Process for producing microconfiguration transfer sheet and apparatus therefor

A manufacturing method and a manufacturing device technology, which are applied in the field of manufacturing and manufacturing devices for micro-shape transfer sheets, can solve the problems of time-consuming, pressure deviation on the forming surface, and different surface pressure distribution, and achieve the effect of uniform pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0106] (1) Die size: 500mm (film width direction) x 800mm (film moving direction) x 20mm (thickness).

[0107] (2) Mold material: copper.

[0108] (3) Fine shape: a pitch of 50 μm, a convex portion width of 25 μm, a convex portion height of 50 μm, and a rectangular cross-sectional shape viewed from the film moving direction.

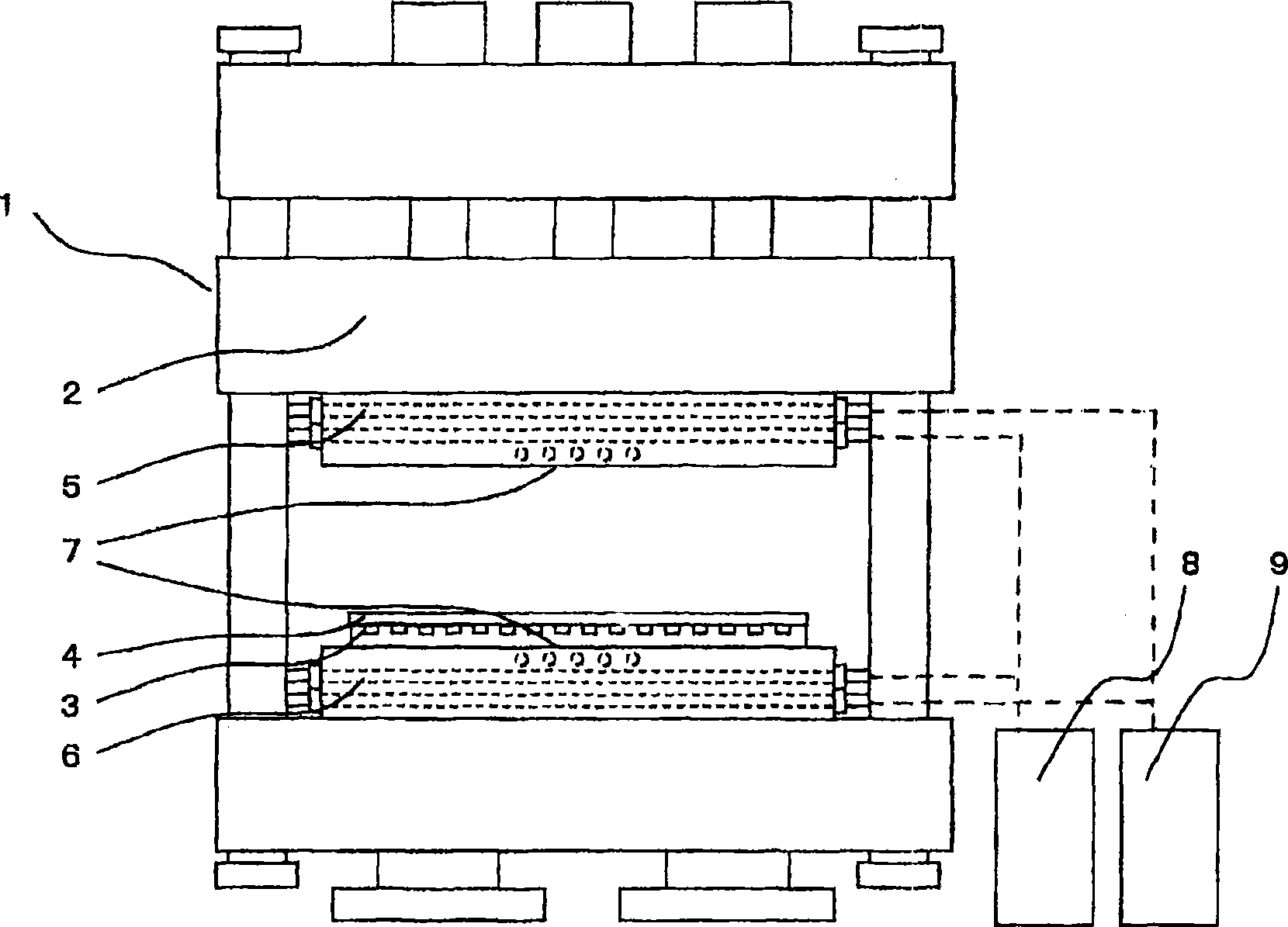

[0109] (4) Pressurization device: the maximum pressurization pressure can reach 3000kN, pressurization is carried out by hydraulic pump.

[0110] (5) Two upper and lower temperature regulating plates made of aluminum alloy with a size of 700 mm (film width direction)×1000 mm (film moving direction) are installed in the pressurizing device, and each is connected to a heating device and a cooling device. The mold is installed on the temperature regulating plate on the lower side. The heating device was a heat medium circulation device, and the heat medium was Baresam #400 (manufactured by Matsumura Petroleum Co., Ltd.), and the heat medium heated to 150°...

Embodiment 2

[0120] (1) Die size: 500mm (film width direction) x 800mm (film moving direction) x 20mm (thickness).

[0121] (2) Mold material: copper.

[0122] (3) Fine shape: a pitch of 50 μm, a convex portion width of 25 μm, a convex portion height of 50 μm, and a rectangular cross-sectional shape viewed from the film moving direction.

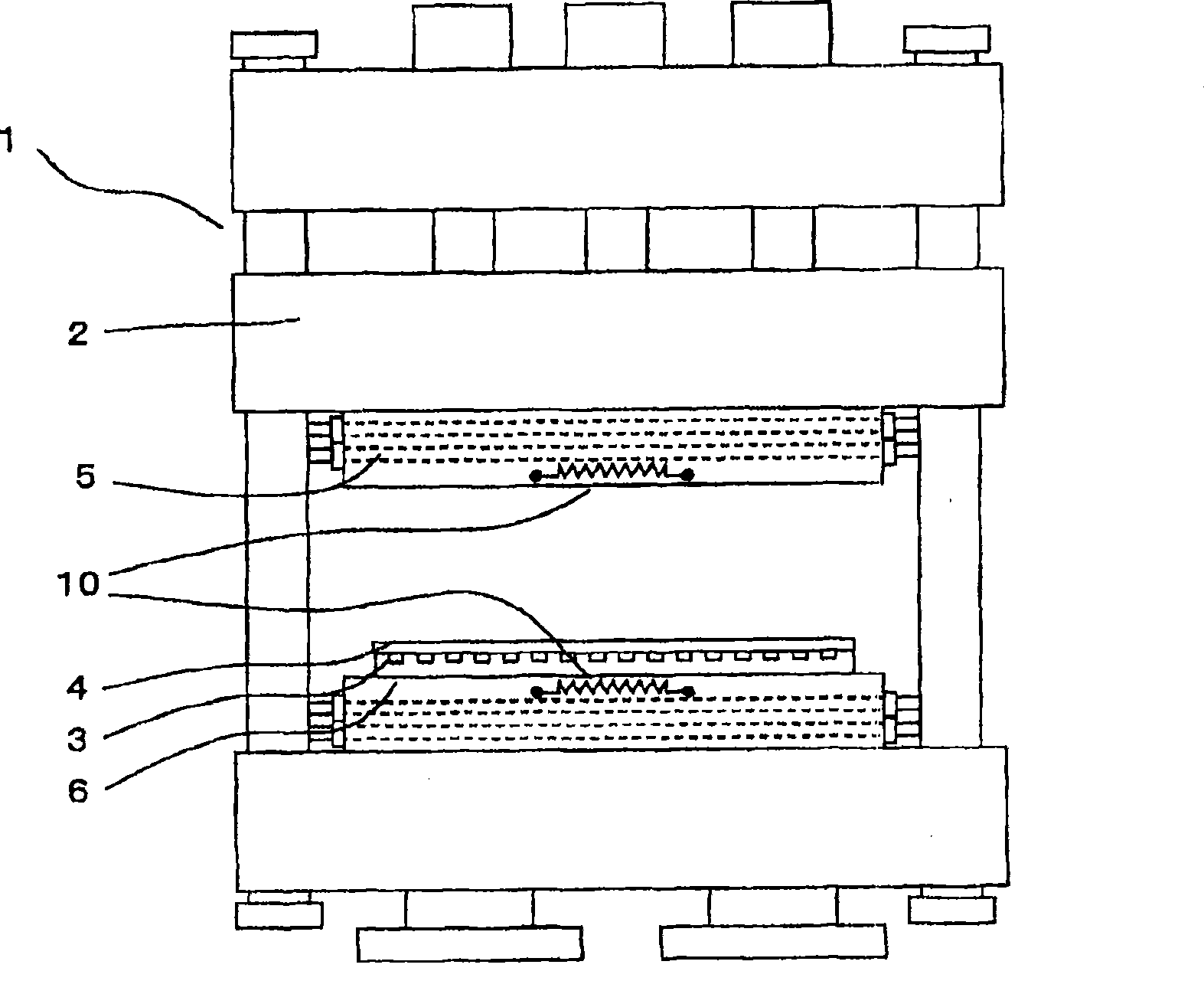

[0123] (4) Pressurization device: the maximum pressurization pressure can reach 3000kN, pressurization is carried out by hydraulic pump.

[0124] (5) Two upper and lower temperature regulating plates made of aluminum alloy with a size of 700 mm (film width direction)×1000 mm (film moving direction) are installed in the pressurizing device, and each is connected to a heating device and a cooling device. The mold is installed on the temperature regulating plate on the lower side. The heating device was a heat medium circulation device, and the heat medium was Baresam #400 (manufactured by Matsumura Petroleum Co., Ltd.), and the heat medium heated to 150°...

Embodiment 3

[0131] (1) Die size: 500mm (film width direction) x 800mm (film moving direction) x 40mm (thickness).

[0132] (2) Mold material: copper.

[0133] (3) Fine shape: a pitch of 50 μm, a convex portion width of 25 μm, a convex portion height of 50 μm, and a rectangular cross-sectional shape viewed from the film moving direction.

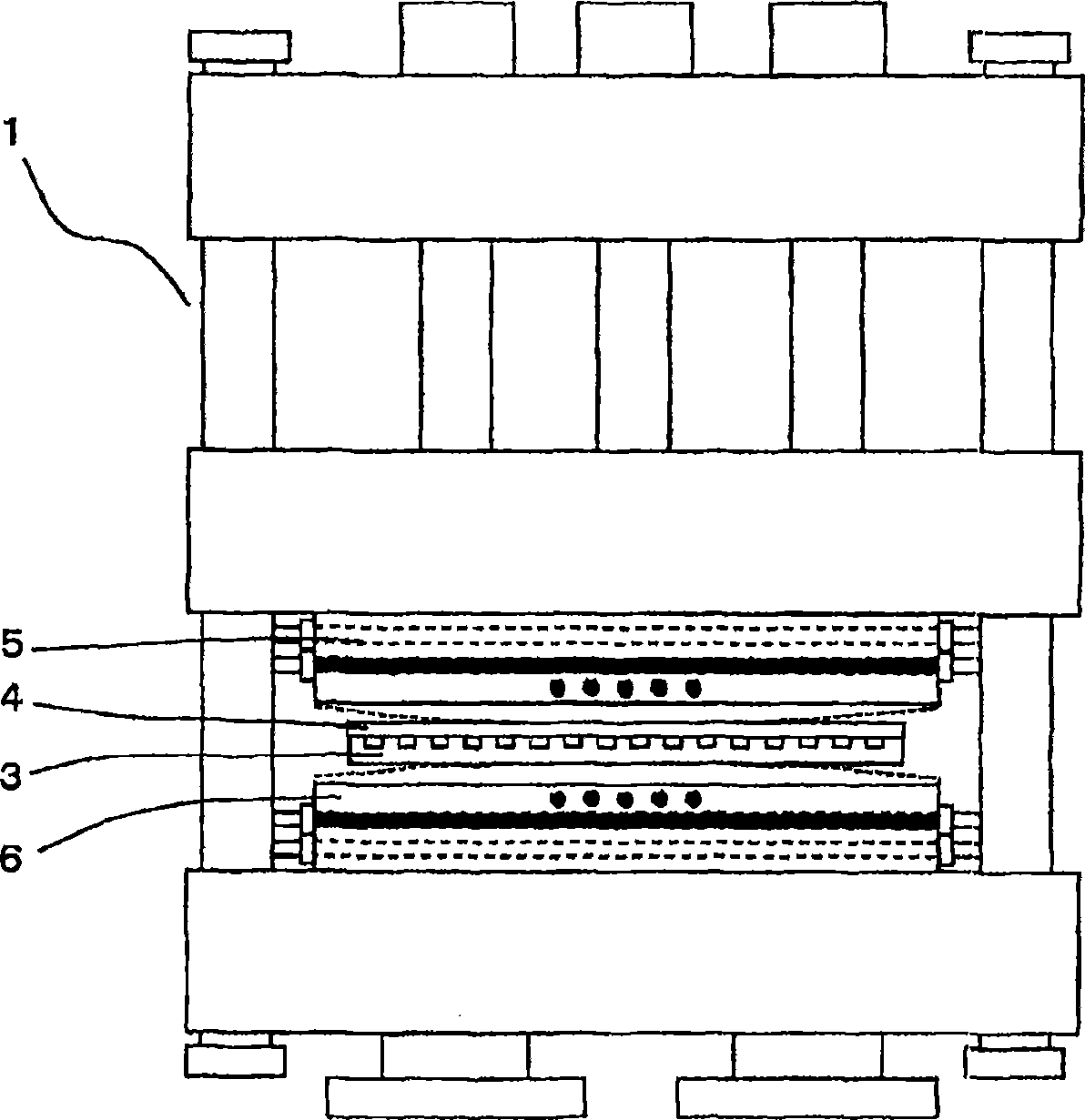

[0134] (4) Pressurization device: the maximum pressurization pressure can reach 3000kN, pressurization is carried out by hydraulic pump.

[0135] (5) Two upper and lower temperature regulating plates made of aluminum alloy with a size of 700 mm (film width direction)×1000 mm (film moving direction) are installed in the pressurizing device, and each is connected to a heating device and a cooling device. The mold is installed on the temperature regulating plate on the lower side. The heating device was a heat medium circulation device, and the heat medium was Baresam #400 (manufactured by Matsumura Petroleum Co., Ltd.), and the heat medium heated to 150°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com