Leaf plant cell sap extraction device and process

A plant cell and extraction device technology, applied in grain processing, steam condensation, evaporator adjustment/control, etc., can solve the problems of incomplete extraction, inability to extract all cell fluids, and difficulty in breaking, and achieve high extraction rate and good quality , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

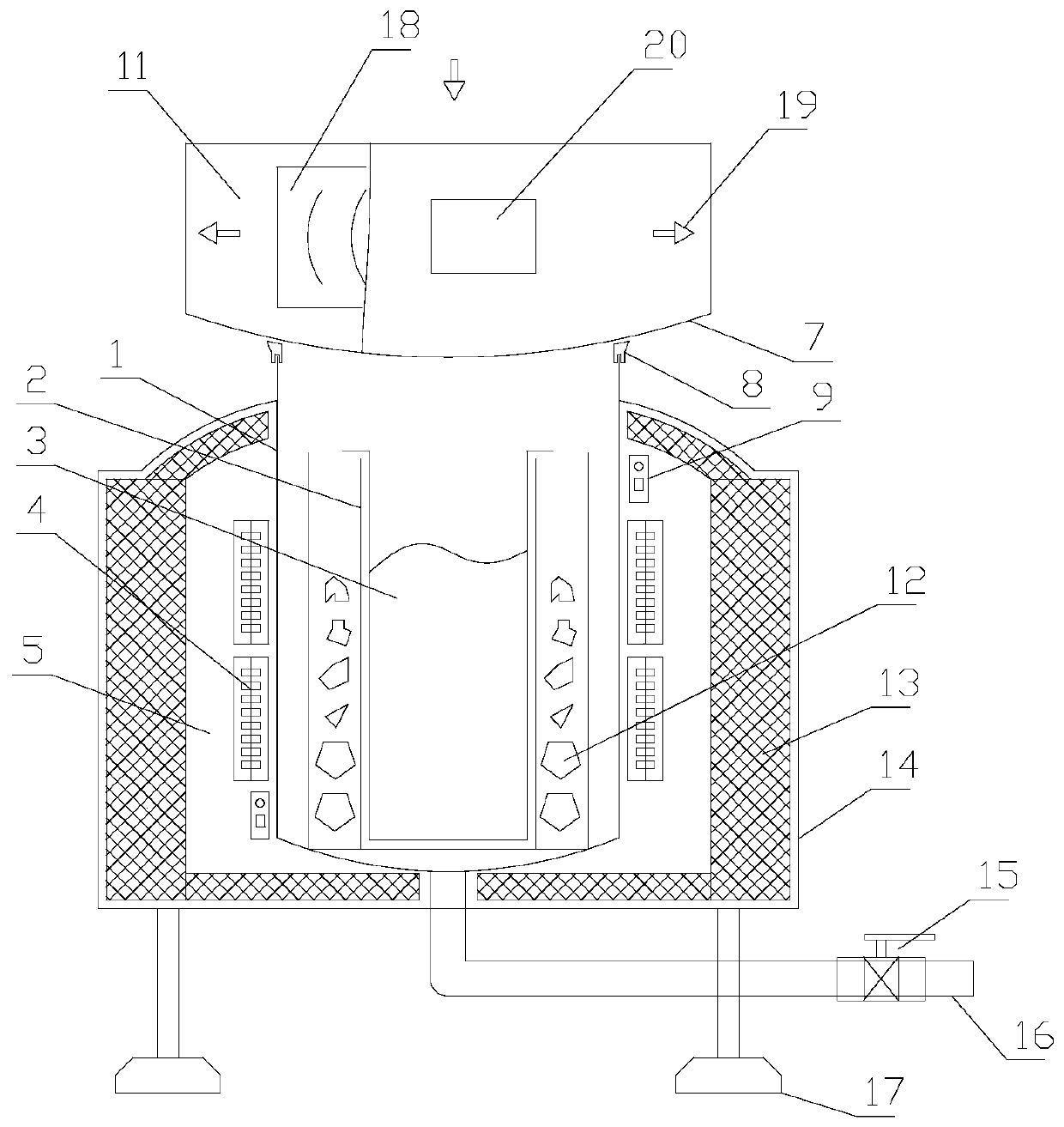

[0037] see figure 1 , the present invention provides a device for extracting leaf plant cell sap, comprising a casing 14, an inner tank 1, and a cover 19, the cover is used to cover the opening at the upper end of the inner tank 1, and the cover and the opening of the inner tank are arranged Sealing device (see sealing ring 8), the controller is arranged in the cover body or in the shell, the operation display screen 20 is installed on the side wall of the cover body, the operation display screen 20 and the heater 4 are connected to the controller, and the operation display screen 20 inputs Including heating temperature, pressure, time and other control instructions, the heater 4 is driven by the controller, and a ring-shaped mesh basket 2 is placed in the inner tank, with roses, orange peels, broccoli and other extracts built in, and there is also a cup in the inner tank 3. The container cup 3 is placed in the center ring of the mesh basket, and the heater is used to heat the...

Embodiment 2

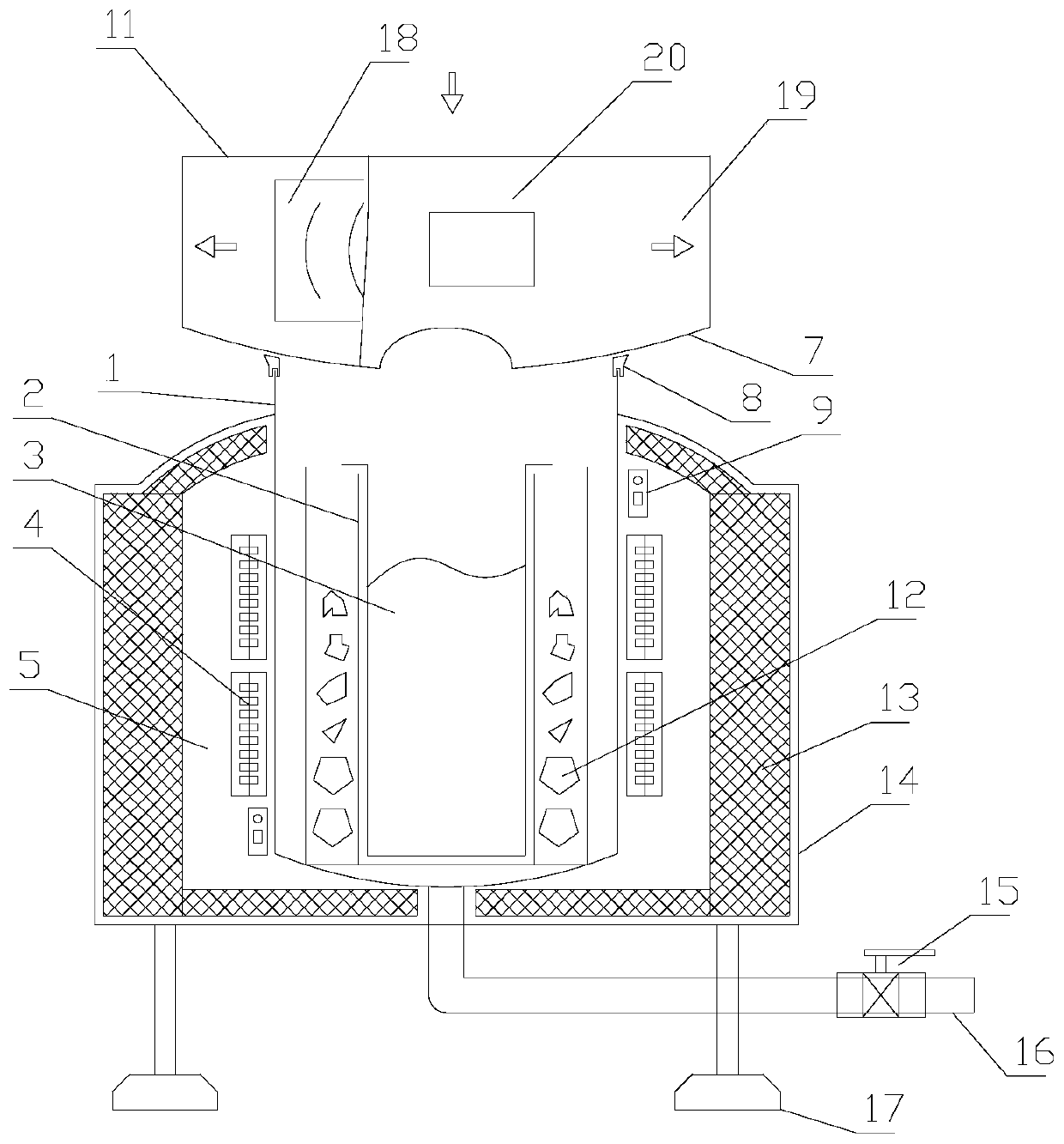

[0045] see figure 2 , this embodiment is further improved on the basis of Embodiment 1, specifically, the bottom wall 7 of the cover body includes a central area and an outer ring area, the outer ring area arches downward toward the central area, and the central area Then the upward arc is arched to form an arched circle structure, and the contour line connecting the outer ring area and the central area is positively projected in the container. This structure can also make the cell fluid attached to the surface of the bottom wall slide to the outside along the arc surface. The junction of the ring area and the center area, then drips into the container. The rest of the structure of this embodiment is the same as that of Embodiment 1.

Embodiment 3

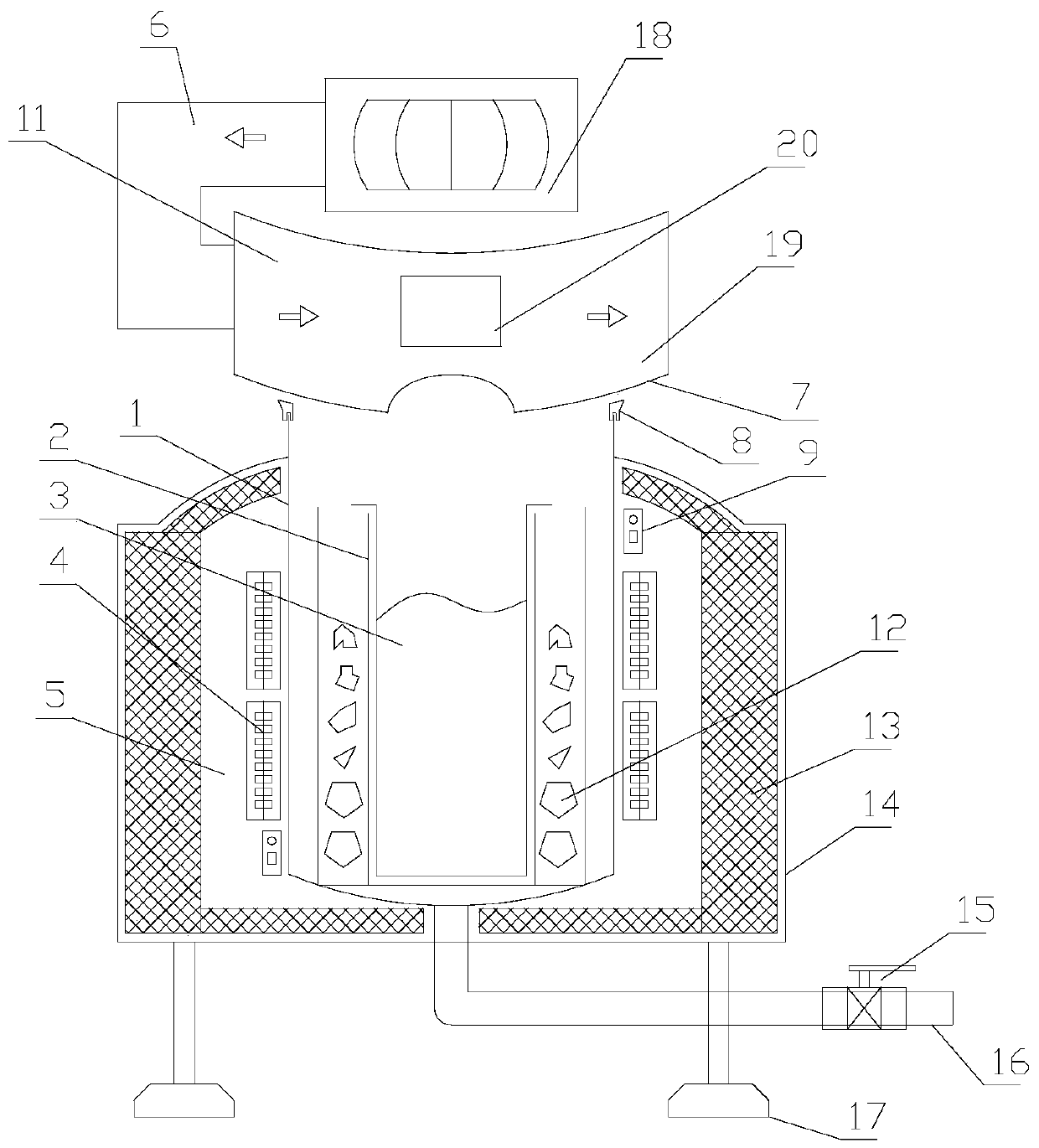

[0047] see image 3 , this embodiment is further improved on the basis of Embodiment 2, specifically, the cooling fan 18 is placed outside, the air inlet and outlet of the cooling air chamber 11 are respectively opened on the side wall of the cover body, and the air inlet of the cooling air chamber passes through The external air duct 6 is connected to the air outlet of the cooling fan 18 . The rest of the structure of this embodiment is the same as that of the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com