Method of preparing nano-zirconia-doped tungsten oxide

A nano-zirconia and tungsten oxide technology, applied in the field of powder metallurgy, can solve the problems of coarse grains of tungsten alloys, and achieve the effects of uniform distribution of powder particles, solving coarse grains and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

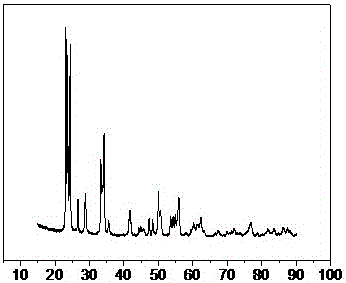

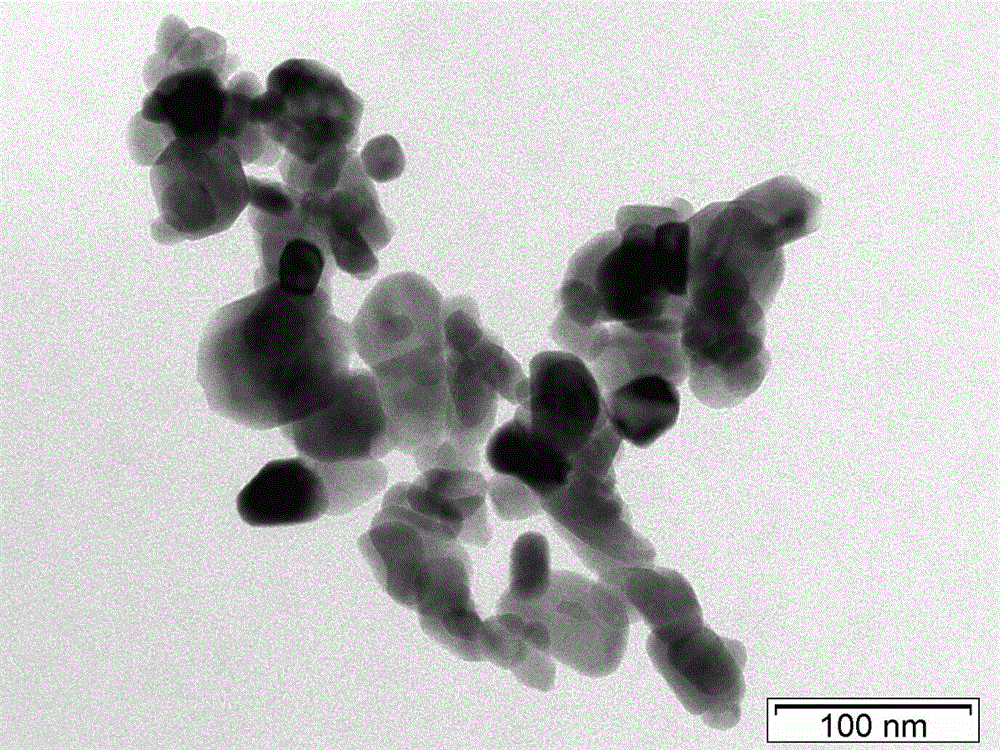

Image

Examples

Embodiment 1

[0028] A method for preparing nano zirconia doped tungsten oxide, comprising the following steps:

[0029] Step 1. At room temperature, prepare an aqueous distilled water solution of ammonium metatungstate with a molar concentration of 0.09mol / L, and under continuous stirring conditions, add concentrated nitric acid solution drop by drop into the distilled water solution of ammonium metatungstate until the solution The pH value reaches 0.1-1.5, for later use;

[0030] Step 2, at room temperature, prepare the mixed distilled water aqueous solution of zirconium nitrate and urea according to the mol ratio of zirconium nitrate and urea is 0.3:1, standby;

[0031] Step 3. According to the molar ratio of ammonium metatungstate, zirconium nitrate and urea is 2.80:0.3:1, add the solutions prepared in step 1 and step 2 into the autoclave respectively, and react at 170°C for 18 hours. After the reaction is complete , take out and air cool to room temperature;

[0032] Step 4. Pour out...

Embodiment 2

[0036] A method for preparing nano zirconia doped tungsten oxide, comprising the following steps:

[0037] Step 1. At room temperature, prepare an aqueous distilled water solution of ammonium metatungstate with a molar concentration of 0.15mol / L, and add concentrated nitric acid solution drop by drop into the distilled water solution of ammonium metatungstate until the solution is pH value reaches 1.5, standby;

[0038] Step 2, at room temperature, prepare the mixed distilled water aqueous solution of zirconium nitrate and urea according to the mol ratio of zirconium nitrate and urea as 0.5:1, standby;

[0039] Step 3. According to the molar ratio of ammonium metatungstate, zirconium nitrate and urea is 2.77:0.5:1, add the solutions prepared in step 1 and step 2 into the autoclave respectively, and react at 200°C for 24 hours. After the reaction is complete , take out and air cool to room temperature;

[0040] Step 4, pour out the supernatant of the solution obtained in step...

Embodiment 3

[0044] A method for preparing nano zirconia doped tungsten oxide, comprising the following steps:

[0045] Step 1. At room temperature, prepare an aqueous distilled water solution of ammonium metatungstate with a molar concentration of 0.12mol / L, and add concentrated nitric acid solution drop by drop into the distilled water solution of ammonium metatungstate until the solution is pH value reaches 0.8, standby;

[0046] Step 2, at room temperature, prepare the mixed distilled water aqueous solution of zirconium nitrate and urea according to the mol ratio of zirconium nitrate and urea as 0.05:1, standby;

[0047] Step 3. According to the molar ratio of ammonium metatungstate, zirconium nitrate and urea is 0.25:0.05:1, add the solutions prepared in step 1 and step 2 into the autoclave respectively, and react at 185°C for 21 hours. After the reaction is complete , take out and air cool to room temperature;

[0048] Step 4. Pour out the supernatant of the solution obtained in st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com