Systems and methods for low-temperature gas separation

A low-temperature, hydrocarbon gas technology, applied in the field of low-temperature gas separation systems, can solve problems such as high energy consumption and pressure loss of mixtures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

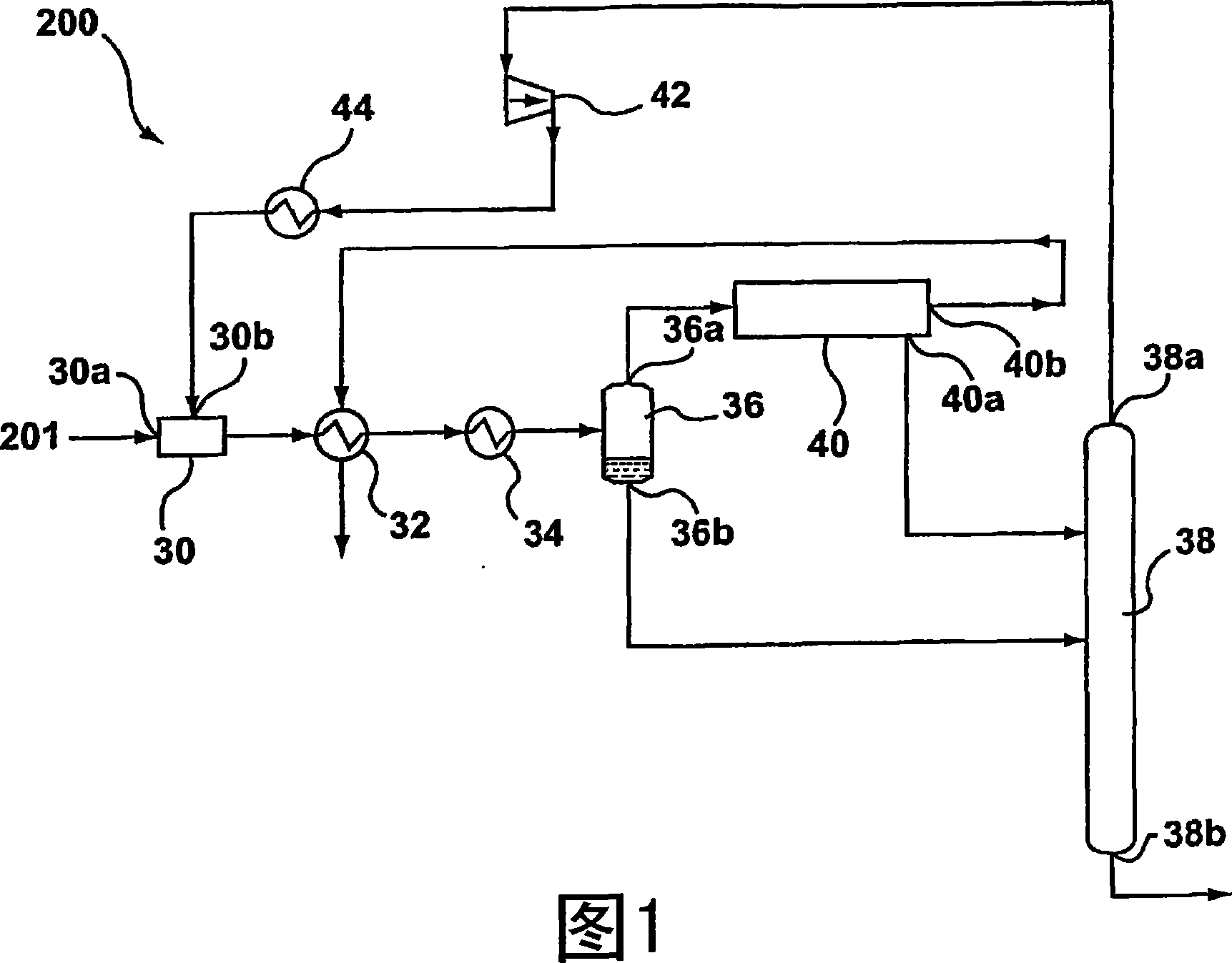

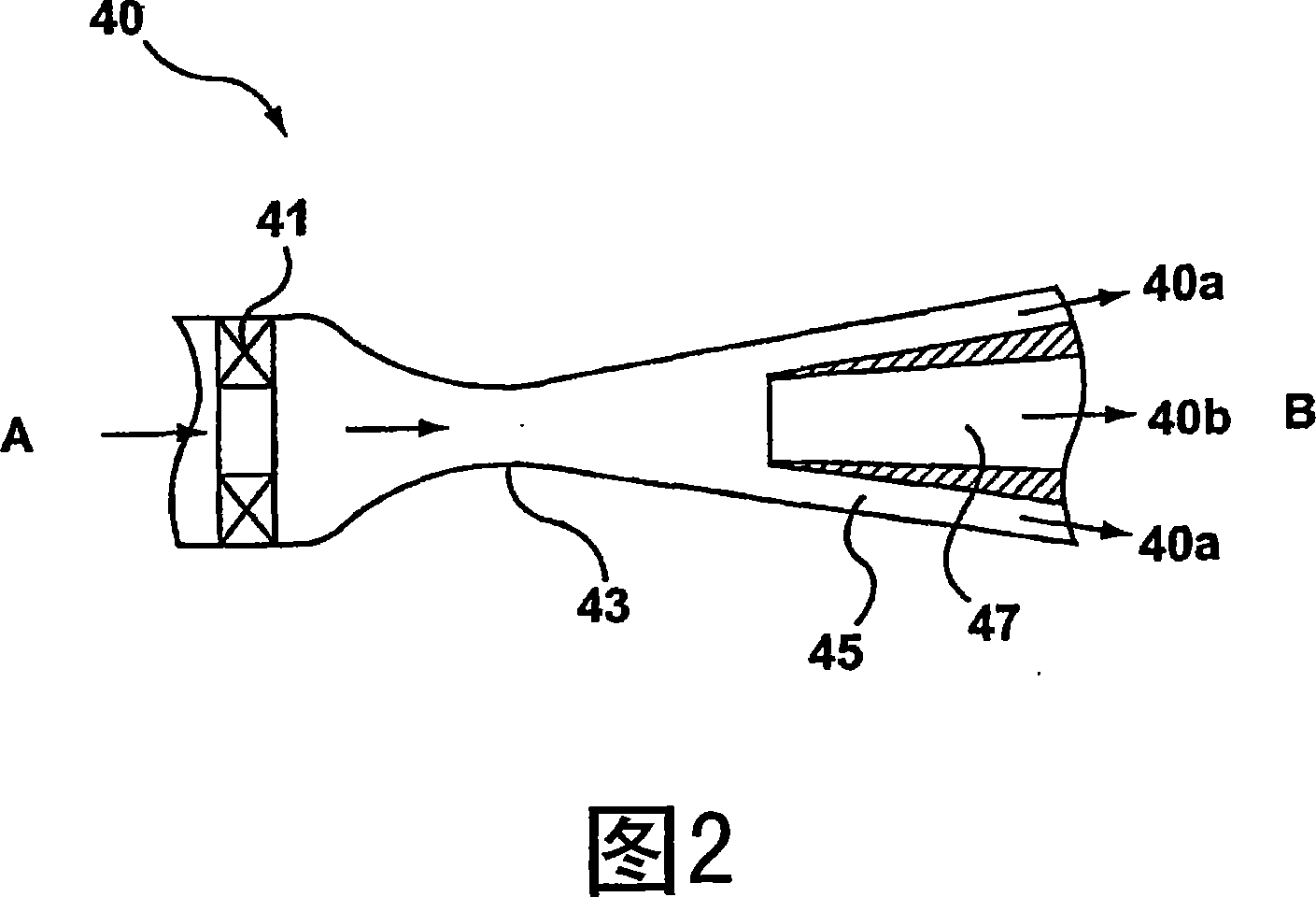

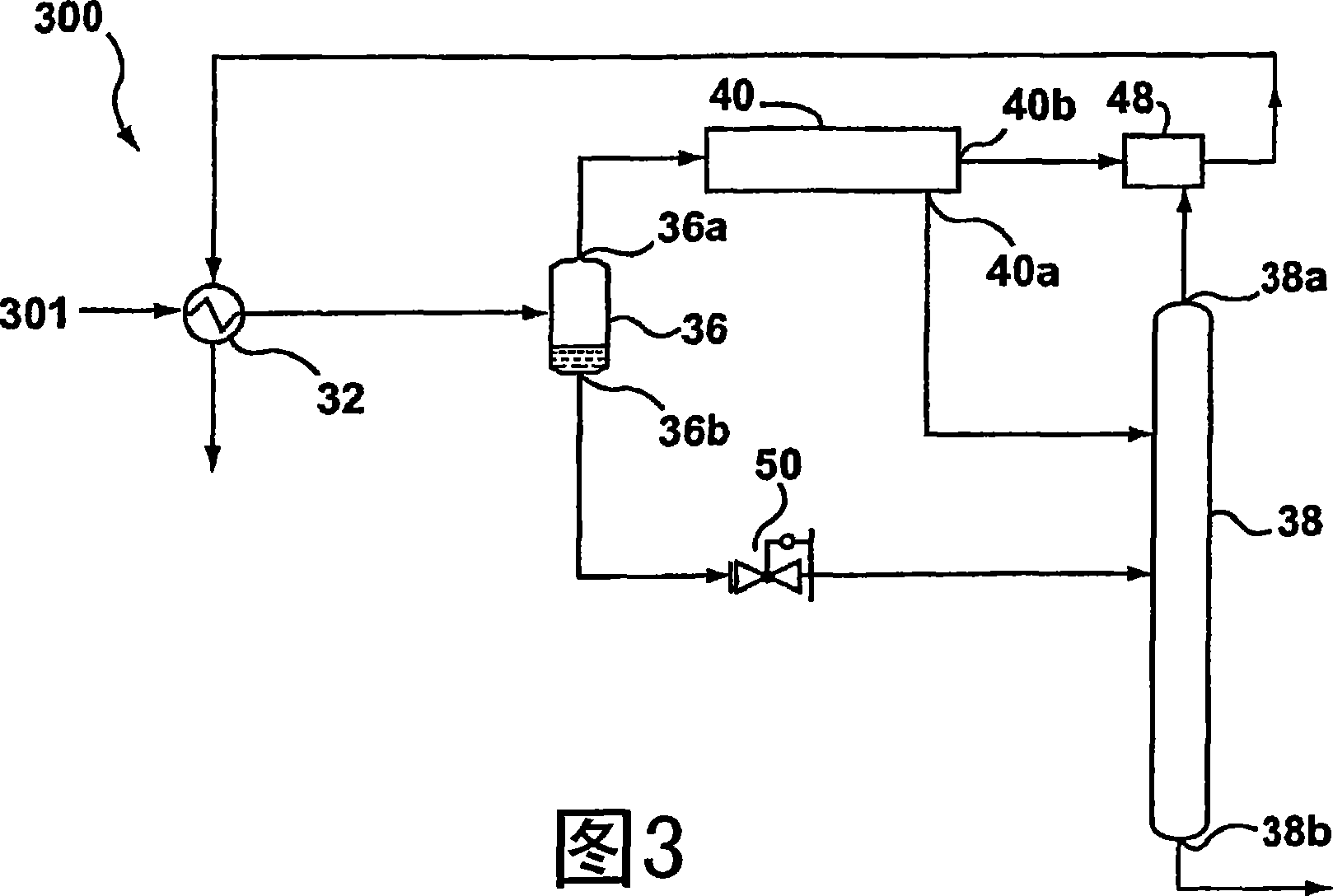

[0072] Some embodiments of the invention can reduce power consumption in LTS facilities. With regard to this aim, according to some embodiments of the invention, it can be achieved in the first embodiment of the invention due to the fact that in the known LTS process for hydrocarbon gas mixtures, it consists of cooling the mixture, without doing mechanical expansion of the mixture or a part thereof, partial condensation of the mixture during its expansion, separation of the mixture or a part thereof in a rectification column to obtain liquid and gas phase products, according to the invention the expansion of the mixture is achieved by passing the mixture through a nozzle channel whereby the mixture stream is swirled in the nozzle channel and / or at the inlet of the nozzle channel, and at the outlet of the nozzle channel or a portion thereof the mixture stream is split into at least two streams, one stream being enriched in methane heavy components, while the other stream is def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com