Surface treatment liquid for zinc-aluminum-magnesium alloy steel plate as well as preparation method and use method of surface treatment liquid

A surface treatment liquid, zinc-aluminum-magnesium technology, applied in metal material coating process, coating, polyurea/polyurethane coatings, etc., can solve the problem that the quality of silane coupling agent products cannot be guaranteed, and there is no excellent blackening resistance. Environmental protection surface coating and other issues to achieve the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

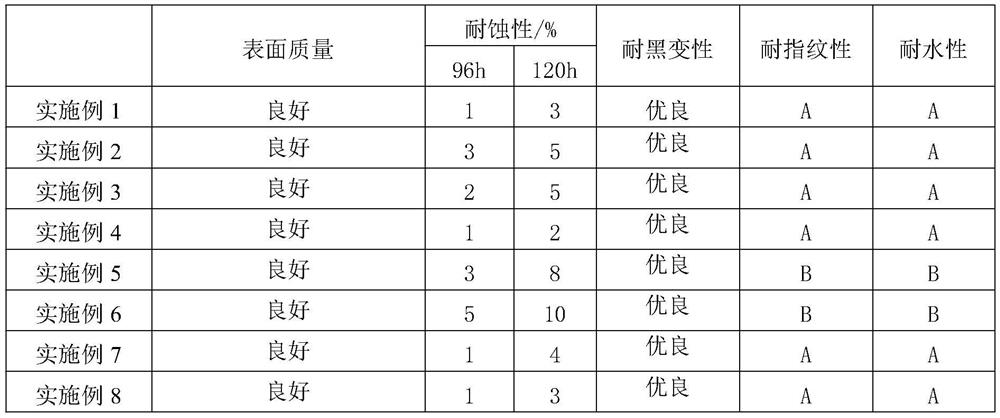

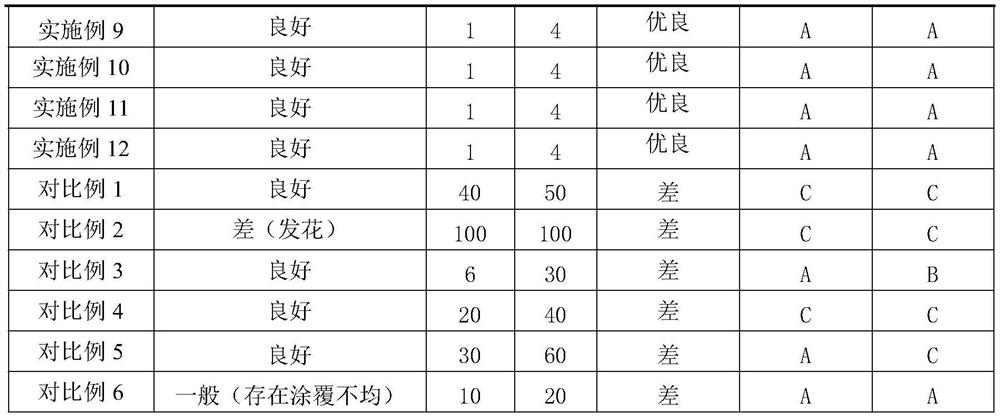

Examples

preparation example Construction

[0025] 1. Preparation method and application method of zinc-aluminum-magnesium alloy steel plate surface treatment liquid

[0026] 1. Preparation method of zinc-aluminum-magnesium alloy steel plate surface treatment liquid

[0027] Weigh each component according to the content of each component in the zinc-aluminum-magnesium alloy steel plate surface treatment solution in Table 1, dissolve the alkaline corrosion inhibitor and zirconium salt in water, then add the silane coupling agent, then add the aqueous organic emulsion, and wait until After hydrolysis is completed, add water-based lubricant, and finally add surfactant, stir for 30 minutes and leave it alone.

[0028] 2. How to use surface treatment liquid for zinc-aluminum-magnesium alloy steel sheet

[0029] Roll coating the prepared zinc-aluminum-magnesium alloy steel sheet surface treatment solution on 1.5%Al-1.5%Mg-Zn hot-dip galvanized aluminum-magnesium alloy coated steel sheet respectively, and solidify at 90°C for...

Embodiment 7

[0035] In Example 7, different from Example 1, the silane coupling agent is 3-aminopropyltriethoxysilane.

Embodiment 8

[0036] In Example 8, different from Example 1, the alkaline corrosion inhibitor is sodium metavanadate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com