Process for preparing sugar from sugarcane

A sugarcane and process technology, applied in the field of refined sugar, can solve the problems of unavoidable and complex components, and achieve the effects of speeding up the sugar making process, good decolorization effect, and shortening the duration of the enzymatic hydrolysis process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

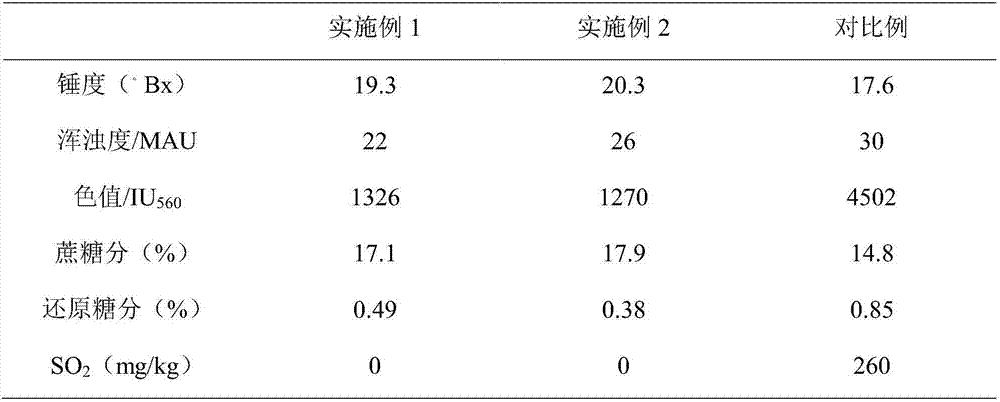

Examples

Embodiment 1

[0024] A sugar cane sugar production process, comprising the following steps:

[0025] Step 1, cleaning, chopping, squeezing and filtering the sugarcane to obtain bagasse and sugarcane juice;

[0026] Step 2. Transfer the bagasse to a temperature of 100°C and a steam pressure of 1-2 MPa for steam explosion. The steam explosion time is less than 0.01s, and the pressure holding time is 1min. After that, the pressure is released to normal pressure every 15s. The total weight of the bagasse released to normal pressure for the first time is 25%, and the bagasse after steam explosion is collected;

[0027] Step 3: Spray the compound enzyme solution on the surface of the bagasse after steam explosion, soak the surface until dripping, keep it for 10 minutes, then mix the sugarcane juice, squeeze and filter to obtain the enzymatic solution, wherein the quality of the compound enzyme solution Fraction 0.8%, the compound enzyme is a mixture of glucosidase, trypsin, amylase, and pectinas...

Embodiment 2

[0033] A sugar cane sugar production process, comprising the following steps:

[0034] Step 1, cleaning, chopping, squeezing and filtering the sugarcane to obtain bagasse and sugarcane juice;

[0035] Step 2. Transfer the bagasse to a temperature of 100°C and a steam pressure of 1-2 MPa for steam explosion. The steam explosion time is less than 0.01s, and the pressure holding time is 1min. After that, the pressure is released to normal pressure every 15s. The total weight of the bagasse released to normal pressure for the first time is 25%, and the bagasse after steam explosion is collected;

[0036] Step 3, soak the bagasse after steam explosion in ethanol solution for 6 hours, the concentration of ethanol solution is 75wt.%, the amount of ethanol solution added is enough to cover the surface of bagasse, and then press and filter, repeat 3 times, Merge the filter residue and filtrate separately, and the filtrate is ready for use, spray the compound enzyme solution on the sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com