Water turbine rotating wheel and manufacturing method thereof

A manufacturing method and technology of water turbines, which are applied in the direction of final product manufacturing, sustainable manufacturing/processing, hydropower generation, etc., can solve the problems such as the inability to transport the whole runner, the high cost, and the heavy weight of the water turbine runner.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

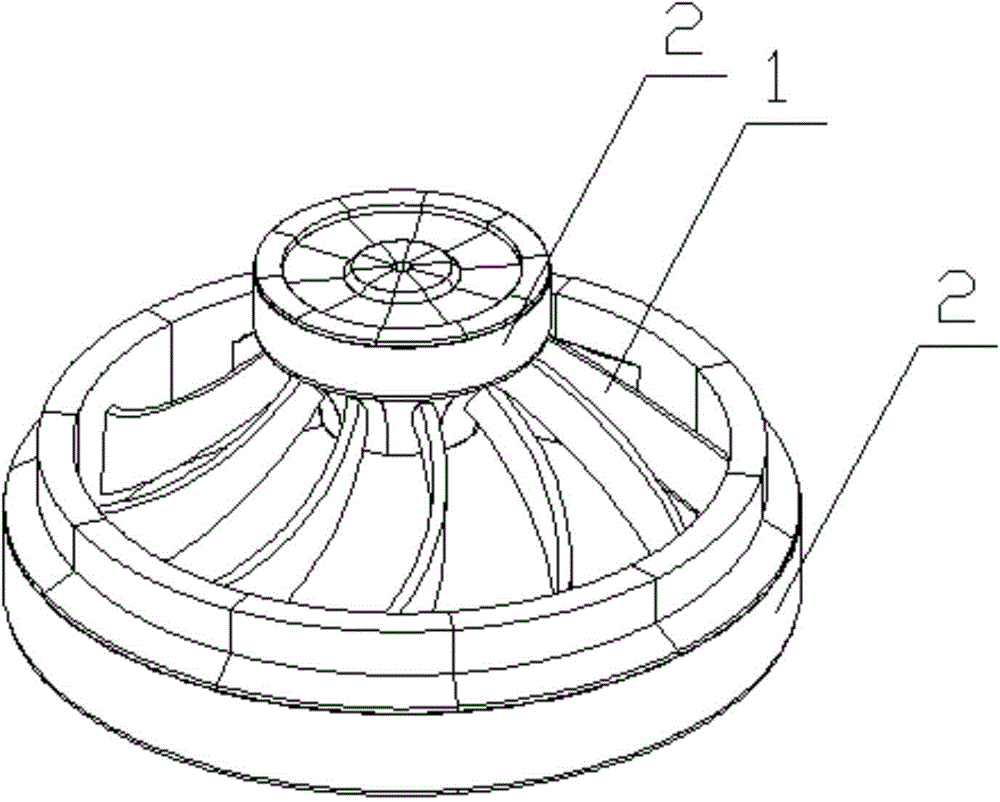

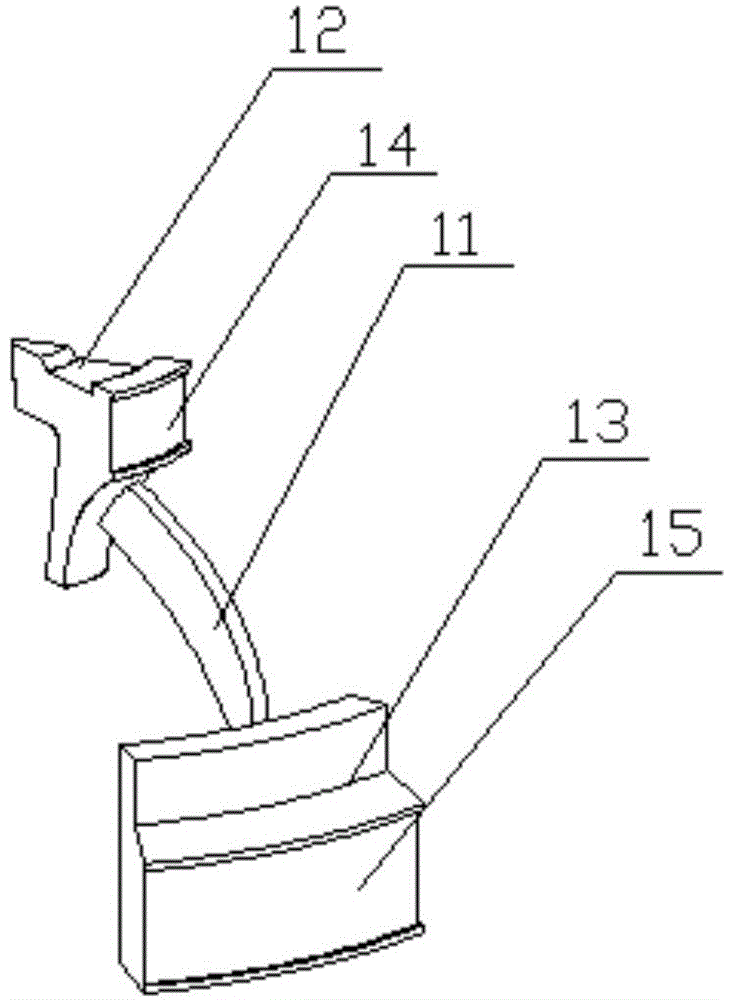

[0027] Embodiment: a water turbine runner, including a blade body 1 and first and second steel wire winding layers, said blade body 1 includes a water turbine blade 11 and an upper crown portion 12 and a lower ring portion 13 positioned at both ends of the blade, The sidewalls of several blade bodies 1 are fixedly connected in turn to form a ring structure, the upper crown parts 12 of each blade body 1 are spliced to form the upper crown of the ring structure, and the lower ring parts 13 of each blade body 1 are spliced to form the ring structure. In the lower ring of the circular structure, the first steel wire winding layer is tightly wrapped around the upper crown of the ring structure, and the second steel wire winding layer is tightly wrapped around the lower ring outside of the ring structure.

[0028] The oversized and overweight water turbine runner is decomposed into several blade bodies 1, each blade body 1 contains a complete blade, the corresponding part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com