Cobaltous sulfate solution evaporation system and process thereof

A technology of cobalt sulfate solution and evaporation system, applied in cobalt sulfate, evaporation, evaporator accessories, etc., to achieve the effects of low investment cost, height reduction, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further illustrate technical means, novelty and purpose effect of the present invention, in conjunction with actual setting forth embodiment, but following embodiment is exemplary, only for explaining this invention, and can not be interpreted as limitation of the present invention.

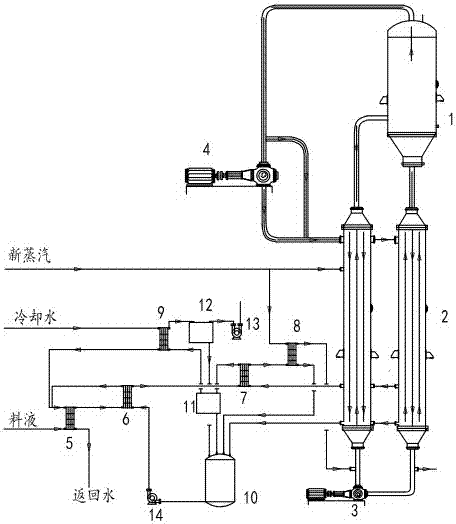

[0021] As shown in the figure, a cobalt sulfate solution evaporation system includes an evaporation unit, a vacuum unit, a preheating unit and connecting pipes; the evaporation unit includes a separator 1, an evaporator 2, a forced circulation pump 3, a steam compressor 4, and a separator 1 The secondary steam outlet is directly connected to the evaporator 2 through pipelines and indirectly through the steam compressor 4. The evaporators 2 are two groups parallel and connected through the forced circulation pump 3; the vacuum unit includes two-stage condensers 7, 9, two-stage gas Liquid separator 11, 12, vacuum pump 13 and condensate tank 10; the preheating unit includes four pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com