Hydrogen peroxide concentration and purification device and application thereof to hydrogen peroxide concentration and purification

A hydrogen peroxide, concentration technology, applied in the directions of peroxide/peroxyhydrate/peroxyacid/superoxide/ozone, inorganic chemistry, vapor condensation, etc. problems, to achieve the effect of improving product purity, increasing yield and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

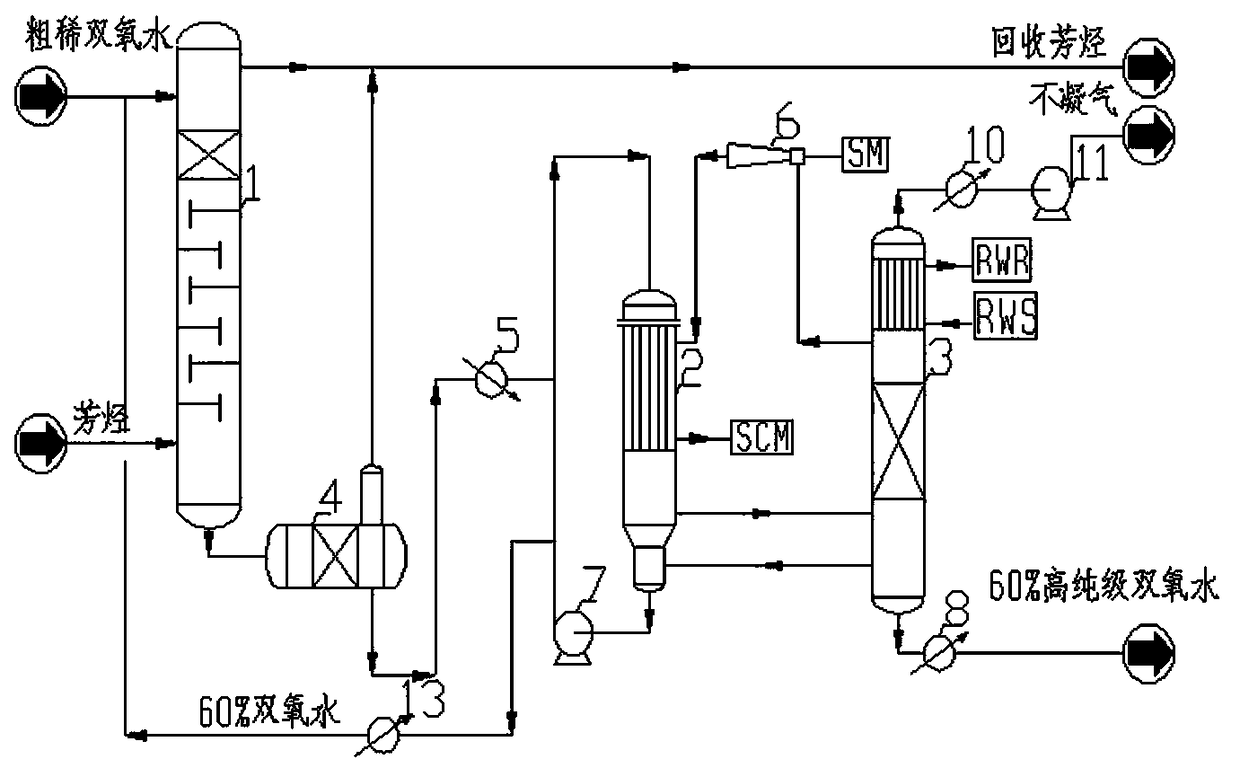

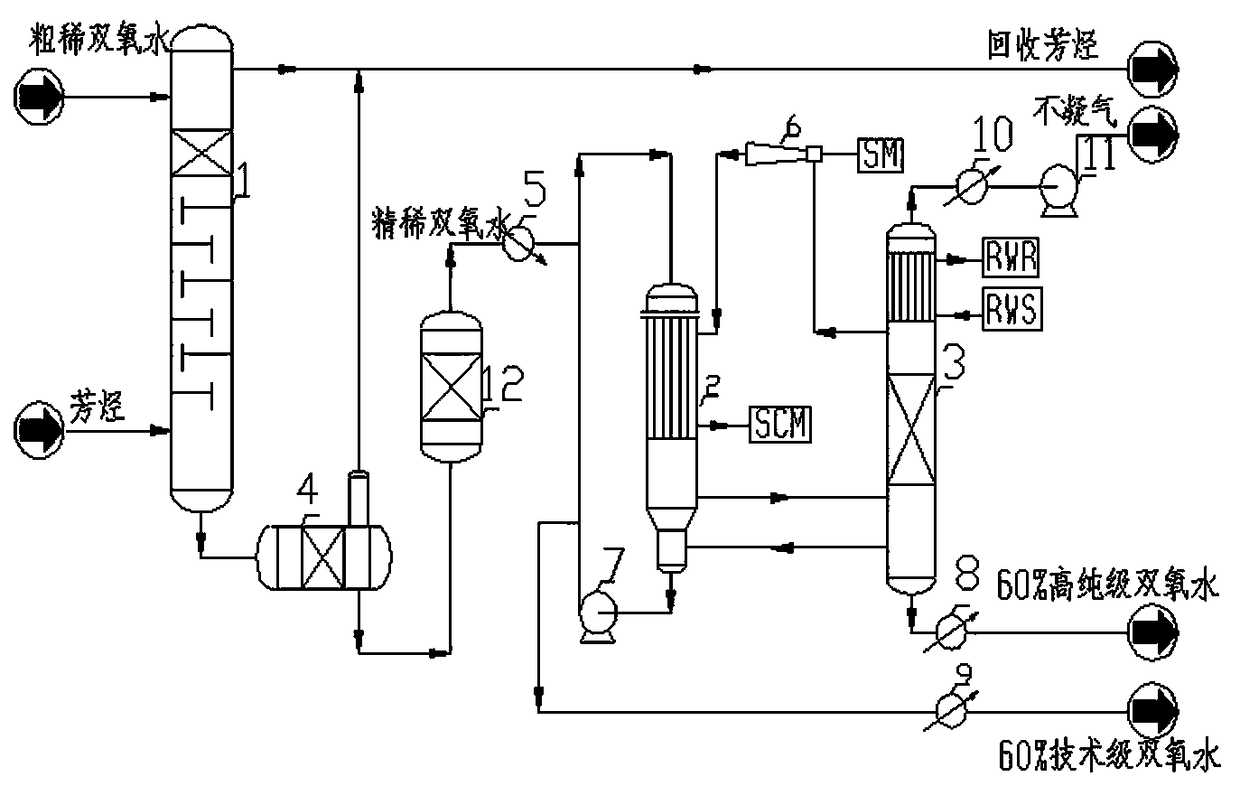

[0033] attached figure 1 The shown hydrogen peroxide concentration and purification device is mainly composed of a purification tower 1, a coalescer 4, a preheater 5, a falling film evaporator 2, a rectification tower 3, a steam jet pump 6, a centrifugal pump 7, a circulating cooler 13, a refining Distillation tower top condenser 10, vacuum pump 11 and high-purity hydrogen peroxide cooler 8 are composed.

[0034] The concentration of crude hydrogen peroxide sent from the extraction process is 25-45%, and the TOC is 200-800ppm. It enters the purification tower at the upper part of the tower, and the aromatics enter the purification tower from the lower part of the tower. The theoretical plate number of the purification tower is 13. The aromatics The weight ratio with crude hydrogen peroxide is 0.01-0.10. The temperature of the purification tower is 15-45°C, and the operating pressure is normal pressure.

[0035] After passing through the purification tower, the TOC of hydroge...

Embodiment 2

[0039] The concentration of crude hydrogen peroxide sent from the extraction process is 25%, and the TOC is 200-800ppm. It enters the purification tower at the upper part of the tower, and the aromatics enter the purification tower from the lower part of the tower. The theoretical plate number of the purification tower is 15. The weight ratio of hydrogen peroxide is 0.03-0.05. The temperature of the purification tower is 20-40°C, and the operating pressure is normal pressure.

[0040] After passing through the purification tower, the TOC of hydrogen peroxide from the lower part of the purification tower is 100-350ppm. After entering the coalescer to separate the organic matter, it is sent to the preheater to preheat to 33-38°C, and then sent to the falling film evaporator for heating. The heating temperature is 75-80°C, using medium-pressure steam to drive the evaporation jet pump steam as the heat source; the concentration of the lower part of the falling film evaporator is 18-...

Embodiment 3

[0044] The concentration of crude hydrogen peroxide sent from the extraction process is 45%, and the TOC is 200-800ppm. It enters the purification tower at the upper part of the tower, and the aromatics enter the purification tower from the lower part of the tower. The theoretical plate number of the purification tower is 8. The weight ratio of hydrogen peroxide is 0.03-0.05. The temperature of the purification tower is 15-40°C, and the operating pressure is normal pressure.

[0045] After passing through the purification tower, the TOC of hydrogen peroxide from the lower part of the purification tower is 100-350ppm. After entering the coalescer to separate the organic matter, it is sent to the preheater to preheat to 33-38°C, and then sent to the falling film evaporator for heating. The heating temperature is 75-80°C, using medium-pressure steam to drive the evaporation jet pump steam as the heat source; the concentration of the lower part of the falling film evaporator is 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com