Cane juice stoving neutralization reaction control system

A reaction control system and sulfur fumigation technology, applied in the control/regulation system, multiple fluid ratio control, ratio control, etc., can solve the problems of unstable speed, difficult to control the pH value of sucrose, incomplete reaction between lime milk and SO2, etc. , to achieve the effect of rapid control process, simple operation and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

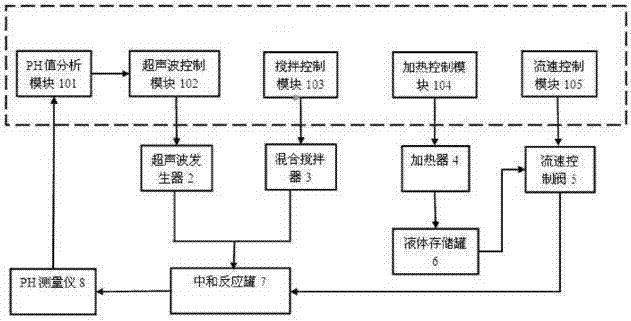

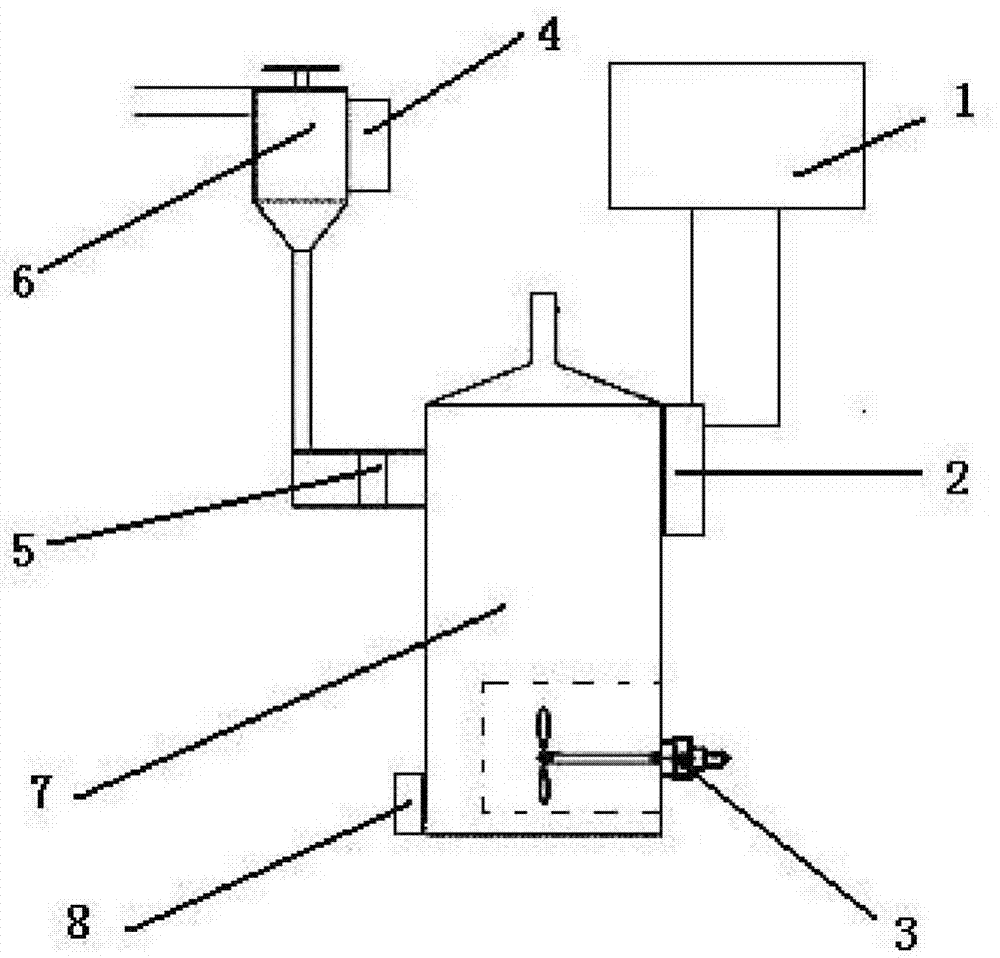

[0028] Such as figure 1 , 2 As shown, the sugarcane juice sulfur fumigation neutralization reaction control system of the present invention includes a liquid storage tank 6 and a neutralization reaction tank 7, the liquid storage tank and the neutralization reaction tank are connected by a liquid pipeline, and the pipeline is near one end of the neutralization reaction tank A flow rate control valve 5 is provided; a heater 4 is provided in the storage tank 6; an ultrasonic generator 2, a mixing agitator 3 and a pH measuring instrument 8 are matched in the neutralization reaction tank 7; The control board 1 that controls the progress of the neutralization reaction in a feedback adjustment manner, the control board includes a pH value analysis module 101 , an ultrasonic control module 102 , a stirring control module 103 , a heating control module 104 and a flow rate control module 105 .

[0029] During the reaction process, the detection signal transmitted by the pH measuring i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com