Preparation method of multilayer-coated slow release fertilizer for wheat

A technology of coated slow-release and wheat, which is applied in the preparation of organic fertilizers, layered/coated fertilizers, nitrogen fertilizers, etc., can solve the problems of difficult degradation of coated materials, restrictions on large-scale use, and expensive coated fertilizers. Facilitate absorption, improve soil nutrient status, prevent premature aging and defertilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

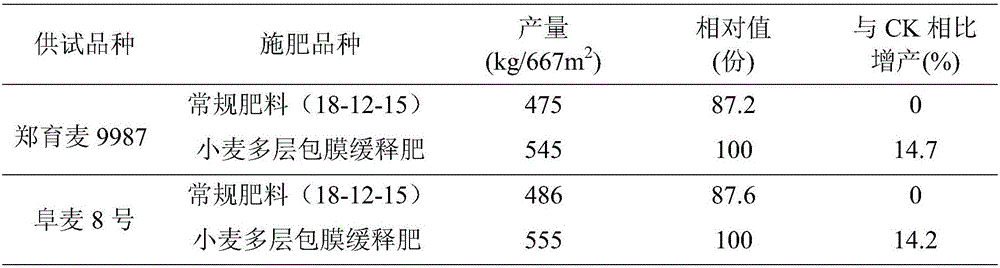

Examples

Embodiment 1

[0024] In the present embodiment, a preparation method of wheat multi-layer coated slow-release fertilizer comprises the following steps:

[0025]S1. Mix nitrogen fertilizer, 2-chloro-6-trichloromethylpyridine, diammonium phosphate, potassium sulfate, medium and trace element fertilizer, kaolin and modified cassava flour, grind them and send them to a granulator for granulation Particles, get the core particles;

[0026] S2. After aging the concentrated sulfuric acid, phosphoric acid and liquid ammonia to obtain a slurry, spray the slurry into a granulator, add the core particles obtained in S1 to granulate, and obtain particles with an inner coating layer, and then Dry and sieve to a particle size of 3-4mm;

[0027] S3. After humidifying the granules with an inner coating layer obtained in S2, they are sent into a granulator, and an outer coating material is added for granulation to obtain granules with an outer coating layer;

[0028] S4, drying the granules with an outer ...

Embodiment 2

[0034] In the present embodiment, a preparation method of wheat multi-layer coated slow-release fertilizer comprises the following steps:

[0035] S1. Mix nitrogen fertilizer, nitrogen fertilizer synergist, phosphate fertilizer, potassium fertilizer, medium and trace element fertilizer, auxiliary materials and modified cassava flour, pulverize them and send them to a granulator for granulation to obtain core granules;

[0036] S2. After aging the concentrated sulfuric acid, phosphoric acid and liquid ammonia to obtain a slurry, spray the slurry into a granulator, add the core particles obtained in S1 to granulate, and obtain particles with an inner coating layer, and then Dry and sieve to a particle size of 3-4mm;

[0037] S3. After humidifying the granules with an inner coating layer obtained in S2, they are sent into a granulator, and an outer coating material is added for granulation to obtain granules with an outer coating layer;

[0038] S4, drying the granules with an o...

Embodiment 3

[0044] In the present embodiment, a preparation method of wheat multi-layer coated slow-release fertilizer comprises the following steps:

[0045] S1. Mix organic nitrogen fertilizers, inorganic nitrogen fertilizers, nitrogen fertilizer synergists, phosphate fertilizers, potassium fertilizers, medium and trace element fertilizers, auxiliary materials and modified cassava flour, grind them and send them to a granulator for granulation to obtain core granules ;

[0046] S2. After aging the concentrated sulfuric acid, phosphoric acid and liquid ammonia to obtain a slurry, spray the slurry into a granulator, add the core particles obtained in S1 to granulate, and obtain particles with an inner coating layer, and then Dry and sieve to a particle size of 3-4mm;

[0047] S3. After humidifying the granules with an inner coating layer obtained in S2, they are sent into a granulator, and an outer coating material is added for granulation to obtain granules with an outer coating layer; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com