Method for cleaning refractory cane juice for sugar factories by using sulfurous method

A sulphite sugar factory and cane juice technology, which is applied in the purification of sugar juice, sugar production, sucrose production, etc., can solve the problems of unsatisfactory product quality, achieve low cost, improve cleaning effect, and reduce content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

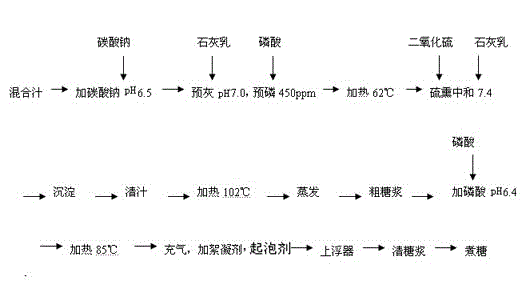

Method used

Image

Examples

Embodiment 1

[0024] Add 15% sodium carbonate aqueous solution by weight to 1000kg of squeezed mixed juice, adjust the pH of the mixed juice to 6.5, and then process the obtained solution according to the original sulfurous acid process until 300kg of crude syrup obtained by evaporation and concentration, and then add Food additive phosphoric acid to adjust the pH to 6.3, heat to 85°C, add 5ppm polyacrylamide and 0.3Kg sodium stearate and mix evenly, then fill in an appropriate amount of fine air bubbles from the bottom of the coarse syrup tank to allow non-sugar impurities such as colloids and pigments to enter The floater is separated from the syrup, and the quality of the clear syrup obtained is significantly improved. Afterwards, the original process is used to produce qualified white sugar. The test data of finished white sugar are shown in Table 1.

Embodiment 2

[0026] Add 15% sodium carbonate aqueous solution by weight to 1000kg of squeezed mixed juice, adjust the pH of the mixed juice to 6.7, and then process the obtained solution according to the original sulfurous acid process until 275kg of crude syrup obtained by evaporation and concentration, and then add Food additive phosphoric acid to adjust the pH to 6.4, heat to 80°C, add 5ppm polyacrylamide, 45ppm polyaluminum chloride, 0.2Kg sodium stearate and 0.1kg sodium laurate and mix well, then fill an appropriate amount from the bottom of the coarse syrup tank Fine air bubbles allow non-sugar impurities such as colloids and pigments to enter the floater to be separated from the syrup, and the quality of the obtained clear syrup is significantly improved. After that, the original process is used to produce qualified white sugar. The test data of finished white sugar are shown in Table 1.

Embodiment 3

[0028] Add 15% sodium carbonate solution to 1000kg of squeezed mixed juice, adjust the pH of the mixed juice to 6.6, and then process the obtained solution according to the original sulfite process until 260kg of crude syrup obtained by evaporation and concentration, and then add food additives to the crude syrup Adjust the pH to 6.5 with phosphoric acid, heat to 82°C, add 5ppm polyferric sulfate, 0.3Kg sodium stearate and 0.3kg sodium dodecylsulfonate and mix evenly, then fill in an appropriate amount of fine air bubbles from the bottom of the coarse syrup tank to make Non-sugar impurities such as colloids and pigments enter the floater to be separated from the syrup, and the quality of the obtained clear syrup is significantly improved. After that, the original process is used to produce qualified white sugar.

[0029] The test data of finished white sugar are shown in Table 1.

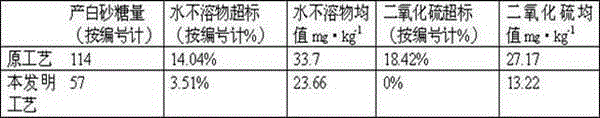

[0030] Following table 1 is the production and use effect detection data of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com