A kind of preparation method and application of refiner

A refiner and compression molding technology, which is applied in the field of precision casting, can solve problems such as casting quality decline, and achieve the effect of improving quality and performance, and strong operability

Active Publication Date: 2022-05-31

INST OF METAL RESEARCH - CHINESE ACAD OF SCI

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

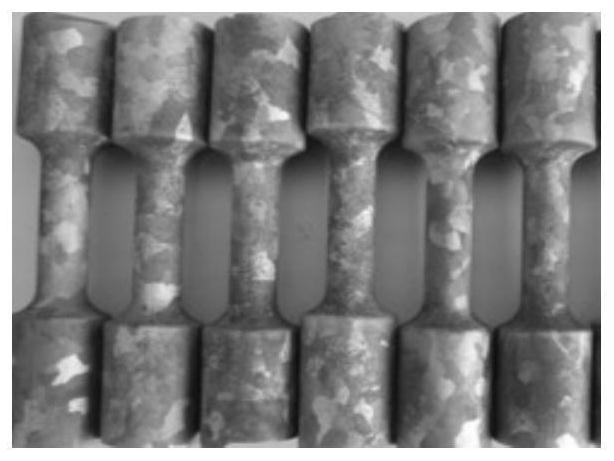

The invention relates to the technical field of precision casting, in particular to a preparation method and application of a refiner. Select Ni, Al, WC, Co and other powders according to a certain mass percentage and particle size requirements, and mix them into powder. The cold isostatic pressing technology is used to press and form at room temperature and a pressure of 10-60 MPa; the refiner is ultrasonically cleaned with alcohol and dried at a temperature of 50-100 °C. When pouring at the end, add refiner, and at the same time ensure that the temperature of the alloy liquid is within the range of 1500-1750°C, the pouring time is 10-120 seconds, the holding time is 1-3 minutes, the addition amount is 0.01-0.5wt%, and argon is blown into the pouring chamber Gas, stir with a corundum rod, and observe the grain size of the sample after cooling. The invention is applicable to the casting process of all metal materials, can effectively solve the problem of quality reduction of castings caused by coarse high-temperature alloy crystal grains, has simple operation, low cost, high economic benefits and long-term application prospects.

Description

A kind of preparation method and application of refiner technical field The present invention relates to precision casting technical field, be specifically a kind of preparation method and application of refiner. Background technique Ordinary polycrystalline casting superalloys still have a wide range of applications in modern aerospace engines and industrial gas turbines. The cast superalloys used, especially at low and medium temperatures, are basically in the polycrystalline state. In ordinary investment casting The polycrystalline superalloy castings produced under the conditions are relatively coarse dendrites or columnar crystals, which lead to the reduction of the mechanical properties of the castings. Affect the work efficiency of key components such as engines and gas turbines. SUMMARY OF THE INVENTION The object of the present invention is to provide a kind of preparation method and application of refiner, be applicable to the casting of all metal materi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B22D1/00C22C1/06C22C1/05C22C1/10C22C19/03C22C19/07

CPCB22D1/00C22C1/06C22C1/05C22C19/07C22C19/03

Inventor 杨金侠李雪徐福涛王志辉孟杰周亦胄孙晓峰

Owner INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com