Cane sugar purification device for sugarcane processing

A technology of sucrose and sugarcane, which is applied in the field of sucrose purification devices for sugarcane processing, and can solve problems such as insufficient integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

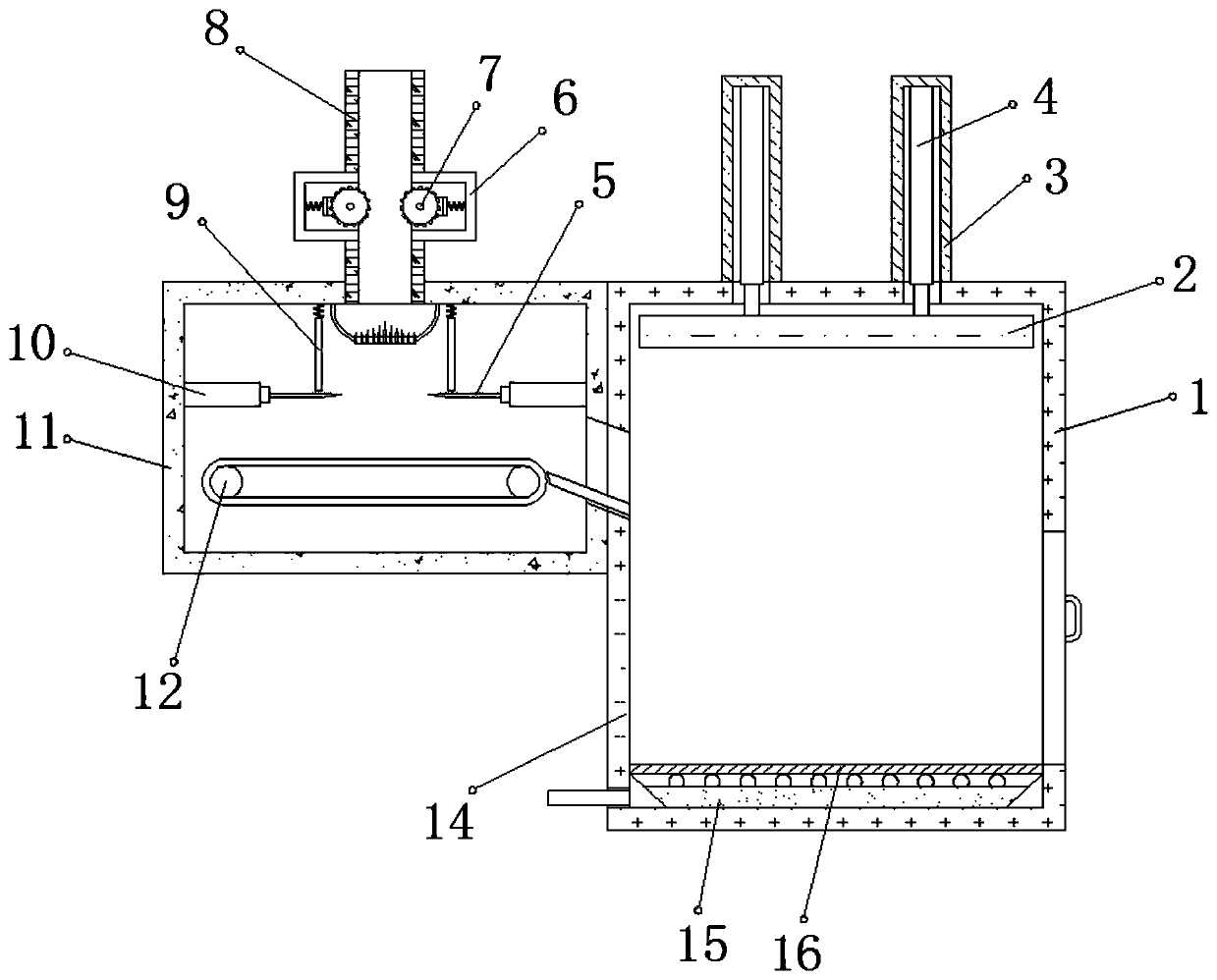

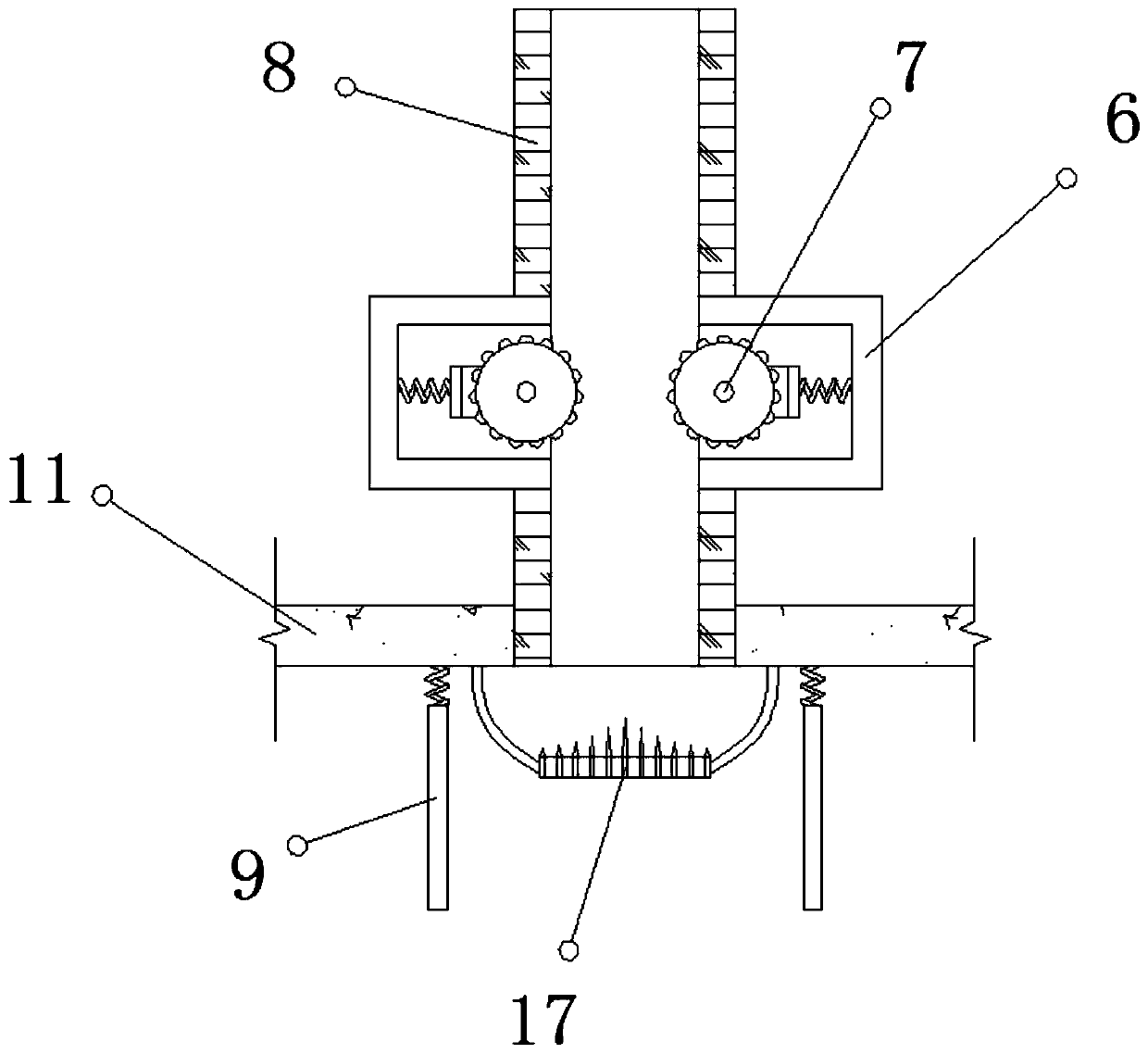

[0026] refer to Figure 1-3 , a sucrose purification device for sugarcane processing, comprising a squeeze box 1, the top outer wall of the squeeze box 1 is connected with a fixed shell 3 by fastening bolts, and the top inner wall of the fixed shell 3 is connected with a hydraulic cylinder 4 by fastening bolts, the hydraulic cylinder 4 One end extending to the inside of the press box 1 is connected with the lower platen 2 through fastening bolts, and the top of the outer wall of one side of the press box 1 is connected with the pretreatment box 11 through fastening bolts, and the top outer wall of the pretreatment box 11 is plugged with an upper Barrel 8, the top inner wall of the pretreatment box 11 is connected with the slitting screen 17 by fastening bolts, and the tops of the inner walls on both sides of the pretreatment box 11 are connected with the first electric telescopic rod 10 by fastening bolts, and the two second One end of an electric telescopic rod 10 is connecte...

Embodiment 2

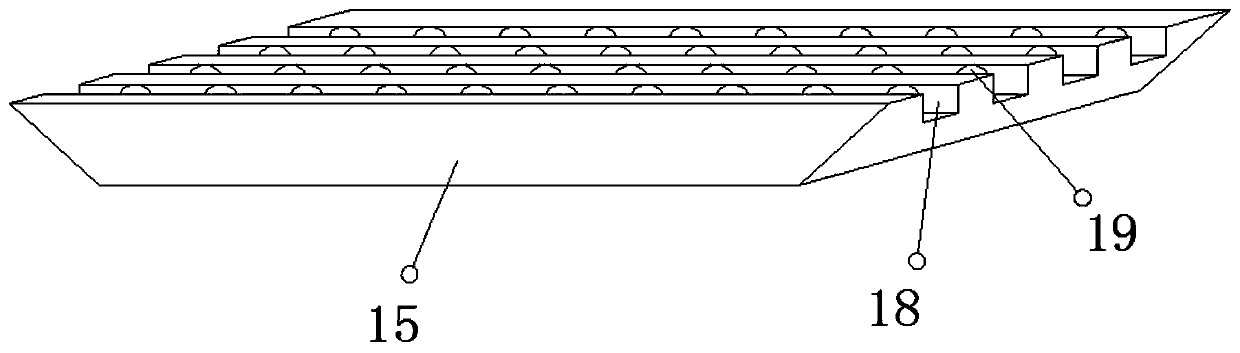

[0033] refer to Figure 4 , a sucrose purification device for sugarcane processing. Compared with Embodiment 1, the outer wall of the bottom of the pretreatment box 11 is connected with a fixed plate by fastening bolts, and the bottom of one side of the fixed plate is connected with a second fixed plate by fastening bolts. The electric telescopic rod 13 and the second electric telescopic rod 13 extend to one end inside the press box 1 and are connected with a push plate 14 by fastening bolts.

[0034] Working principle: After the pressing is completed, open the dodge door, and push the push plate 14 through the second electric telescopic rod 13 to remove the bagasse on the base 15, which is convenient and efficient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com