Method for synthesizing mesoporous gamma-Al2O3 by anion/cation dual-hydrolysis

An anion-cation and double hydrolysis technology, which is applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, can solve the problems of long production cycle, harsh reaction conditions, and high price, and achieve good hydrothermal stability, Rapid hydrolysis reaction and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

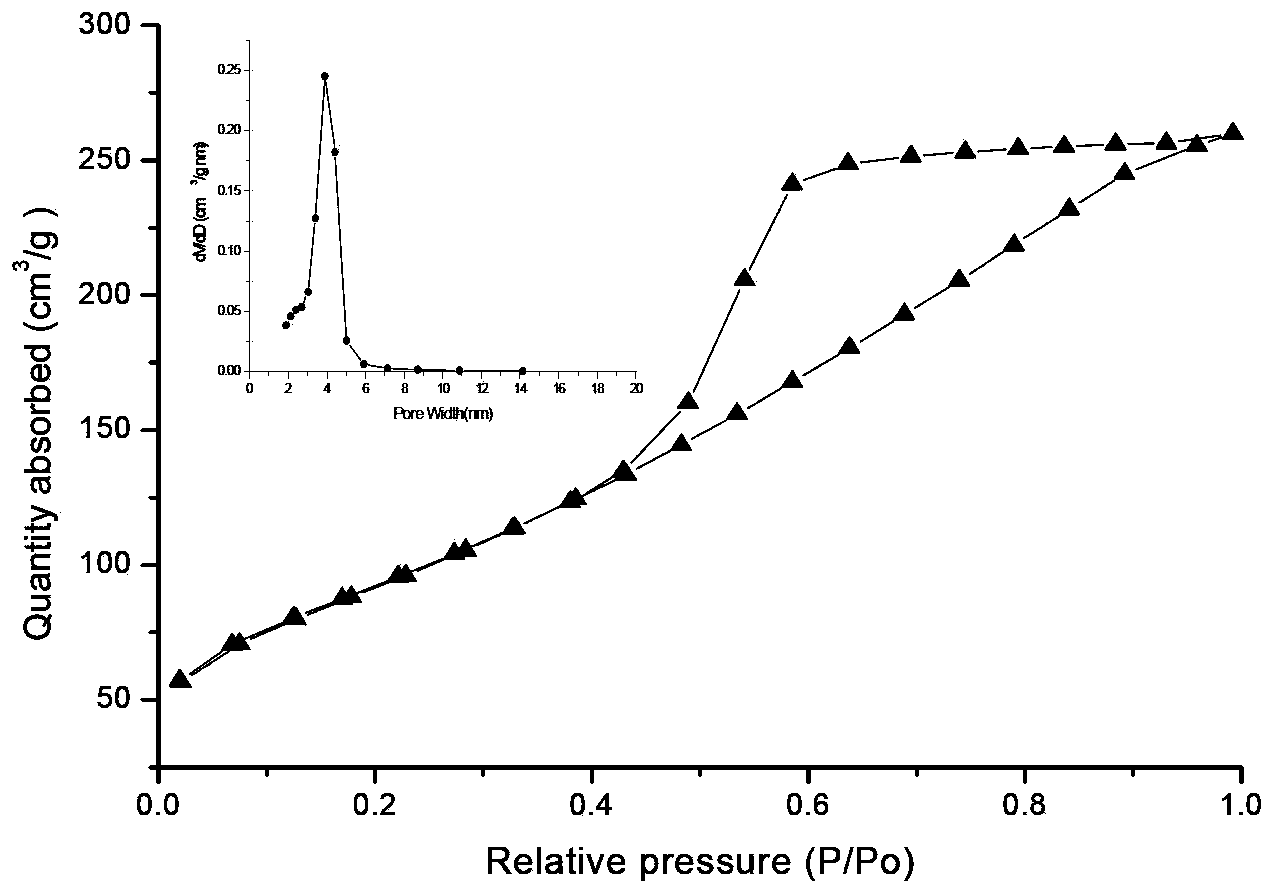

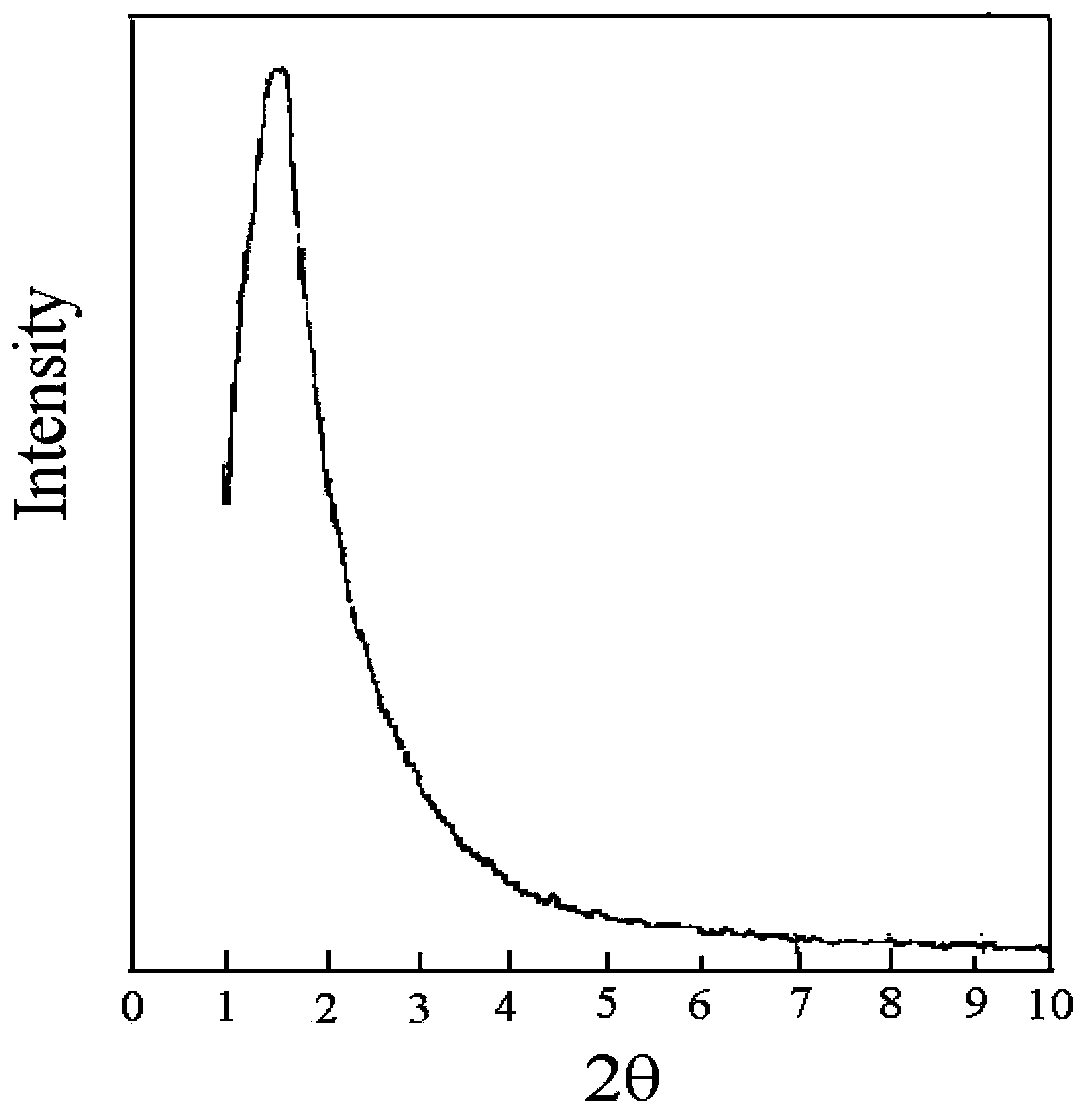

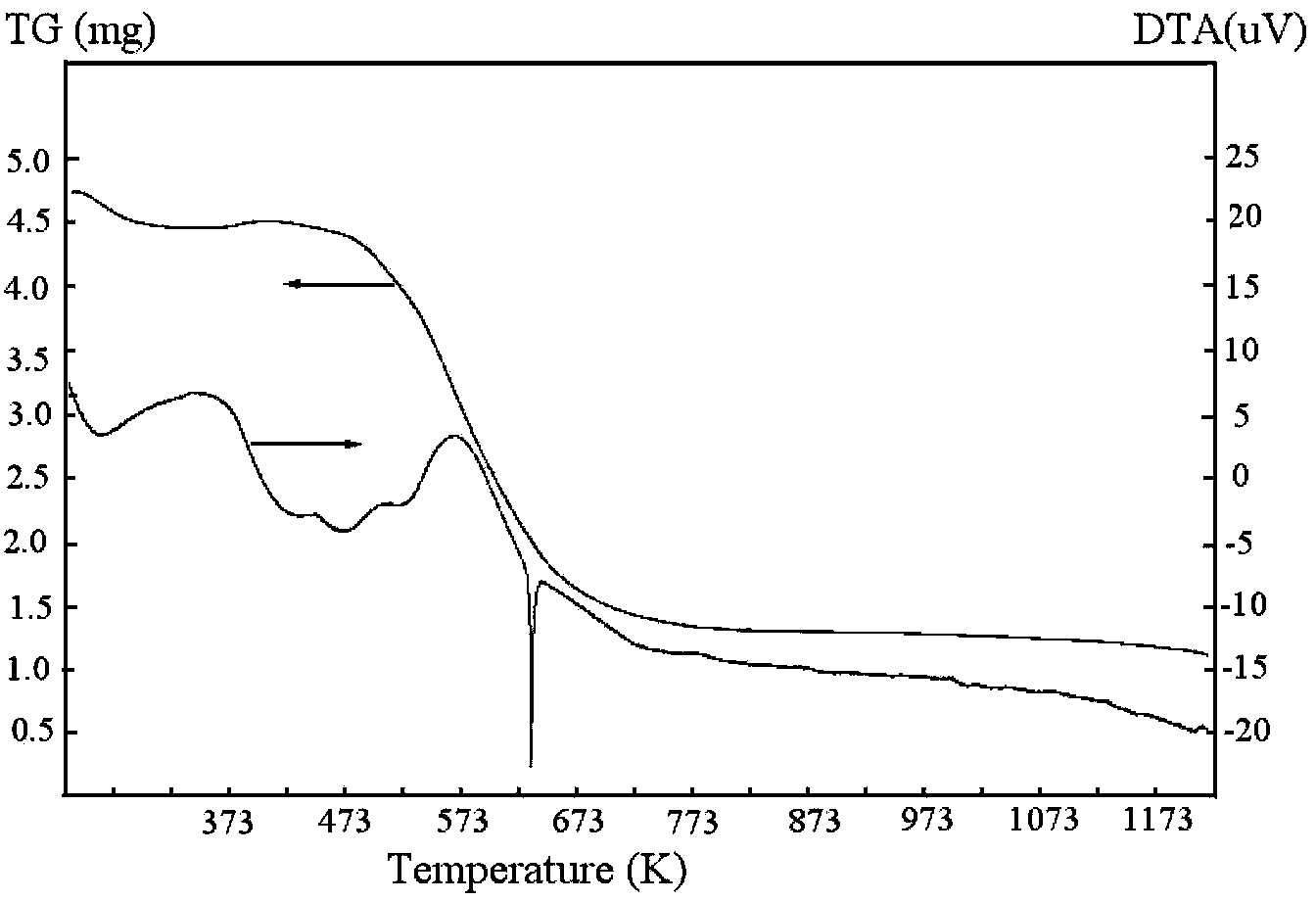

[0042] Under vigorous stirring, a certain amount of NaAlO 2 Solution (4.71wt%Al 2 o 3 ,2.87wt%Na 2 O) was added dropwise to Al(NO 3 ) 3 and P123 mixed aqueous solution (10.3wt%Al(NO 3 ) 3 ,7.7wt%P123), after stirring at room temperature for 4 hours, the molar composition of Al(NO 3 ) 3 9H 2 O:3NaAlO 2 :0.05P123:278H 2 O mixture, the reaction mixture was allowed to stand at room temperature for 24 hours, then transferred to a stainless steel reactor, crystallized at 80°C for 24 hours, taken out, filtered with suction, washed to remove floating matter on the surface. Dry at 80°C to obtain an organic-inorganic composite, which is then fired at 150°C for 6 hours, and then fired at 500°C for 4 hours to obtain mesoporous alumina. Representative N 2 Adsorption-desorption isotherm, XRD, TG-DTA curve as Figure 1~4 shown.

Embodiment 2

[0044] Under vigorous stirring, a certain amount of Al(NO 3 ) 3 solution (15.79 wt%) was added dropwise to NaAlO 2 and a mixed aqueous solution of P123 (4.44wt% Al 2 o 3 ,8.02wt%P123,2.63wt%Na 2 O), after stirring at room temperature for 4 hours, the molar composition of Al(NO 3 ) 3 9H 2 O:3NaAlO 2 :0.05P123:278H 2 O mixture. Other conditions are the same as example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com