Titanium dioxide photocatalysis air-cleaning film and its preparation method

A technology of photocatalytic thin film and titanium dioxide, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. It can solve problems such as technical limitations, affecting air purification effects, and affecting photocatalytic reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

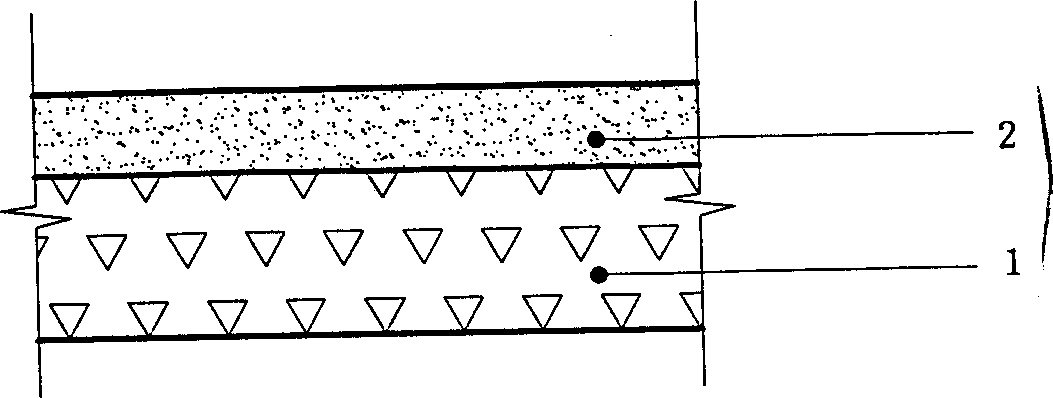

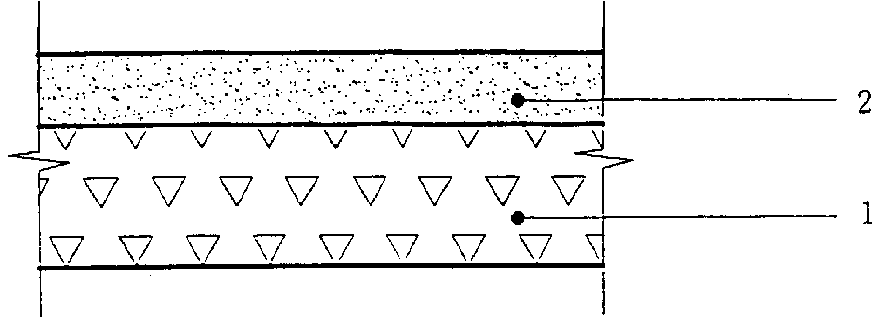

Image

Examples

Embodiment 1

[0021] Using glass as the carrier, put it into the vacuum coating equipment after cleaning, using the medium frequency AC magnetron sputtering method, the frequency range of the medium frequency AC arc suppression power supply is 15KHz, and the background vacuum pressure is 3.0×10 -3 Pa, the working gas is argon, with a purity of 99.99%; the working gas is 0.5Pa; the reaction gas is oxygen, with a purity of 99.99%, and the partial pressure of oxygen is 0.1Pa; the temperature of the carrier during film deposition is 150°C; the magnetron sputtering time 40 minutes.

[0022] Under the above conditions, the obtained titanium dioxide film is composed of anatase phase, rutile phase and a small amount of amorphous composition, wherein the relative proportion of anatase phase to anatase and rutile is about 88%, and the rutile phase accounts for anatase and rutile. The relative proportion of rutile is 12%, the thickness of the film is about 45nm, and the grain size is 30-40nm. The ult...

Embodiment 2

[0025] Using glass ceramics as the carrier, put it into the vacuum coating equipment after cleaning, using the medium frequency AC magnetron sputtering method, the frequency range of the medium frequency AC arc suppression power supply is 20KHz, and the background vacuum pressure is 3.0×10 -3 Pa, the working gas is argon, with a purity of 99.99%; the working gas is 1.2Pa; the reaction gas is oxygen, with a purity of 99.99%, and the partial pressure of oxygen is 0.12Pa; the temperature of the carrier during film deposition is 300°C; the magnetron sputtering time is 40 minute.

[0026] Under the above conditions, the obtained titanium dioxide film is composed of mixed phases of anatase phase and rutile phase, wherein the relative proportion of anatase phase to anatase and rutile is about 92%, and rutile phase accounts for anatase and rutile. The relative ratio is 8%, the thickness of the film is about 500nm, and the grain size is 30-40nm. The ultraviolet light absorption rate o...

Embodiment 3

[0029]Use metal aluminum as the carrier, put it into the vacuum coating equipment after cleaning, use the medium frequency AC magnetron sputtering method, the frequency range of the medium frequency AC arc suppression power supply is 40KHz, and the background vacuum pressure is 4.0×10 -3 Pa, the working gas is argon, the purity is 99.99%; the working gas is 2.0Pa; the reaction gas is oxygen, the purity is 99.99%, the partial pressure Pa of oxygen; the temperature of the carrier during film deposition is 400 ° C; the magnetron sputtering time is 40 minutes .

[0030] Under the above conditions, the obtained titanium dioxide film is composed of mixed phases of anatase and rutile, wherein the anatase phase accounts for about 95% of the relative proportion of anatase and rutile, and the rutile phase accounts for anatase and rutile. The relative proportion is 5%, the thickness of the film is about 55nm, and the grain size is ~40nm. The ultraviolet light absorption rate of the film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com