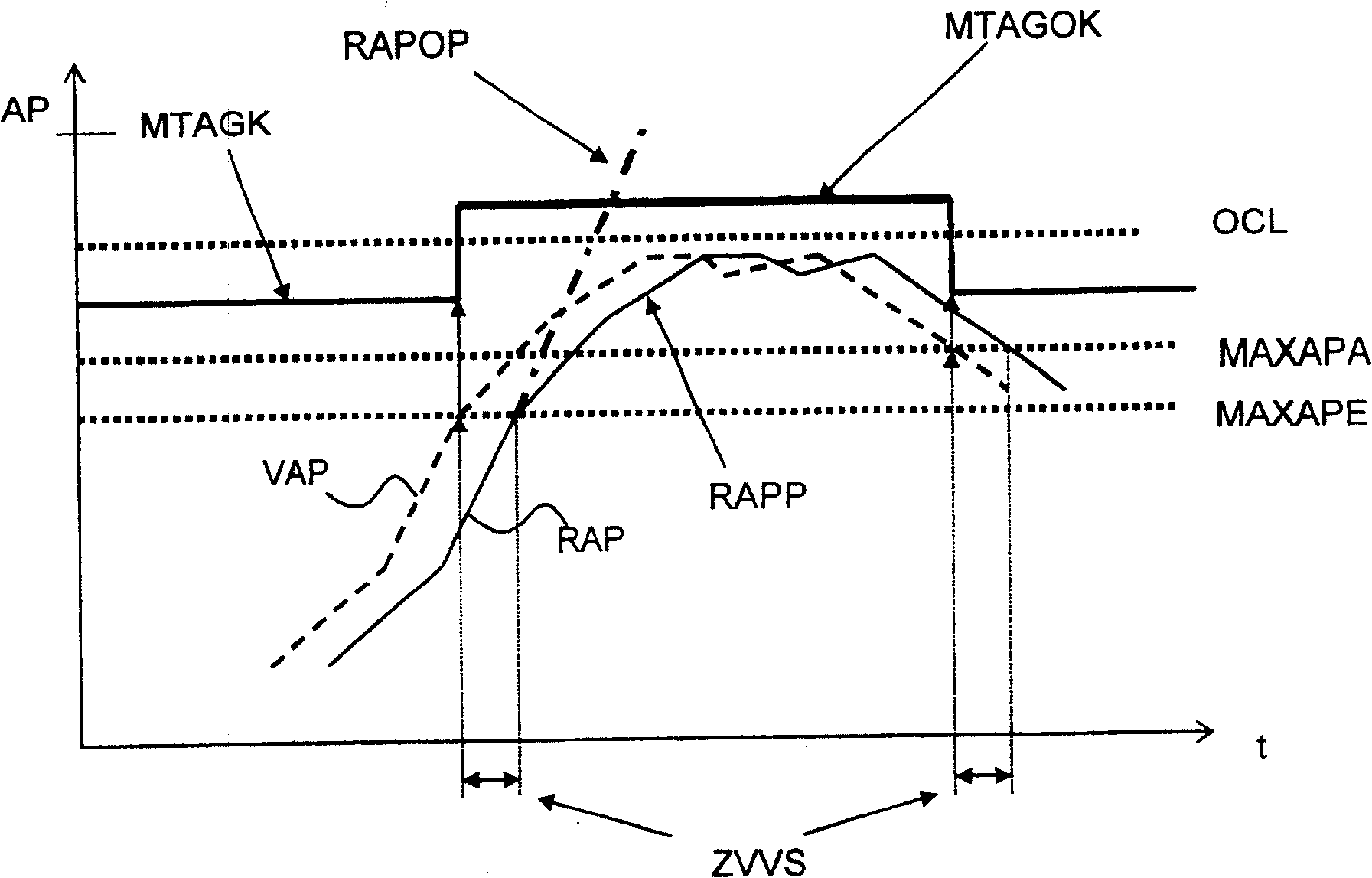

Method and apparatus for controlling zone operating of elevator equipment

A method for controlling a zonally operated elevator installation, wherein on a changeover floor changing between zones is made possible, and wherein with a delivering elevator group and a collecting elevator group transportation to and from the changeover floor is realized, and wherein a trip destination is entered via a destination-call control by each passenger to be transported. An elevator installation for zonal operation in buildings with several elevators, wherein each elevator group contains at least one destination-call input device for registering the destination of a passenger. Each elevator is assigned to an elevator group, the building is divided into zones, and a changeover floor for changing between the elevator groups is arranged between the zones. The delivering elevator group and the collecting elevator group are combined into a multi-group which is controlled by a multi-group control.

Owner:INVENTIO AG

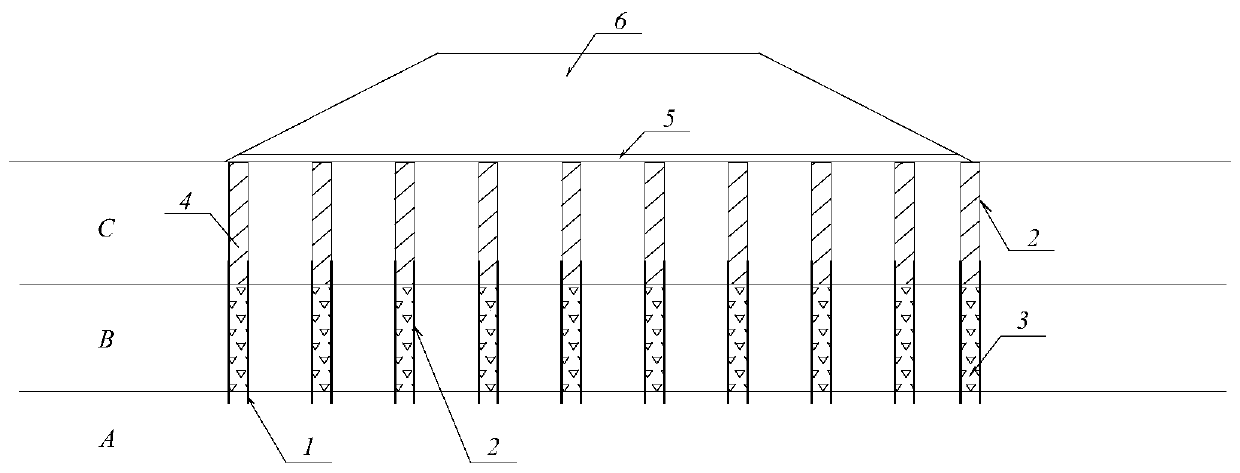

Construction method of foundation reinforcement structure of soft soil overlaying construction waste dump

InactiveCN110344393AEnsure effective implementationEasy constructionSoil preservationRebarSoil horizon

Disclosed is a construction method of a foundation reinforcement structure of a soft soil overlaying construction waste dump to ensure construction quality of reinforcement piles and reinforcement foundations and enable the foundation reinforcement structure of the soft soil overlaying construction waste dump to be effectively implemented. The structure is constructed according to the following steps: carrying out column hammer punching on a foundation to the top of a foundation soft soil layer by using a column hammer machine; inserting vertical steel bars into the foundation soft soil layerat intervals on the circumference of column hammer holes; mixing a concrete mixed material; placing deep and long gunny bags from ground to the column hammer holes with the bottom parts being placed on the top surface of the foundation soft soil layer; filling the deep and long gunny bags with the concrete mixed material in layers, and carrying out light tamping in layers by using the column hammer until the concrete mixed material is pressed into the bottom of the soft soil foundation under the restriction of the deep and long gunny bags; filling the deep and long gunny bags with an upper tamping filler in layers, and tamping the filler by using a low-energy column hammer; filling the deep and long gunny bags with the upper tamping filler in layers, and increasing column hammer tamping energy level by level in layers until to the design height of the surface of the foundation; and laying a cushion layer on the reinforcement foundation, and constructing filling work in layers.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Intelligent electric rail car traffic network system

ActiveCN101332820BPrecise speed controlAvoid traffic accidentsRailway componentsRailway stationTraffic networkTraffic congestion

Owner:陈笠

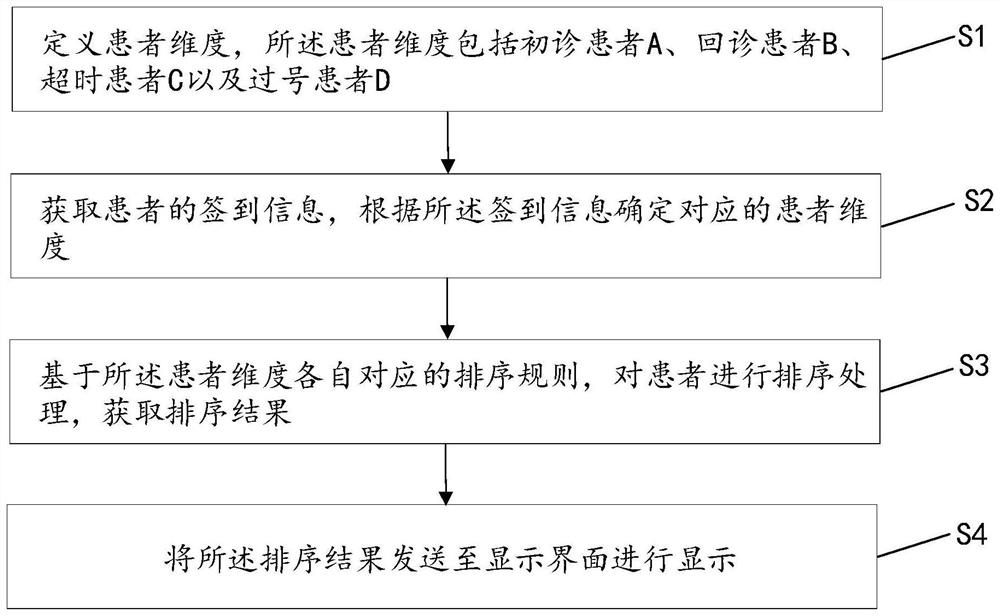

Intelligent triage sorting method

PendingCN112669945AWait in line fair and justRelieve the stress of mediationHealthcare resources and facilitiesTriagePatient dimensions

The invention relates to the technical field of outpatient service numbering, and discloses an intelligent triage sorting method. The method comprises the following steps: defining patient dimensions including an initial diagnosis patient A, a back diagnosis patient B, an overtime patient C and an over-numbered patient D; acquiring sign-in information of a patient, and determining a corresponding patient dimension according to the sign-in information; based on the sorting rules corresponding to the patient dimensions, sorting the patients to obtain a sorting result; and sending the sorting result to a display interface for display. Corresponding sorting rules are adopted for different patients, fair sorting is given to the patients, queuing and waiting of the patients become more fair, and queuing disputes are avoided; a patient can check the queuing condition in real time through the held mobile terminal, so that the patient does not need to wait outside a consulting room all the time, and the waiting time is saved; and prompt information is sent to the patients who sign in in advance to prompt the patients to sign in within the specified time, so that personnel distribution in hospitals is facilitated.

Owner:四川乐恩乐达信息技术有限公司

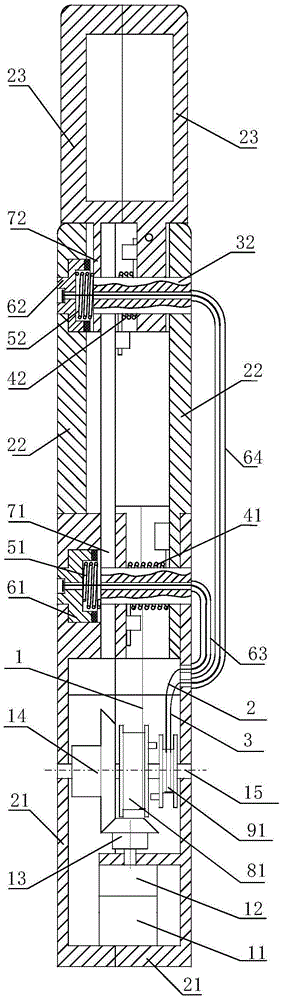

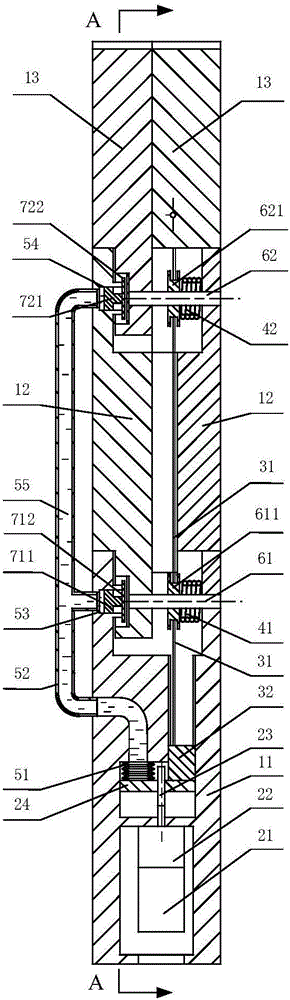

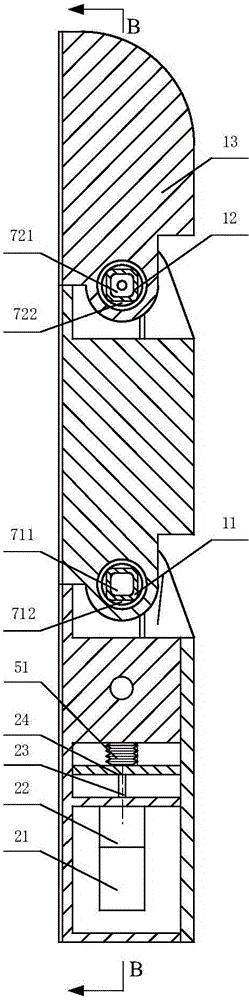

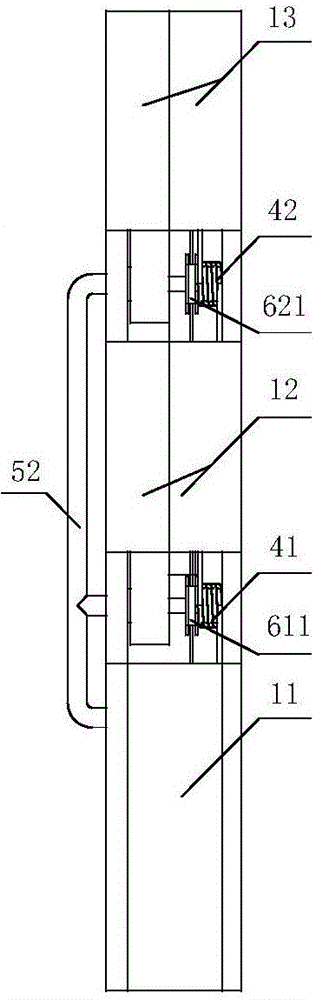

patient transfer bed

The invention discloses a patient ferry bed which comprises a vehicle body, wherein the vehicle body is provided with a lifting mechanism and universal casters. The ferry bed that can move horizontally is installed on the vehicle body. The ferry bed comprises a bed board mechanism, a bed head and a bed tail beam mechanism. The patient ferry bed is of a single-layer mobile bed board structure and is simple in structure, needed parts are less, and the patient ferry bed is low in production cost and failure rate and convenient to maintain; the friction force caused by the single-layer mobile bed board structure is very small, a belt does not generate kinetic friction with the bed surface and the body of a patient, a bed sheet cannot be wound up, the safe transfer of the patient is achieved, and secondary injury is avoided; operators almost do not need to be in contact with the patient in the process, and the propagation of infecting bacteria is effectively avoided.

Owner:TIANJIN QIRUITONG TECH CO LTD

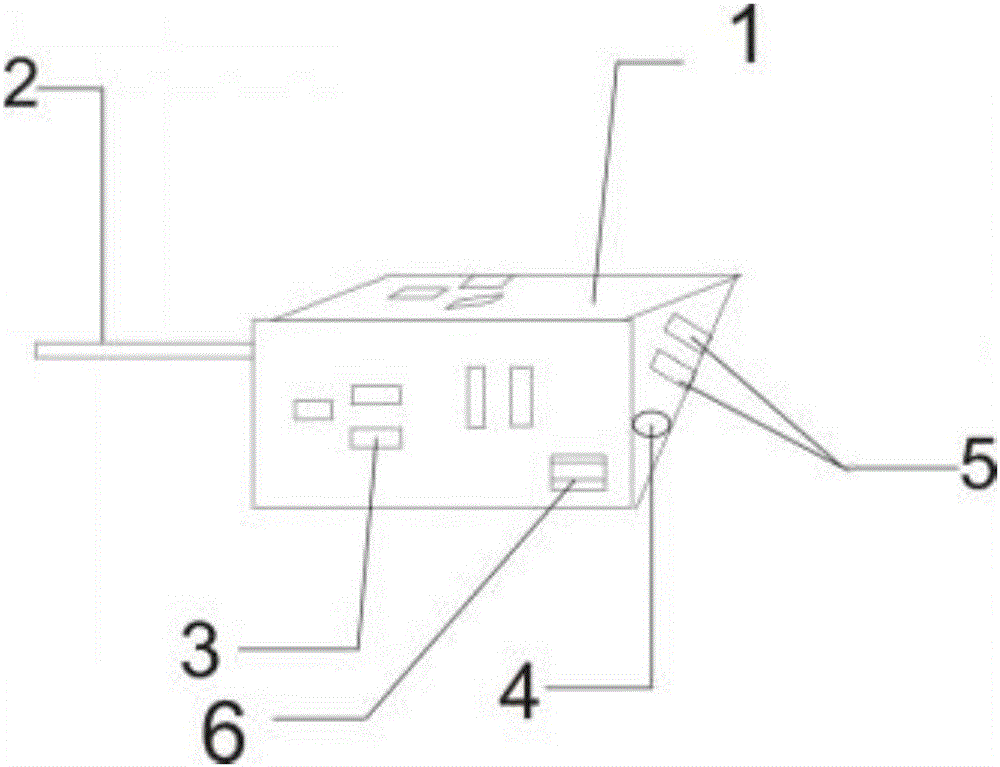

Energy-saving wiring board

InactiveCN105449430AEasy to use at the same timeEasy to organizeCouplings bases/casesFlexible lead accommodationControl powerEngineering

The invention provides an energy-saving wiring board. The energy-saving wiring board comprises a C-shaped wiring board body; the C-shaped wiring board body is connected with a plug through a power line; multiple jacks are uniformly formed in the C-shaped wiring board body; the jacks comprise two-hole jacks and three-hole jacks that can be shared; the multiple jacks face to different directions; each jack is provided with a switch for independently controlling power on and power off; the C-shaped wiring board body is provided with an electric quantity display screen; an electric quantity counter is arranged in the C-shaped wiring board body; an electric quantity reset button is arranged on the side face of the C-shaped wiring board body; and the C-shaped wiring board body is provided with a power supply indicator lamp. The energy-saving wiring board provided by the invention is simple in structure, convenient to use and high in space utilization rate; and meanwhile, the jacks are formed at large intervals, so that the energy-saving wiring board is high practicability and multifunctional.

Owner:TIANJIN KUNRI TECH DEV

Novel power strip

InactiveCN106785608AEfficient use ofNo crowdingCouplings bases/casesTwo-part coupling devicesComputer moduleTransfer switch

The invention provides a novel power strip and relates to the field of electrical equipment. The novel power strip comprises a prism-shaped casing, wherein a plurality of jacks are formed in the casing, jack iron pieces are also arranged in the casing, a plurality of three-hole jacks and / or two-hole jacks are formed in one side surface of the casing, a power line is arranged at the lower end of the casing, a power switch and indicator lights are arranged at the top end, a USB charging port is also formed in one side surface of the casing, a transformation module is also arranged in the casing, and the USB charging port is conducted with the power line through the transformation module.

Owner:GUANGXI UNIV FOR NATITIES

Process for producing microconfiguration transfer sheet and apparatus therefor

A process for producing a sheet and apparatus therefor that in the operation of heating a sheet substratum and a metal mold with fine uneven configuration, bringing them into mutual contact and pressuA process for producing a sheet and apparatus therefor that in the operation of heating a sheet substratum and a metal mold with fine uneven configuration, bringing them into mutual contact and pressurizing the same so as to form the fine uneven configuration on a surface of the sheet substratum, avoid transfer failure attributed to air trapping at the transfer face between the metal mold and therizing the same so as to form the fine uneven configuration on a surface of the sheet substratum, avoid transfer failure attributed to air trapping at the transfer face between the metal mold and thesheet substratum to thereby obtain a sheet having the desired fine uneven configuration formed on its surface. There are provided a process for producing a microconfiguration transfer sheet, and apparsheet substratum to thereby obtain a sheet having the desired fine uneven configuration formed on its surface. There are provided a process for producing a microconfiguration transfer sheet, and apparatus therefor, comprising, in the microconfiguration transfer sheet producing operation including heating a sheet substratum and a metal mold with fine uneven configuration, bringing them into mutualatus therefor, comprising, in the microconfiguration transfer sheet producing operation including heating a sheet substratum and a metal mold with fine uneven configuration, bringing them into mutualcontact and pressurizing the same so as to form the fine uneven configuration on a surface of the sheet substratum, carrying out the configuration formation while changing the planarity of a configuracontact and pressurizing the same so as to form the fine uneven configuration on a surface of the sheet substratum, carrying out the configuration formation while changing the planarity of a configuration forming face consisting of at least one, or a combination, of a pair of pressurization plates or metal molds arranged so as to apply pressure to the sheet substratum and the metal mold.tion forming face consisting of at least one, or a combination, of a pair of pressurization plates or metal molds arranged so as to apply pressure to the sheet substratum and the metal mold.

Owner:TORAY IND INC

Rack type variable grip elastic linkage adaptive robot finger device

InactiveCN105773647BPrevent rebound instabilityRebound instability will not occurGripping headsRobot handEngineering

The invention discloses a rack-type elastic-linkage self-adaptive robot finger device with variable-grabbing force, and belongs to the technical field of robot hands. The rack-type variable grabbing power elastic linked self-adaptive robot finger device comprises a motor, a plurality of finger sections, a plurality of joint shafts, transmission mechanisms, a plurality of transition shafts, a plurality of joint spring parts, a plurality of pulleys, a plurality of driving levers, a plurality of driving plates, a plurality of gear parts, a rope winding wheel, and a tendon rope. According to the device, the functions of self-adaptive grabbing and continuous locking of a plurality of joints are comprehensively achieved through utilizing the motor, the transmission mechanisms, driven driving plates, the driving levers, a first gear, a second gear, a rack, the rope winding wheel, the tendon rope and the spring parts; the device is used for grabbing objects, and can automatically adapt to the shapes and sizes of the objects; after object grabbing, a joint locking manner or a non-locking manner can be adopted; the grabbing process is quick and stable, after grabbing, the joints are locked to prevent the finger from bounding back and becoming unstable, and relatively large grabbing force can be provided; lockable joint angles are continuous; and the device is simple in structure, small in volume, light in weight, easy to control, and low in manufacturing and maintenance cost.

Owner:TSINGHUA UNIV

Rack-type multi-joint synchronous locking adaptive robot finger device

The invention discloses a rack type multi-joint synchronous locking self-adaptation robot finger device and belongs to the technical field of robot hands. The rack type multi-joint synchronous locking self-adaptation robot finger device comprises a motor, multiple finger sections, multiple joint shafts, multiple spring pieces, a tendon rope, a rope pulling piece, multiple joint wheels, multiple sets of gear and rack mechanisms and multiple sets of wheel type transmission mechanisms. By means of the device, the motor, the tendon rope, the spring pieces, the wheel type transmission mechanisms and the gear and rack transmission mechanisms are used for comprehensively achieving the function of self-adaptation grabbing and continuous synchronous locking of multiple joints. The device is used for grabbing objects and can automatically adapt to the shapes and the sizes of the objects; a joint locking manner or a joint non-locking manner can be adopted after the objects are grabbed; the grabbing process is fast and stable, the joints are locked after grabbing is conducted, fingers are prevented from rebounding to lose stability, and larger grabbing force can be provided; the multiple joints can be synchronously locked; joint angles which can be locked are continuous; and the device is simple in structure, small in size, light, easy to control and low in design, manufacturing, assembling and maintaining cost.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com