Clarification method of flue gas saturated with mixed liquid

A technology for mixing juice and flue gas, applied in the direction of using oxidation/reduction purification, etc., can solve the problems of high sulfur content in white sugar, insufficient product quality, stable carbonation method, etc., to reduce the conversion of sucrose, improve the purity, and improve the product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Describe in detail below in conjunction with embodiment.

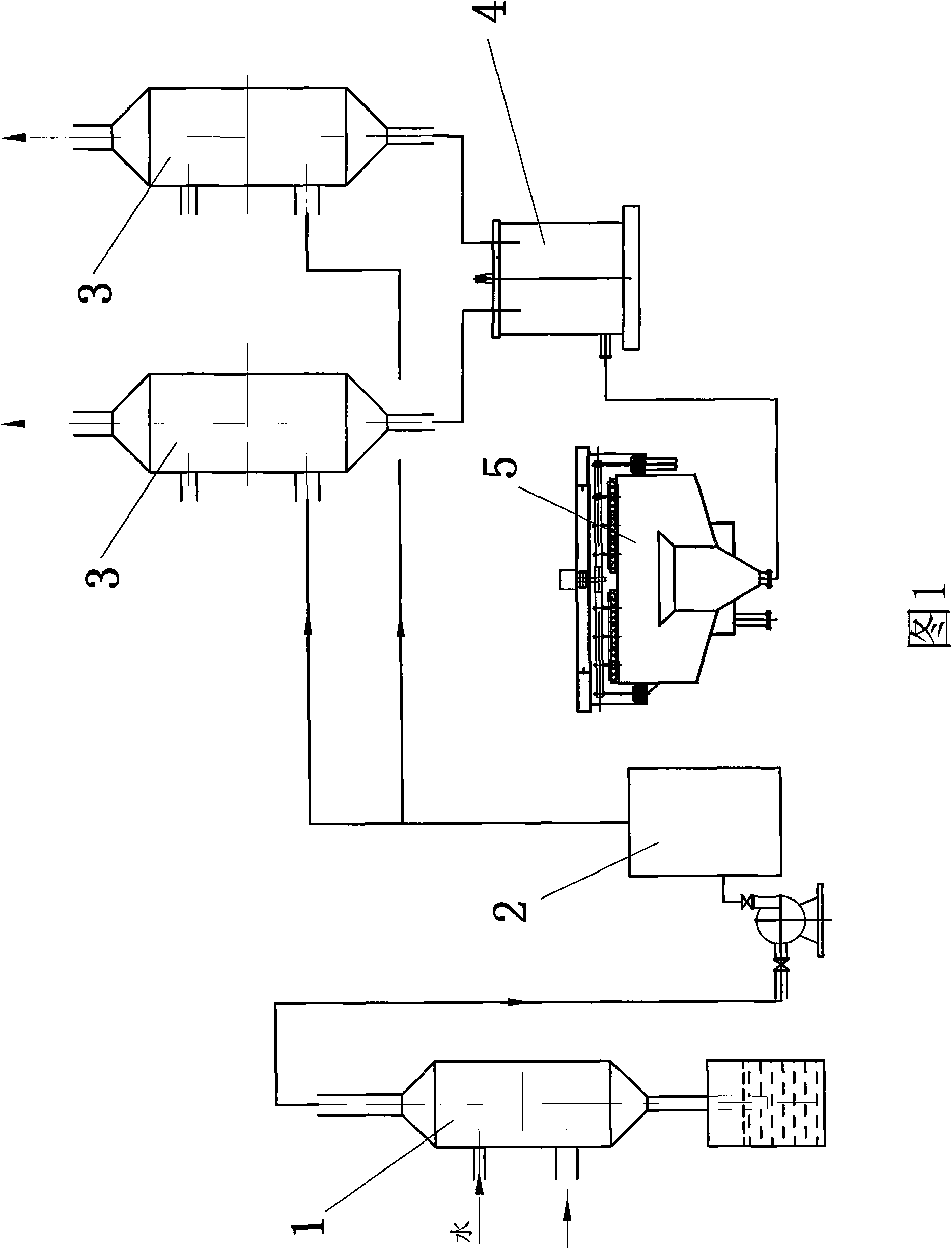

[0013] The flue gas at the outlet of the boiler is extracted by a high-power fan or a vacuum pump, and most of the soot and impurities are removed through the treatment of the water film dust collector 1, and then enters the gas storage tank 2, and then is sent to the filling tank 3; the squeezed mixed juice is passed through After adding phosphoric acid and pre-ashing to PH 7.5-8.0 (the effective phosphoric acid value can be reduced from 400-450ppm without flue gas filling to 300-350ppm), heat to 65-70°C once, pump until the tank is full, and mix the juice The flue gas flows from the top down, and the flue gas goes from the bottom to the top. After the two are fully contacted and reacted, the mixed juice enters a stirring tank 4, is fully stirred, and then enters the floater 5 from the stirring tank. Before entering, add 2-3ppm flocculant, The mixed juice after flotation is then pumped for sulfur fumigation and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com