Sugarcane juicing equipment capable of automatically classifying residues

An automatic sorting and juicing technology, which is applied in the direction of extracting juice from sugar cane, solid separation, and sieving. The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

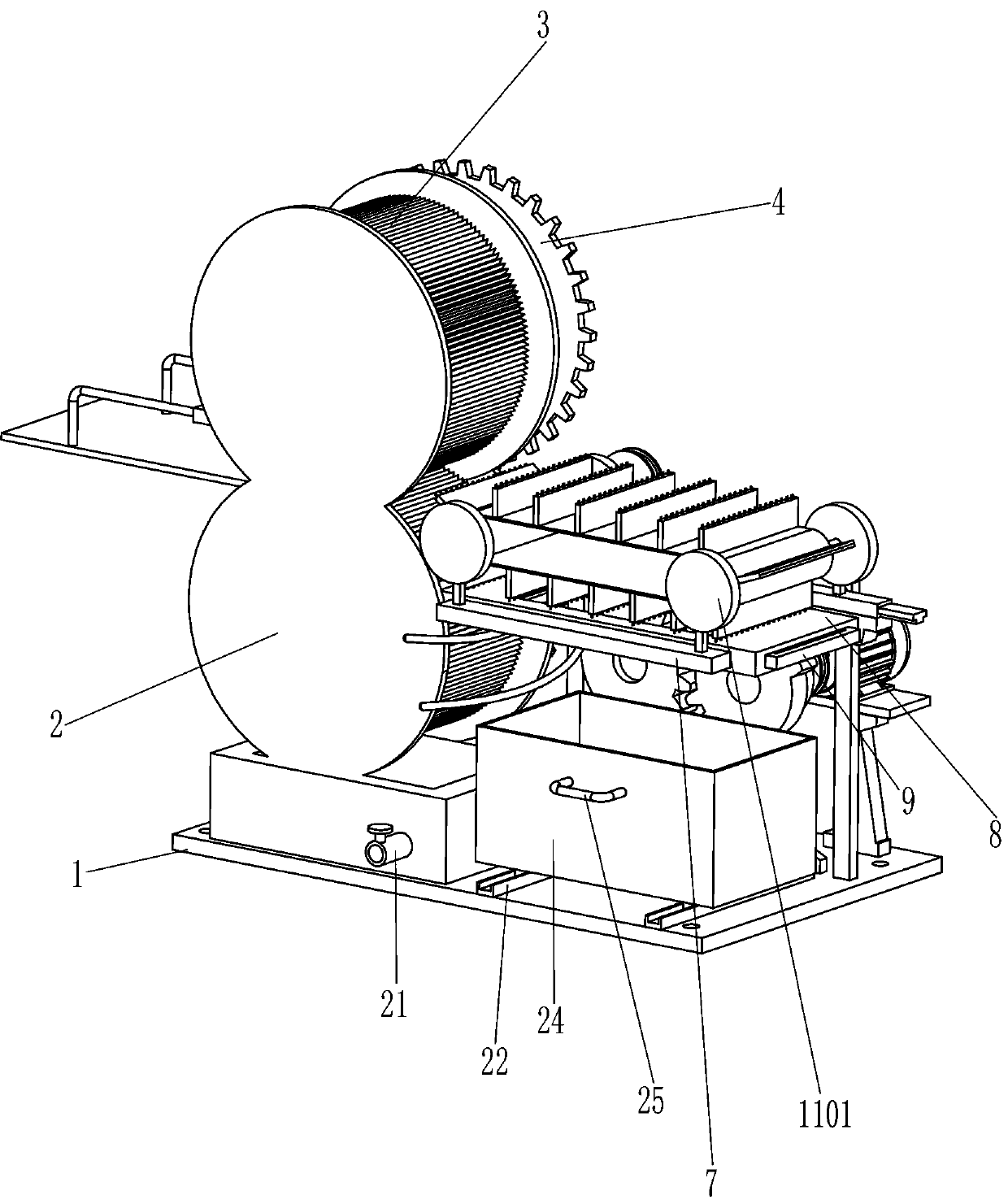

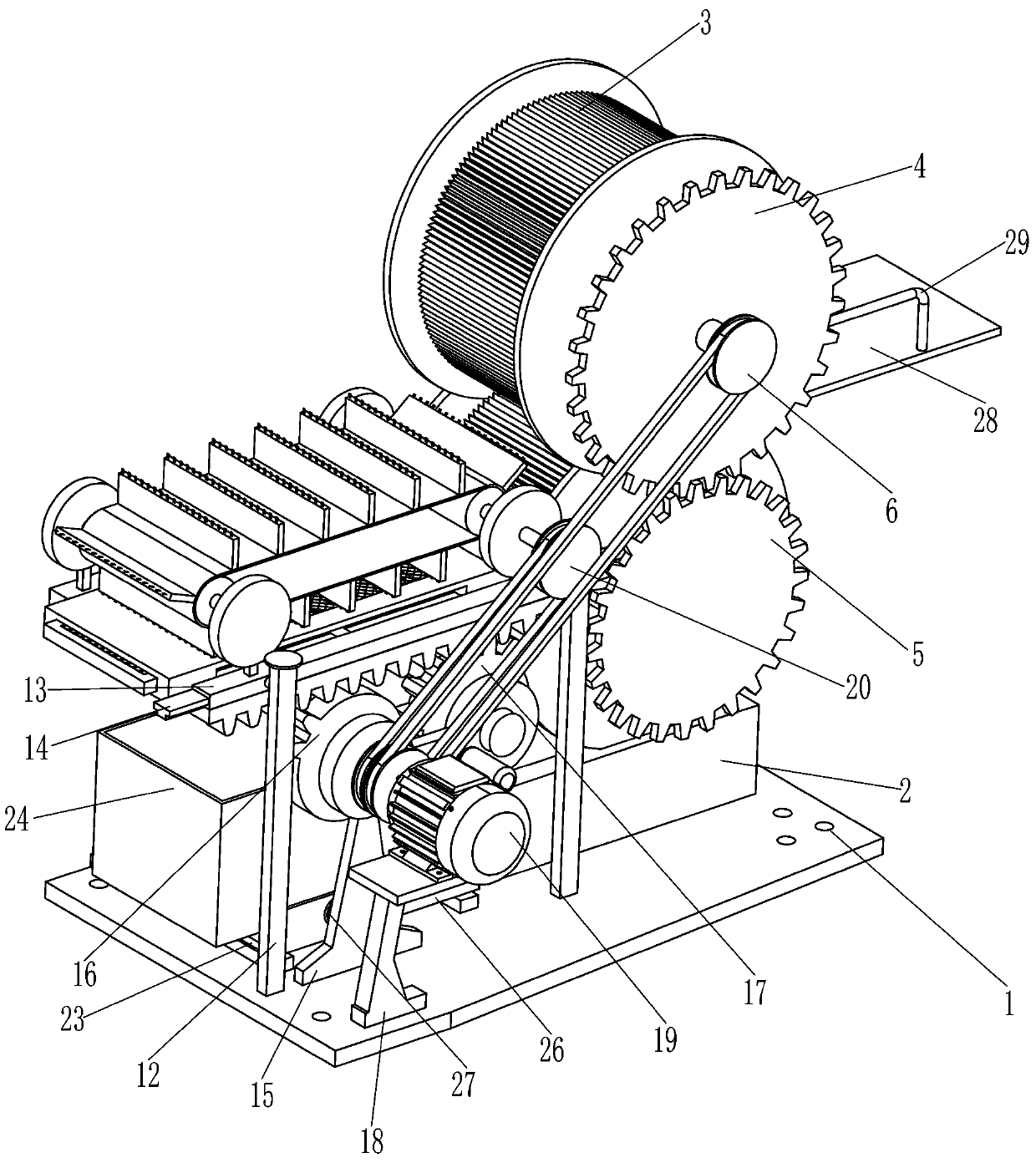

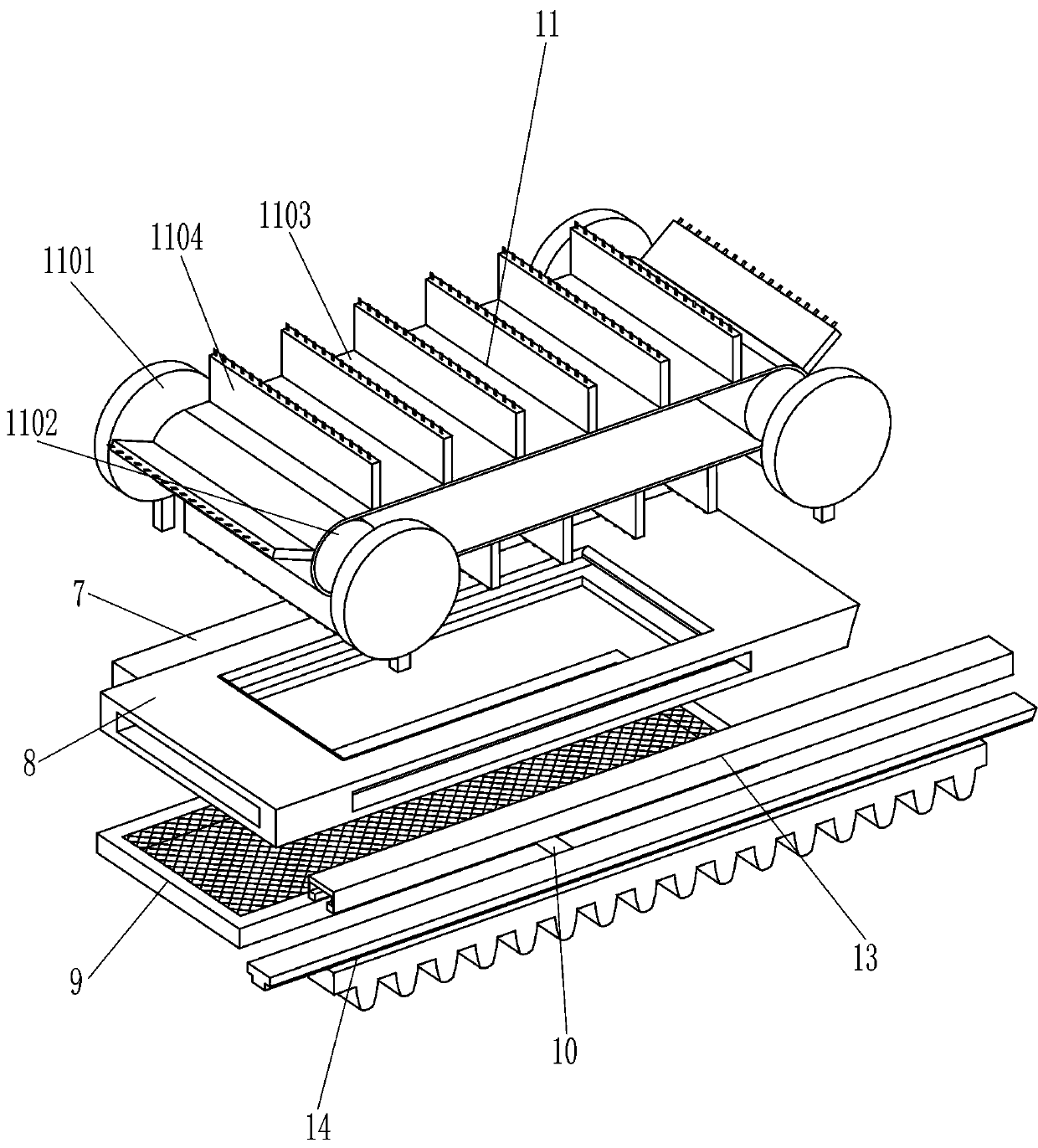

[0020] A sugarcane juicer capable of automatically sorting residues, such as Figure 1-3 As shown, it includes a base plate 1, a collection frame 2, a rolling wheel 3, a large gear 4, a pinion 5, a first transmission assembly 6, a support plate 7, a slotted plate 8, a mesh plate 9, a connecting rod 10, and a pusher Device 11, support column 12, guide rail 13, rack 14, mounting frame 15, multi-port gear 16, sector gear 17, mounting plate 18, driving motor 19, second transmission assembly 20 and drain assembly 21, bottom plate 1 top is provided with There is a collection frame 2, the upper and lower sides of the collection frame 2 are rotatably connected with rolling wheels 3, one end of the upper rolling wheel 3 is connected with a large gear 4, one end of the lower rolling wheel 3 is connected with a pinion 5, and a pinion 5 Mesh with the big gear 4, the first transmission assembly 6 is connected to one side of the big gear 4, the back side of the collection frame 2 is provide...

Embodiment 2

[0024] On the basis of Example 1, such as Figure 1-2 As shown, it also includes a guide rail 22, a guide bar 23, a receiving frame 24, a handle 25, a horizontal plate 26 and a compression spring 27. A pair of guide rails 22 are arranged on the top of the bottom plate 1, and a guide rail 22 is slidably connected with a guide rail. Bar 23, guide strip 23 tops are provided with receiving frame 24 jointly, and receiving frame 24 rear portions are provided with pull handle 25, and guide bar 23 front ends on both sides are provided with transverse plate 26 jointly, and transverse plate 26 is connected with mounting frame 15 Compression spring 27 is arranged.

[0025] Because most of the bagasse is slightly larger in volume, there is less bagasse falling into the receiving frame 24. After the equipment has squeezed sugarcane juice for many times, a large amount of bagasse is housed in the receiving frame 24 at this time, and then the workers pass through Pull handle 25 pulls out ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com