Axial spiral synchronous locking self-adaptive robot finger device

A robot finger and synchronous locking technology, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve problems such as grasping failure, affecting locking effect, and instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

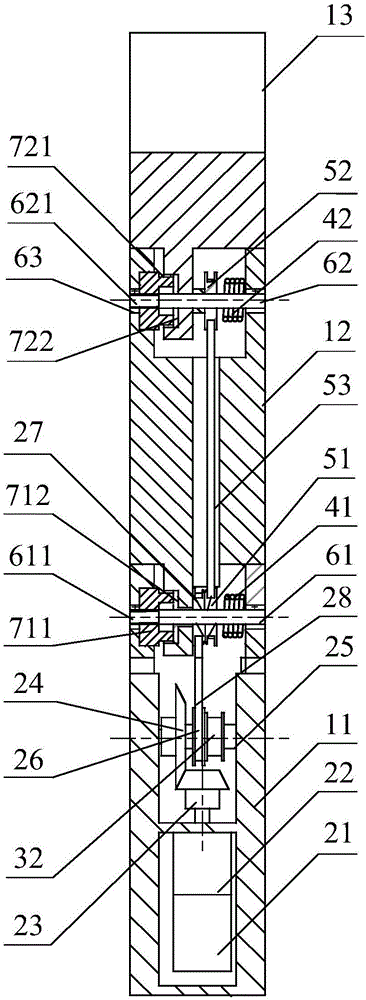

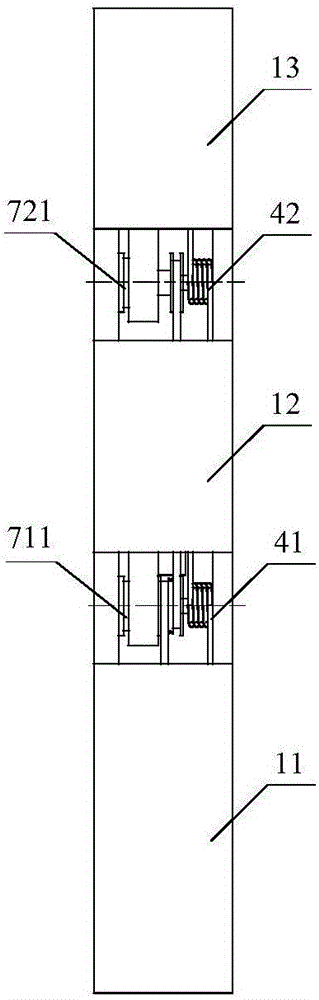

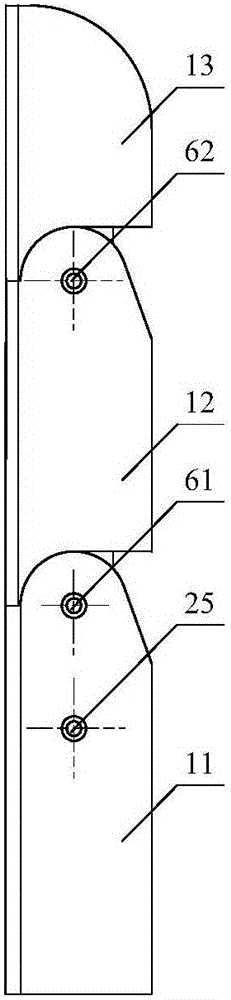

[0043] The specific structure, working principle and working process of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0044]The self-adaptive robot finger device for axial-moving screw synchronous locking provided by the present invention includes a motor, a reducer, a first transmission mechanism, a tendon rope, a rope member, N finger segments, N-1 joint shafts, and N-1 springs parts and N-1 articulated wheels; the motor is fixedly connected to the first finger segment; the output shaft of the motor is connected to the input shaft of the reducer, and the output shaft of the reducer is connected to the input end of the first transmission mechanism Connected, the output end of the first transmission mechanism is connected with the pull cord; the pull cord is slid or rotated and arranged in the first finger section; one end of the tendon rope is connected with the pull cord, and the other end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com