Stoving neutral reaction system

A reaction system and sulfur fumigation technology, applied in the field of sugar cane sugar production, can solve the problems of increasing sulfur production cost and gas, and achieve the effects of reducing the amount of sulfur, reducing environmental pollution, and increasing the contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

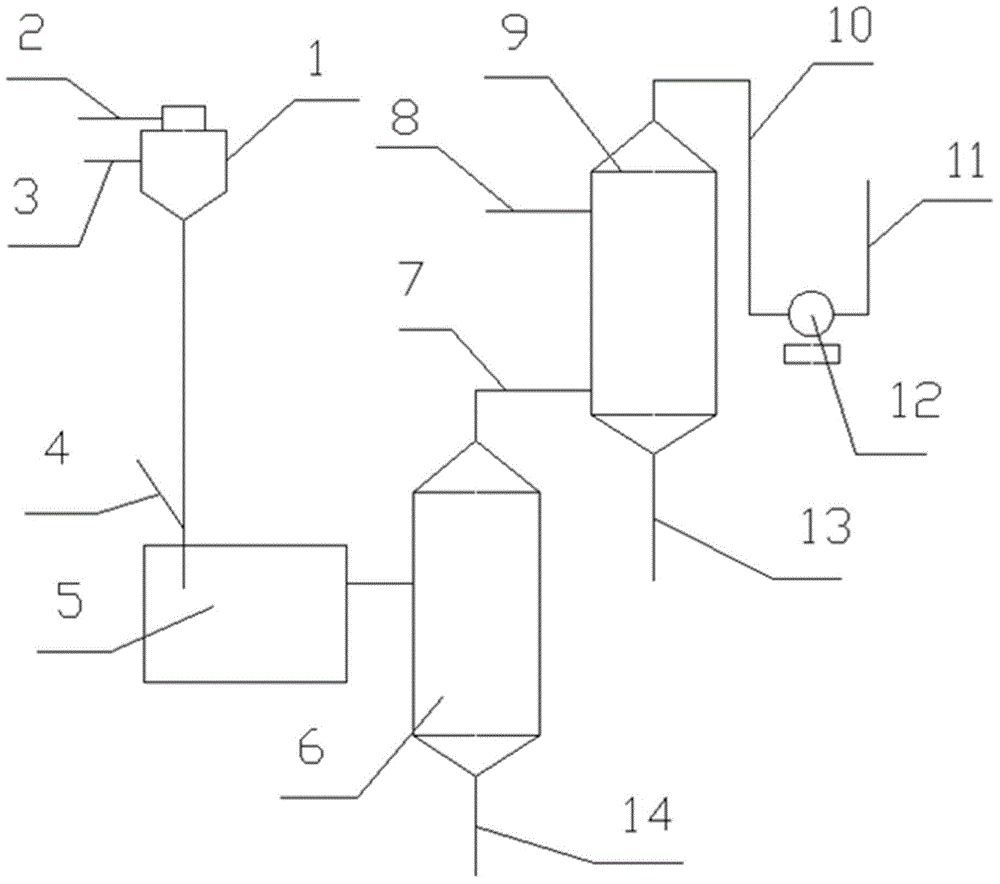

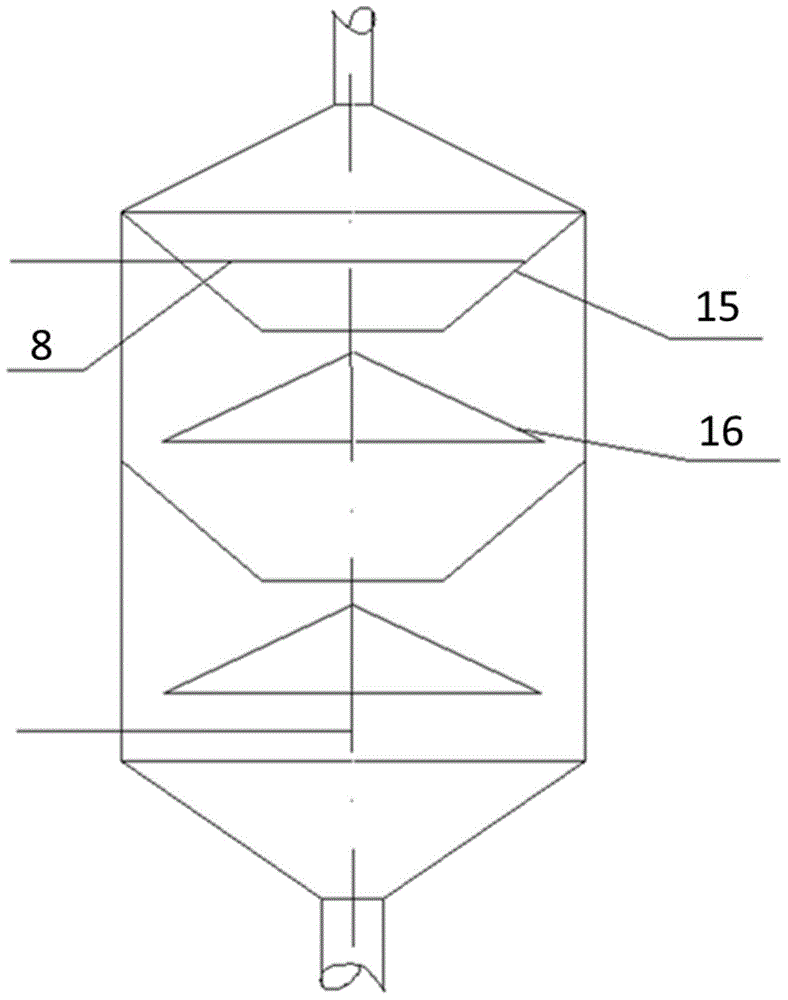

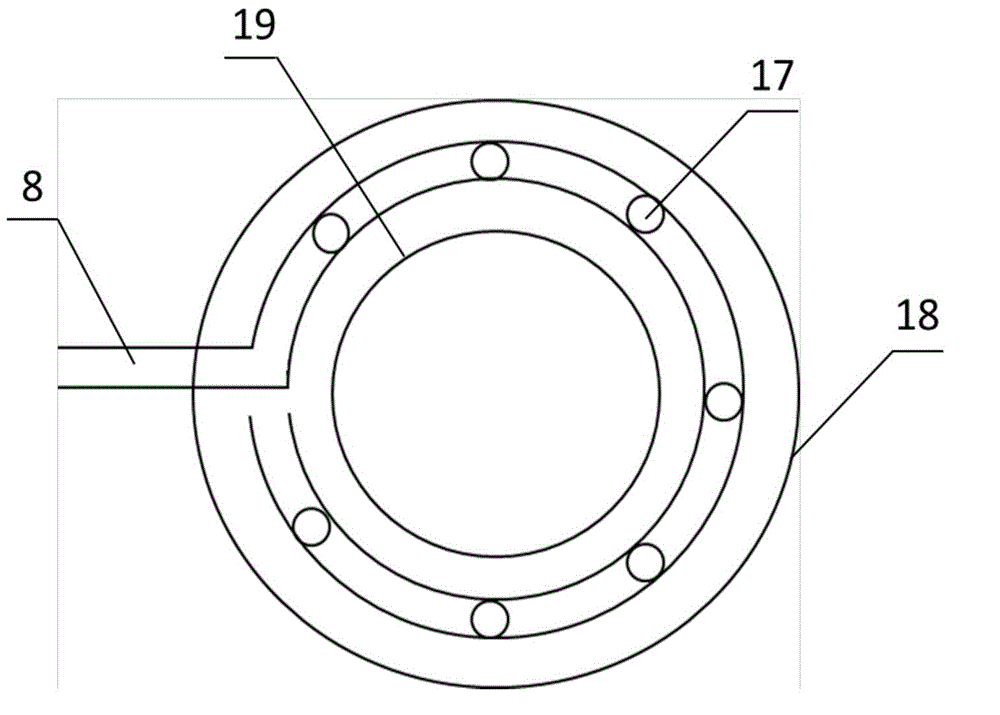

[0029] See figure 1 with figure 2 As shown, the embodiment of the present invention provides a sulfur fumigation neutralization reaction system, the system includes a sulfur fumigation neutralizer 1, a reaction tank 5 and an air diffuser tank 6, and the reaction tank 5 is connected with the sulfur fumigation tube 4 through the lime milk tube 4. The smoke neutralizer 1 is connected, the gas diffuser barrel 6 is connected with the reaction barrel 5 through a pipeline, and the sulfur smoke neutralizer 1 is provided with the first cane juice injection pipe 2 and the SO 2 Injection pipe 3, the first juice discharge pipe 14 is arranged on the lower part of the air diffuser barrel 6, and the system also includes an absorption tower 9, which is connected to the air diffuser barrel 6 through an exhaust pipe 7, and the absorption tower 9 is also A second sugarcane juice injection pipe 8 is provided, and a second juice discharge pipe 13 is arranged at the bottom of the absorption tower...

Embodiment 2

[0041] See figure 1 with figure 2 As shown, the embodiment of the present invention provides a sulfur fumigation neutralization reaction system, the system includes a sulfur fumigation neutralizer 1, a reaction tank 5 and an air diffuser tank 6, and the reaction tank 5 is connected with the sulfur fumigation tube 4 through the lime milk tube 4. The smoke neutralizer 1 is connected, the gas diffuser barrel 6 is connected with the reaction barrel 5 through a pipeline, and the sulfur smoke neutralizer 1 is provided with the first cane juice injection pipe 2 and the SO 2 Injection pipe 3, the first juice discharge pipe 14 is arranged on the lower part of the air diffuser barrel 6, and the system also includes an absorption tower 9, which is connected to the air diffuser barrel 6 through an exhaust pipe 7, and the absorption tower 9 is also A second sugarcane juice injection pipe 8 is provided, and a second juice discharge pipe 13 is provided at the lower part of the absorption t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com