Preparation method and application of refiner

A refiner, press molding technology, applied in the field of precision casting, can solve the problem of quality decline of castings, achieve the effect of improving quality and performance, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In the present embodiment, the preparation method of the refiner is as follows:

[0025] Take Ni, Al, WC, Co and other powders, the mass percentages are 30%, 10%, 9% respectively, Co is the balance; the particle size is Ni (200 mesh), Al (320 mesh), WC (100 mesh), Co (80 mesh), mixed into powder; adopt cold isostatic pressing technology at room temperature and pressure 32MPa; use alcohol to ultrasonically clean the refiner, and dry at 100°C.

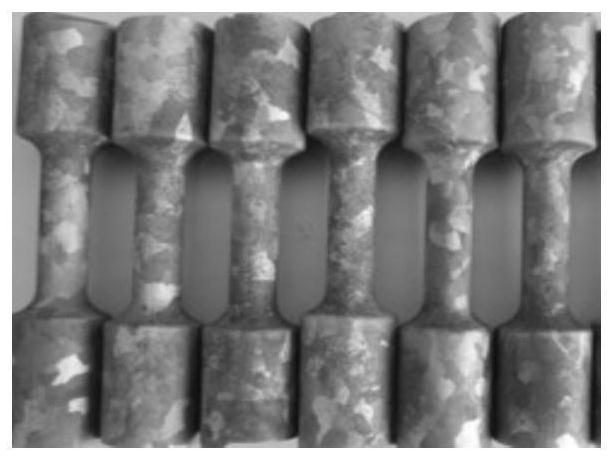

[0026] Casting I-shaped sample, the alloy grade is In-792, adding refiner, the temperature of the alloy liquid is 1750 °C, the pouring time is 100 seconds, the heat preservation is 1 minute, and the addition amount is 0.02% of the weight of the alloy liquid; at the same time, pouring Blow argon in the room for 30 seconds, and stir with a corundum rod for 1 minute, and observe the grain size of the sample after cooling. figure 1 and figure 2 is the surface grain size and section grain size of the sample without adding refiner; ...

Embodiment 2

[0028] In the present embodiment, the preparation method of the refiner is as follows:

[0029] Take Ni, Al, WC, Co and other powders, the mass percentages are 50%, 30%, 8% respectively, Co is the balance; the particle size is Ni (320 mesh), Al (200 mesh), WC (80 mesh), Co (100 mesh) is mixed and mixed into powder; cold isostatic pressing technology is used to press at room temperature and pressure 38MPa; the refiner is ultrasonically cleaned with alcohol and dried at 60°C.

[0030] Pouring I-shaped sample, its alloy grade is K418b, adding refiner, at this time, the temperature of the alloy liquid is 1550°C, the pouring time is 60 seconds, the heat preservation is 2 minutes, and the addition amount is 0.09% of the weight of the alloy liquid; at the same time, pouring Blow argon in the room for 65 seconds, and stir with a corundum rod for 1 minute, and observe the grain size after cooling. Figure 5 It can be seen that the crystal grains are also obviously refined.

[0031] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com