Novel chill coating sand core mold capable of exhausting air

A chilled iron and sand core technology, which is applied in the mold field of new chilled iron outsourcing sand cores, can solve problems such as nest gas and product gas that cannot be discharged smoothly, and achieve the effect of simple structure and reduced casting cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

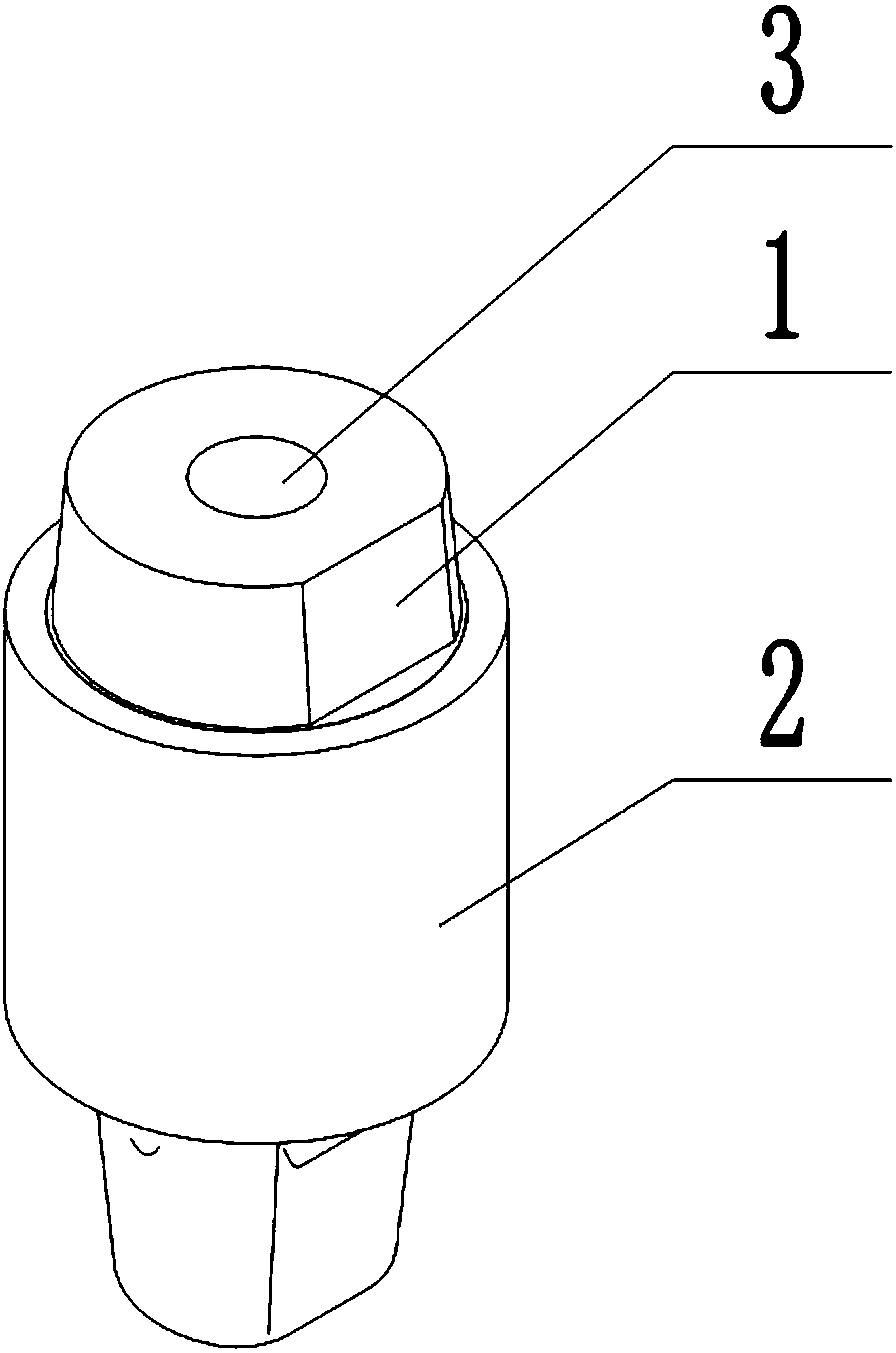

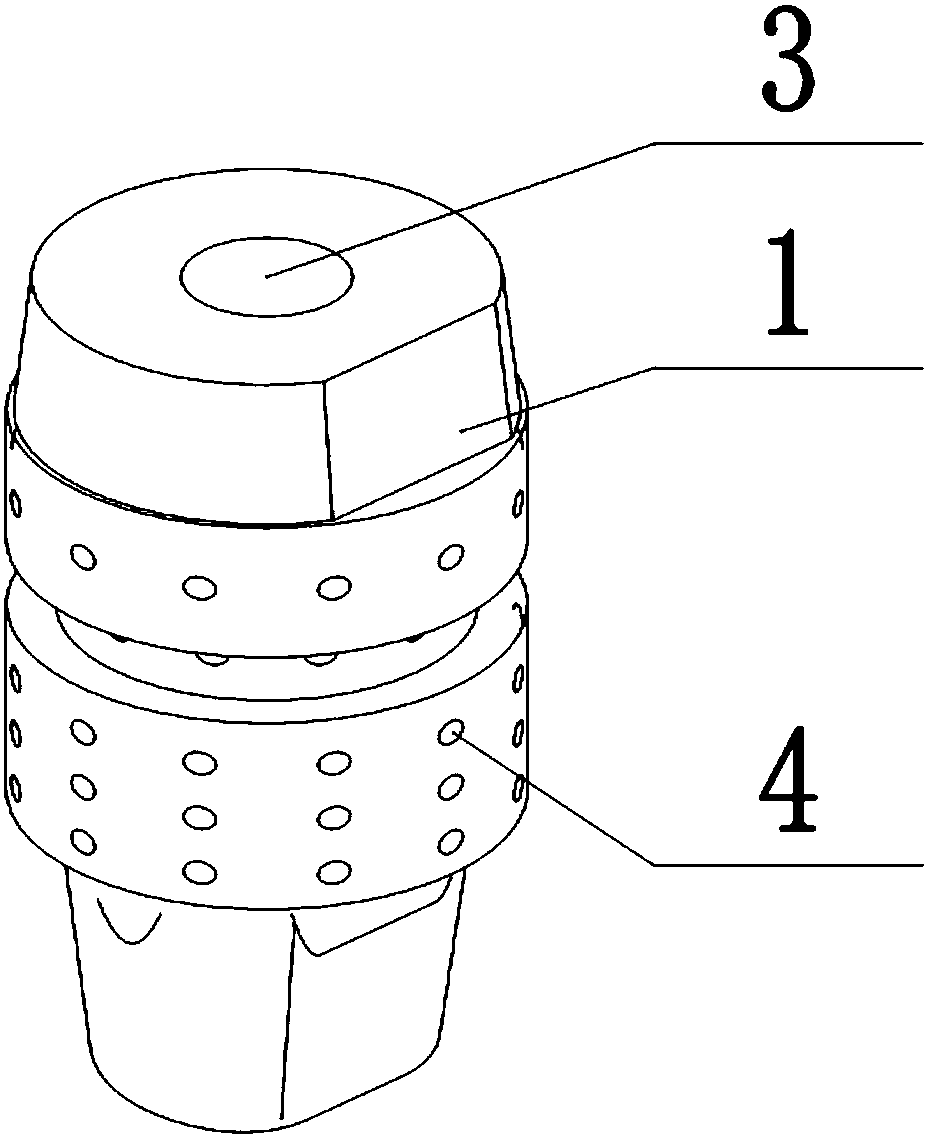

[0016] Such as Figure 1 to Figure 3 As shown in the figure, a new type of air-cooled iron-wrapped sand core mold includes a central chilled iron 1 with a sand core 2 on the periphery of the central chilled iron 1, and a central core runs through the center chilled iron 1 from top to bottom. Exhaust hole 3, the side wall of the central cold iron 1 in contact with the sand core 2 has multiple rows of exhaust small holes 4 drilled from top to bottom, and the exhaust small holes 4 extend into the central cold iron 1 And communicate with the central exhaust hole 3 .

[0017] The horizontal section of the central exhaust hole 3 is circular, and the diameter of the exhaust small hole 4 is 3 mm.

[0018] There are five rows of exhaust holes 4, and each row is provided with ten exhaust holes 4.

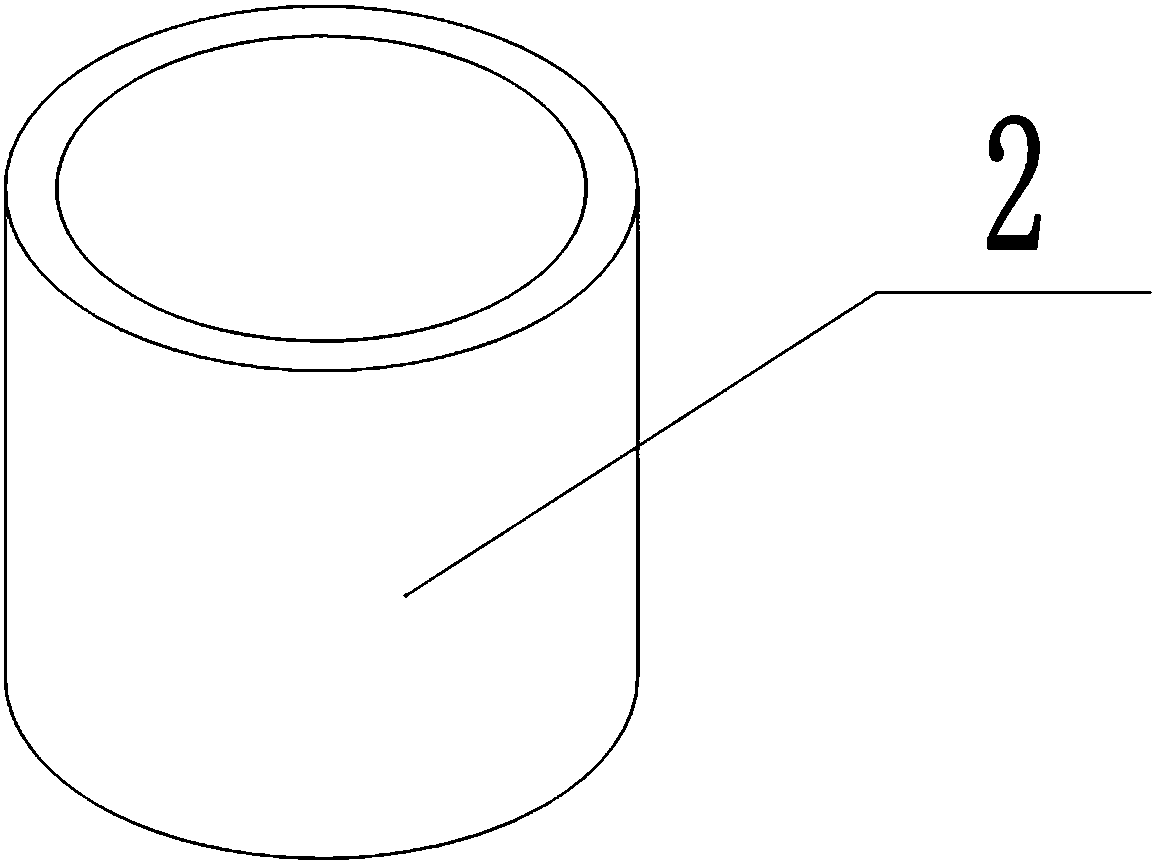

[0019] The sand core 2 is a hollow cylindrical structure.

[0020] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com