Sulfur fumigation neutralizer and method for sulfur fumigation neutralization reaction by the same

A technology of sulfur fumigation and sugarcane juice, which is applied in the direction of purification with alkaline earth compounds and purification with oxidation/reduction, etc., can solve the problem of residual sulfur dioxide in white sugar, and achieve the effect of saving sulfur consumption, solid particles, and uniform particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with specific embodiment, but protection scope of the present invention is not limited to following embodiment:

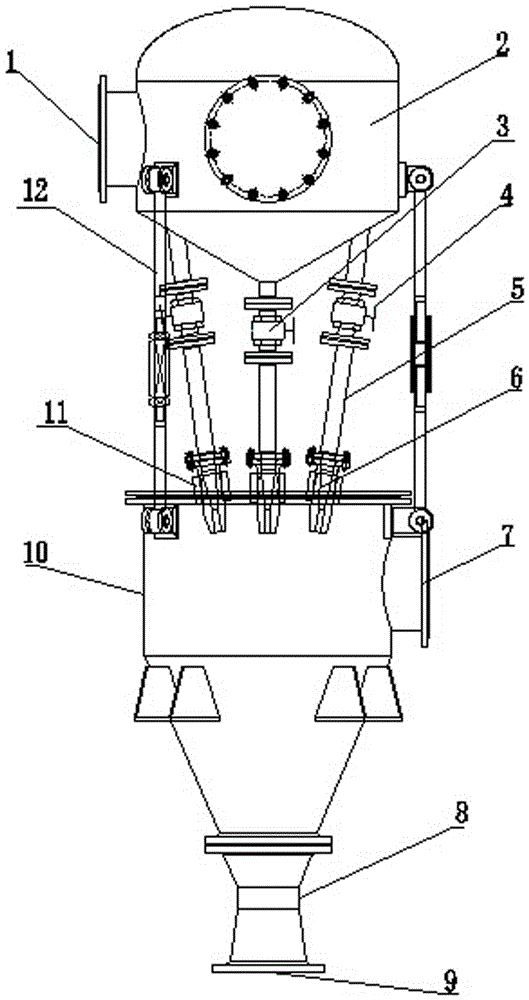

[0034] Such as figure 1 As shown, a sulfur fumigation neutralizer includes a juice chamber 2 and a suction chamber 10. The side of the juice chamber 2 is provided with a juice inlet nozzle 1, and the bottom of the juice chamber 2 is provided with a suction chamber 10. The suction chamber 10 One side is provided with sulfur dioxide gas pipe port 7, and the bottom of suction chamber 10 is communicated in the neutralization reaction box through throat pipe 8, tailpipe 9 and reaction tube successively, and reaction tube and neutralization reaction box are not shown in the figure.

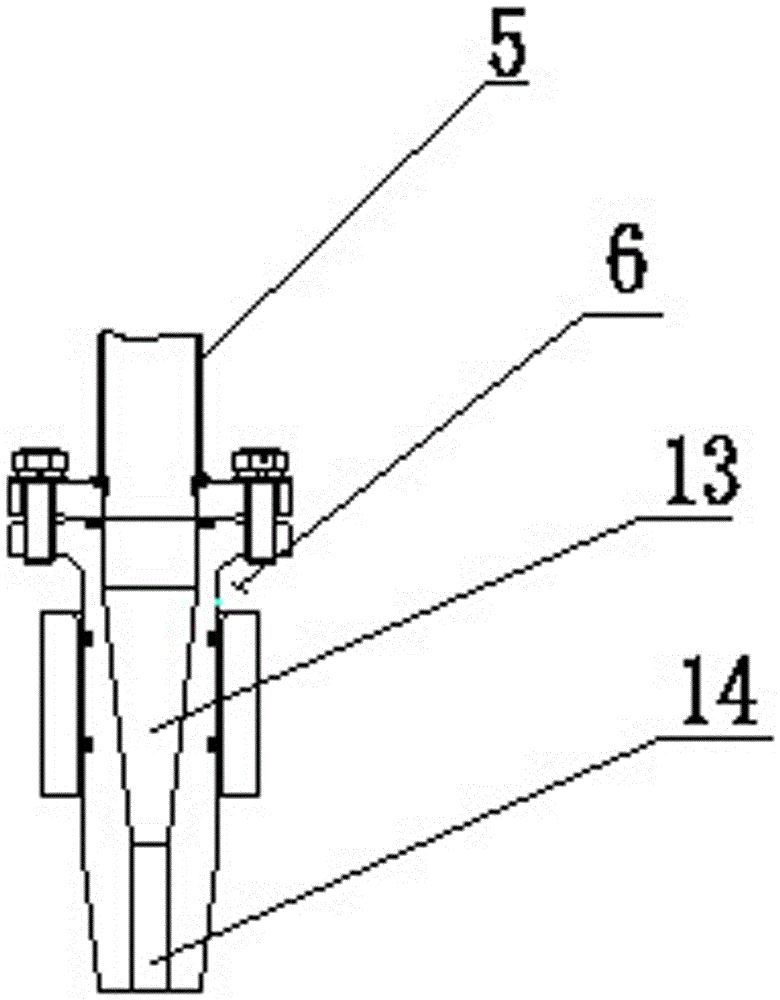

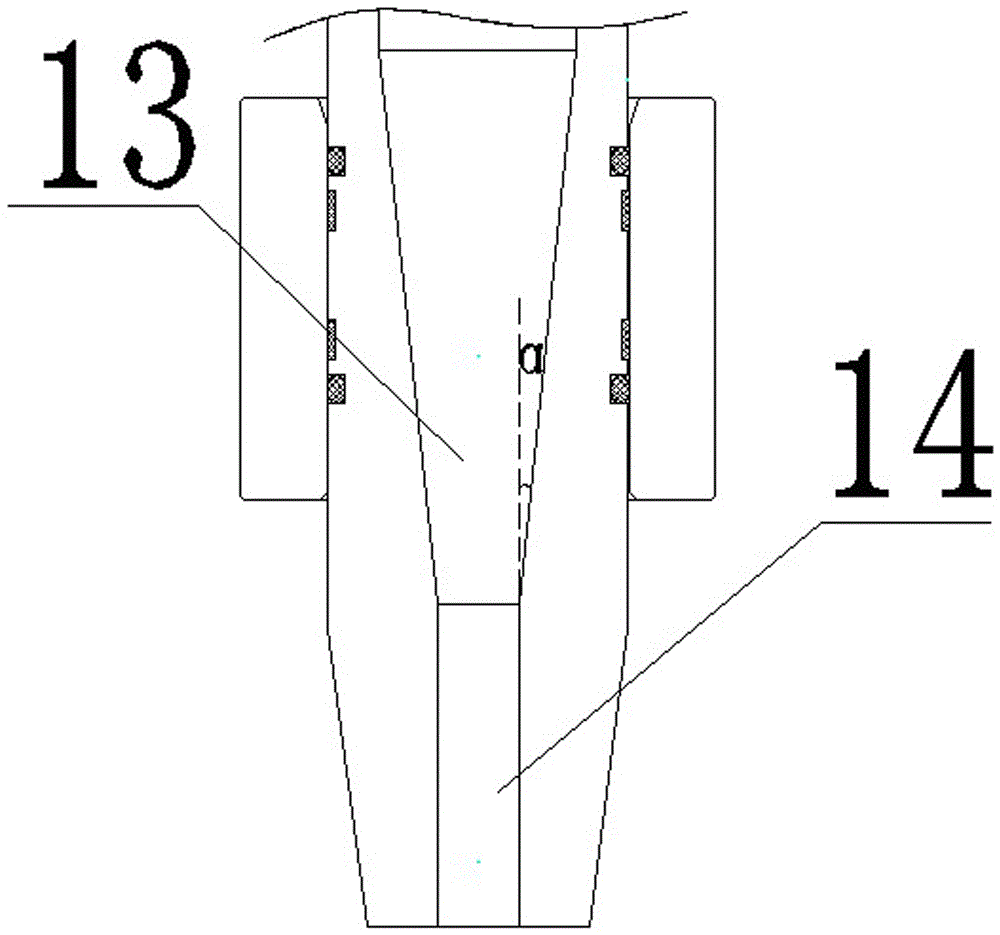

[0035] Between the juice chamber 2 and the suction chamber 10, 3 to 10 cane juice guide tubes 5 are installed at intervals, the upper end of the sugarcane juice guide tube 5 is connected to the juice chamber 2, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com