In-situ test method for high-pressure low-temperature heat conductivity coefficients and heat transfer coefficients

A high-pressure, low-temperature, heat transfer coefficient technology, applied in the direction of material thermal conductivity, material thermal development, etc., can solve problems such as poor ease of use and convenient operation, changes in the physical properties and states of multi-phase substances, and large measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

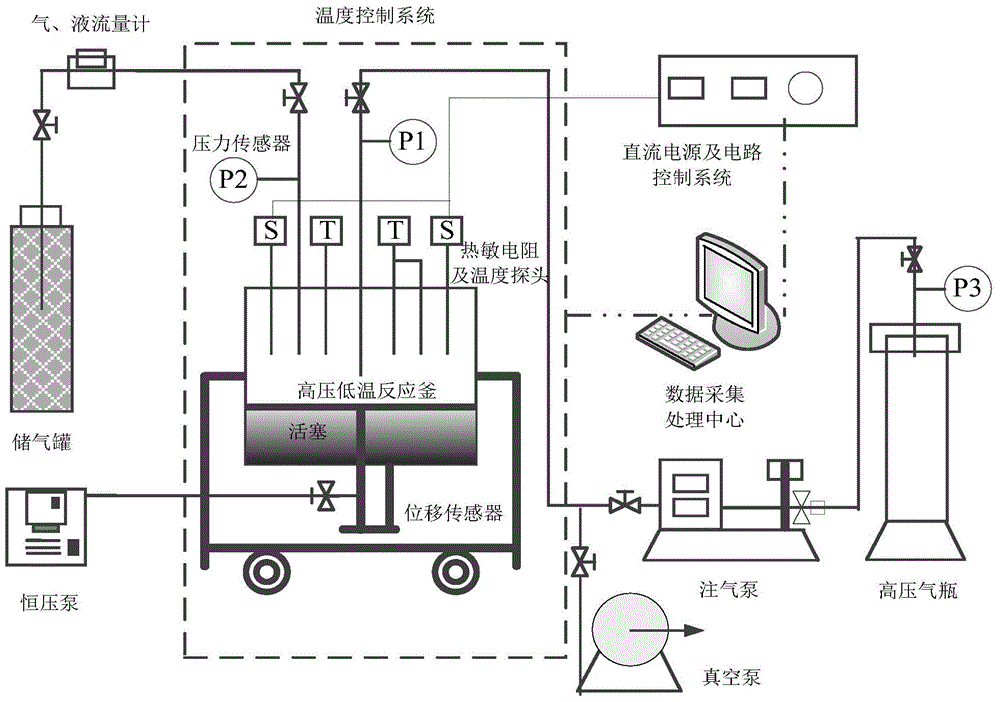

[0037] The decomposition of methane hydrate in porous media is a process of multi-phase coexistence under high pressure and low temperature conditions, accompanied by a phase change process. It is difficult to measure the thermal conductivity of different stages and the heat transfer coefficient of the decomposition process by conventional traditional methods. Following is the test implementation process of the present invention:

[0038] First, open the top cover of the reactor and select methane hydrate to generate in situ in the porous medium:

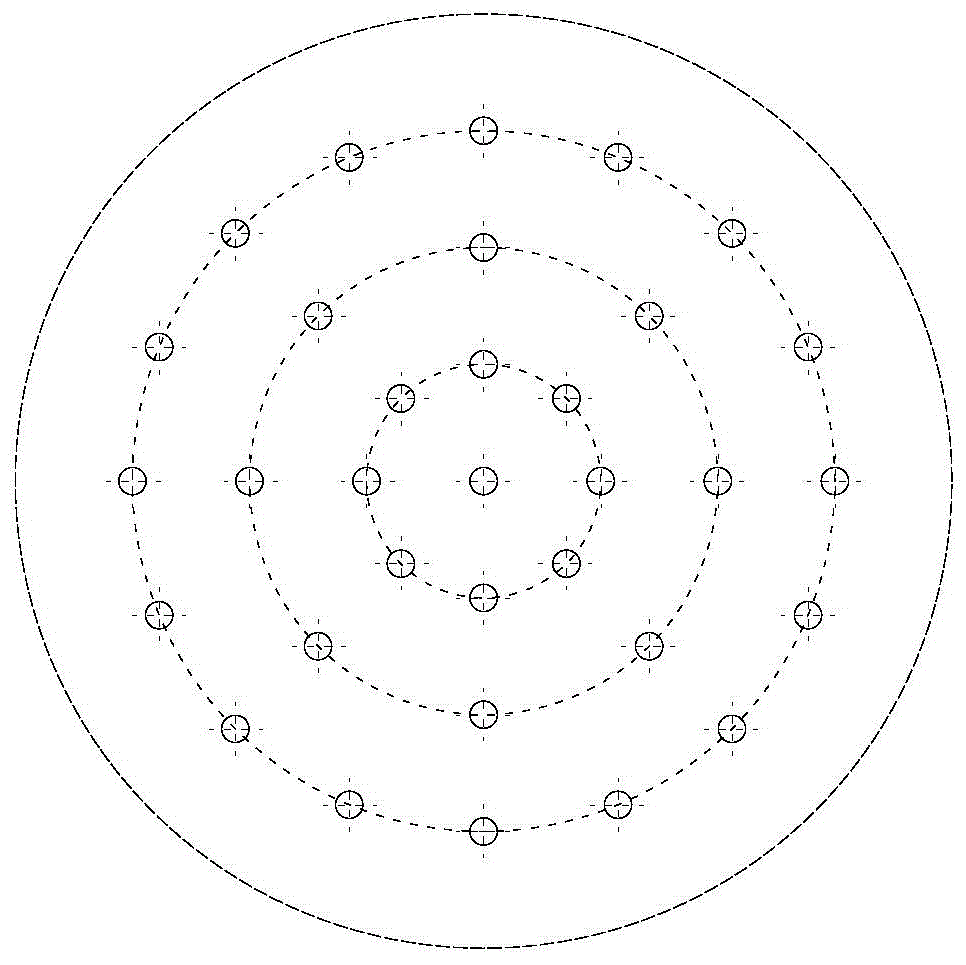

[0039] 1. Choose 6Kg glass sand (particle size is 0.4mm, porosity is 0.36, density is 2.58g / cm 3 ,) placed in the reactor, 1Kg deionized water and glass sand were evenly mixed. Close the reactor, insert the temperature sensor, thermistor probe, pressure sensor, and connect the pipeline.

[0040] 2. Open the inlet and outlet valves at the top of the reactor, use a constant flow pump to slowly inject ethylene glycol solution (low te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com