Method for preparing L-iditol

A technology of iditol and sorbitol, applied in the field of preparing high-purity L-iditol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

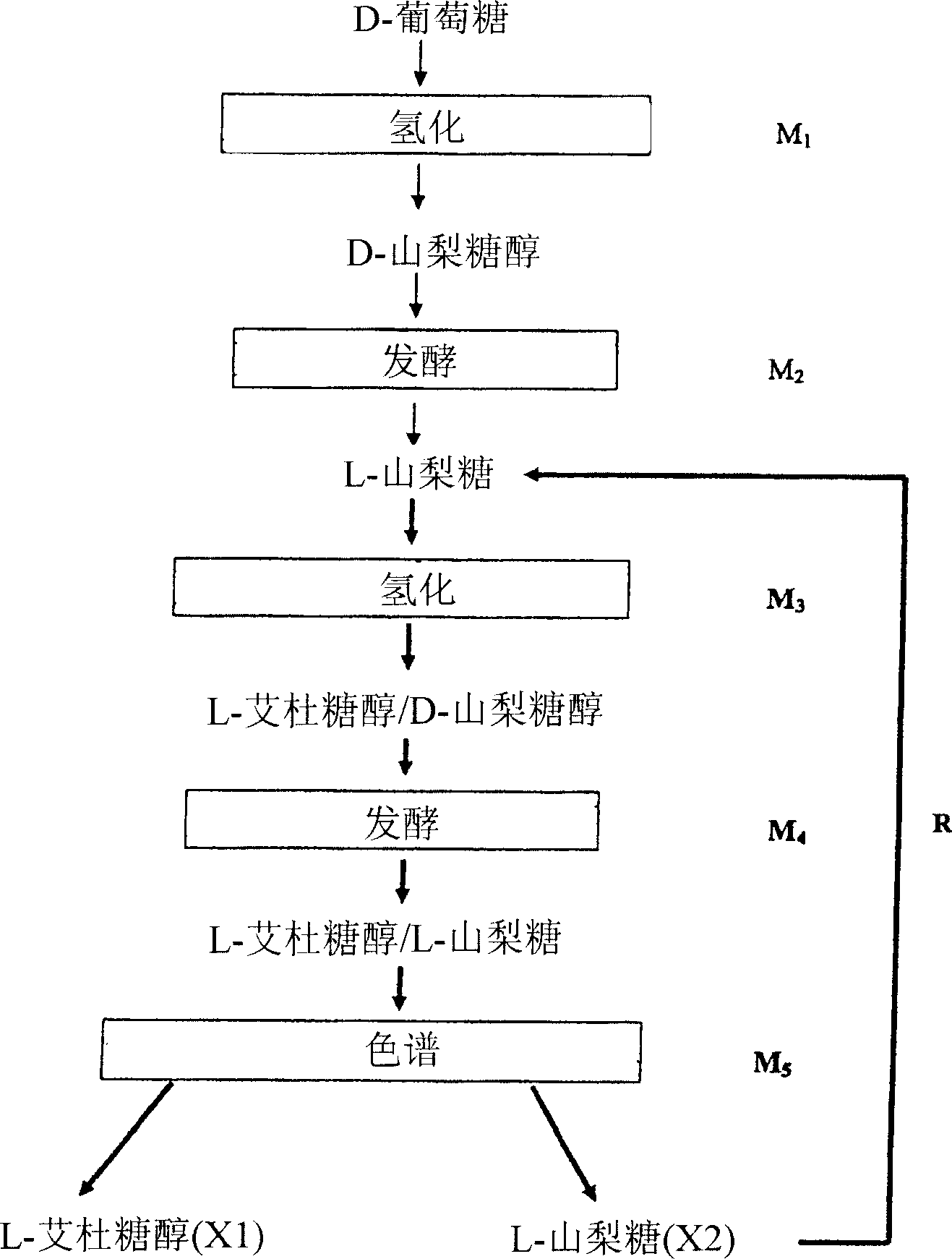

Method used

Image

Examples

Embodiment Construction

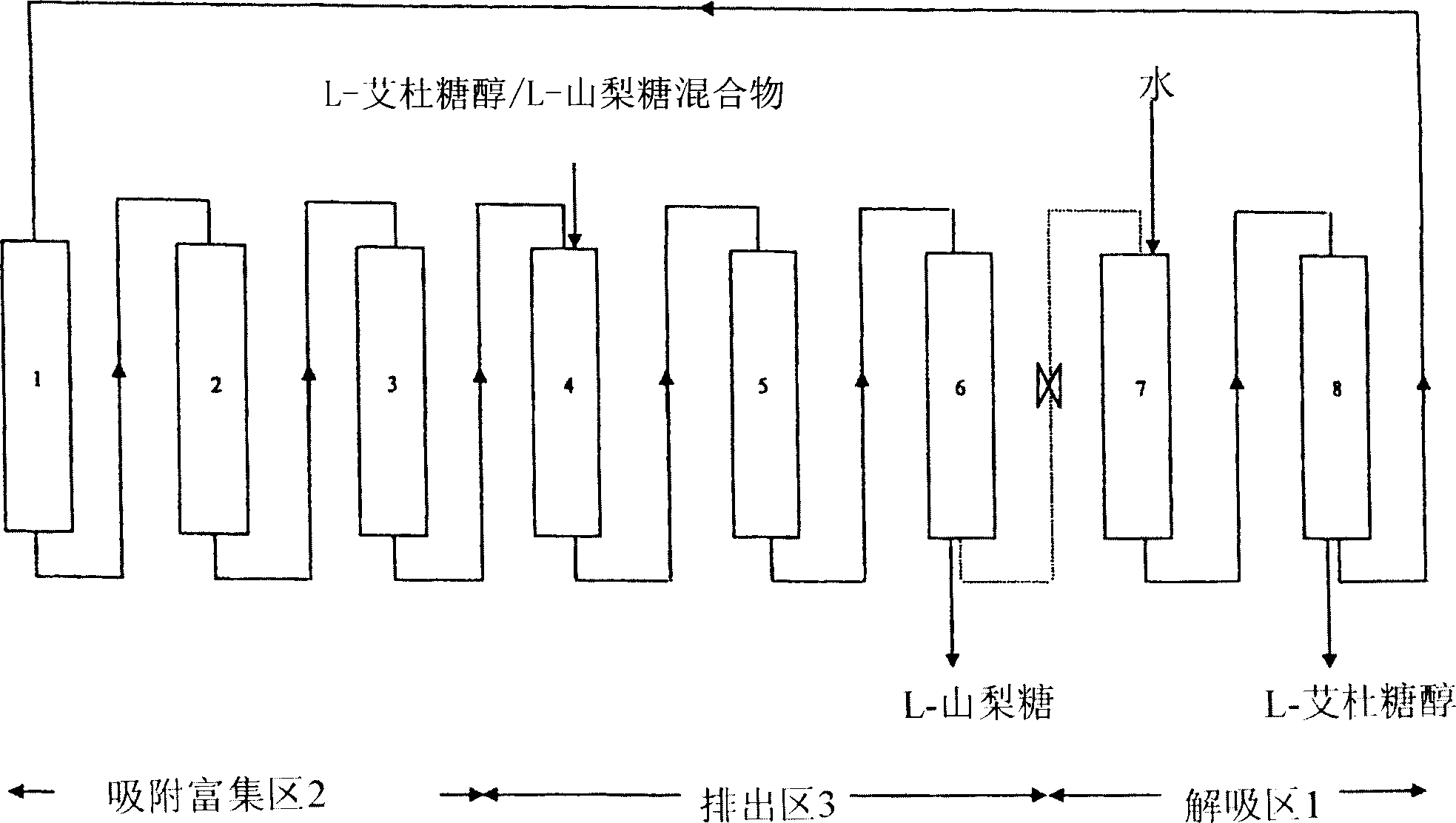

[0077] A mixture containing 45% L-sorbose and 55% L-iditol was chromatographed. In fact, this mixture contains very small amounts of other sugars and polyols, about 2%. Using Gluconobacter oxidans ATCC 19357 to ferment a mixture of D-sorbitol and L-iditol obtained by hydrogenation of a 40% L-sorbose solution and obtained. Hydrogenation using Raney nickel at substantially neutral pH yielded a slurry containing 0.2% residual reducing sugars and substantially equal amounts of D-sorbitol and L-iditol. After fermentation, the slurry was purified by filtration, then decolorized on carbon pellets, and finally desalted on ion exchange resins, followed by concentration to 50% solids.

[0078] as in US Patent 4,422,881 figure 2 As shown, the chromatographic unit contains 8 columns or stages, each of 200 liters, with a strong ionic resin-type sorbent in the form of calcium and of fine and uniform particle size (0.2-0.3mm) (PCR732 from Purolite) , the content of this patent is incorp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com