Industrial boiler flue gas desulfurization and denitrification equipment

A desulfurization and denitrification, industrial boiler technology, applied in the direction of gas treatment, dispersed particle filtration, membrane technology, etc., can solve the problems of reducing exhaust cleanliness, pollution, and inability to carry out secondary utilization, so as to improve the utilization rate of flue gas and improve The effect of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

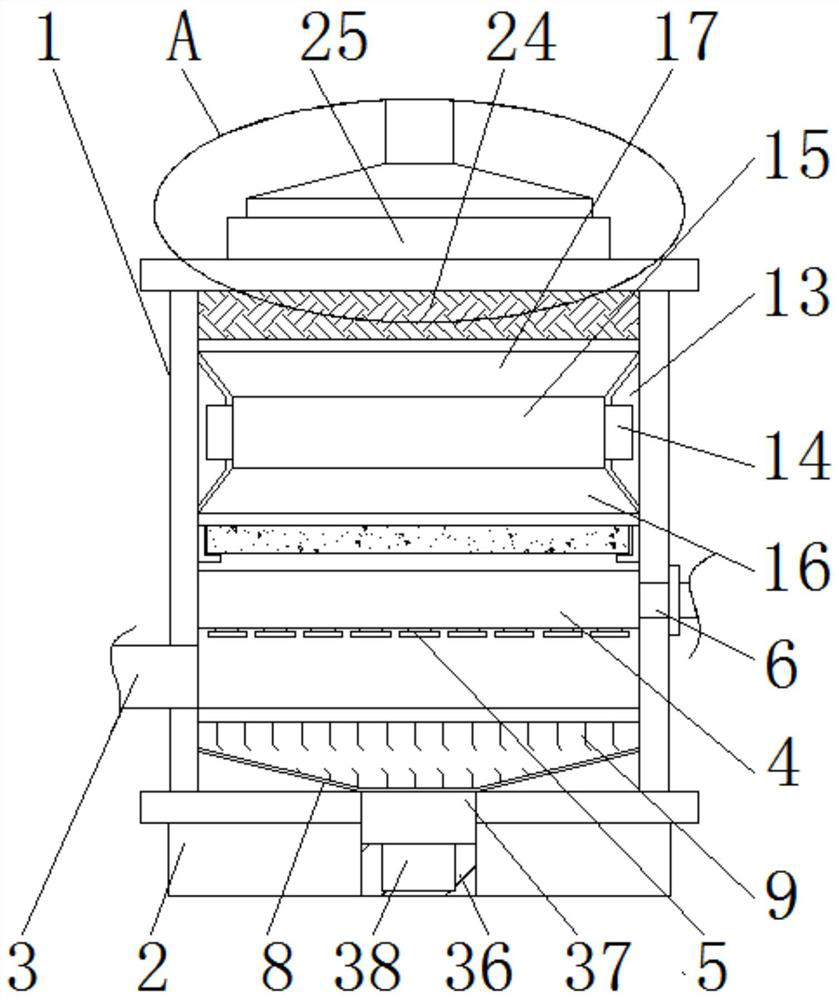

[0037] see Figure 1-7, the present invention provides an industrial boiler flue gas desulfurization and denitrification equipment, including a furnace body 1, an air inlet pipe 3 is welded vertically at the middle position of the side wall bottom of the furnace body 1, and the inner wall positions on both sides of the furnace body 1 are vertically fixed and installed There are S-shaped conduits 4, and several groups of nozzles 5 are uniformly and fixedly installed on the bottom of the S-shaped conduits 4. The side wall of the furnace body 1 away from the intake pipe 3 is welded with a pipe sleeve 6, and the furnace body 1 is provided with a water pipe through the pipe sleeve 6. 7. One end of the water pipe 7 is vertically fixed and connected to the middle position on the front side of the side wall of the S-shaped conduit 4. Guide blocks 8 are fixedly installed on both sides of the bottom of the inner wall of the furnace body 1, and two sets of guide blocks 8 are combined into...

Embodiment 2

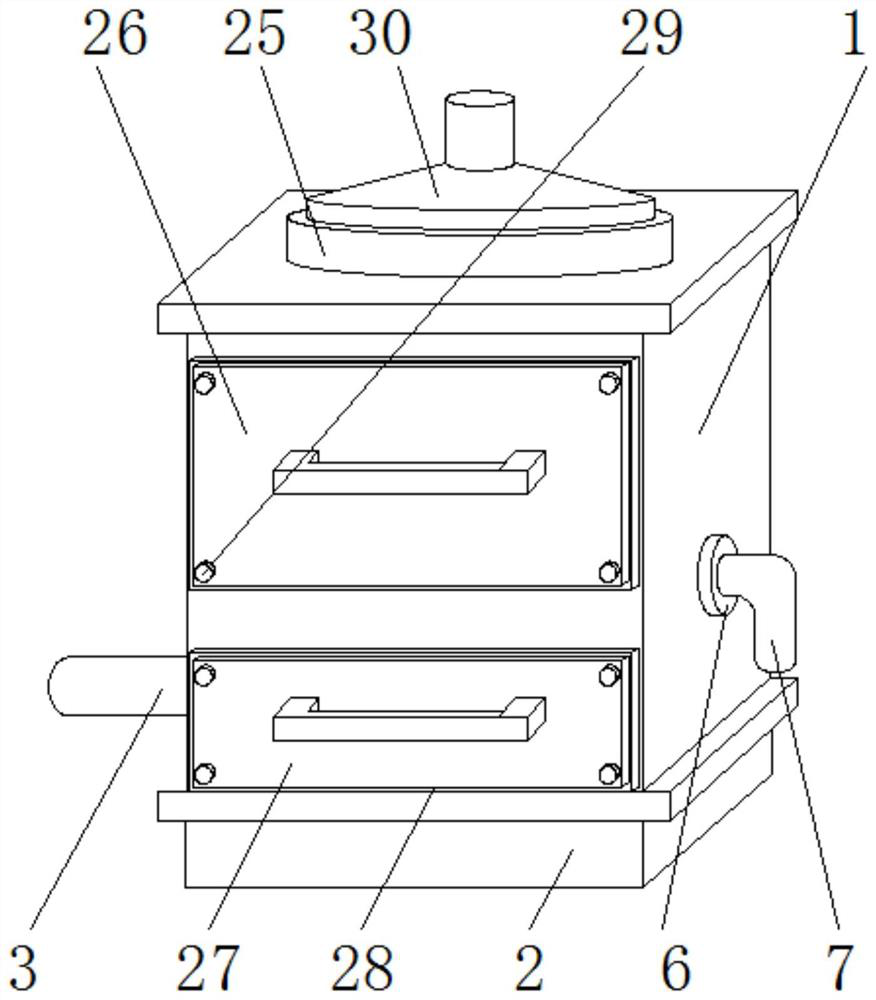

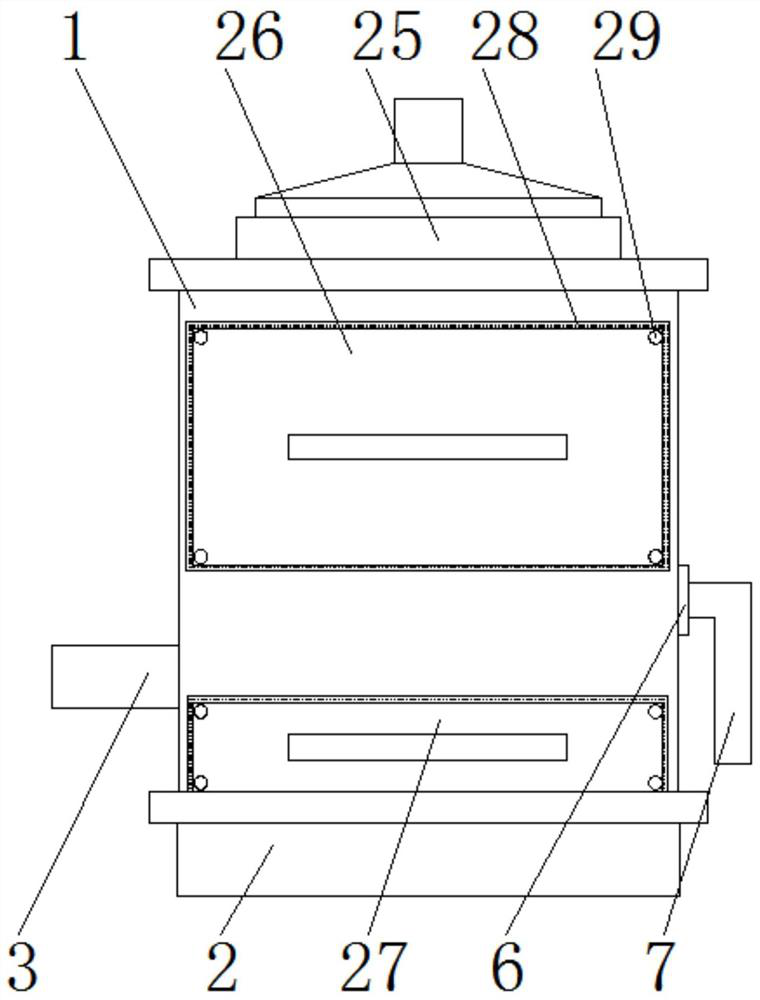

[0039] see Figure 2-8 , the present invention provides an industrial boiler flue gas desulfurization and denitrification equipment, including a furnace body 1, an air inlet pipe 3 is welded vertically at the middle position of the side wall bottom of the furnace body 1, and the inner wall positions on both sides of the furnace body 1 are vertically fixed and installed There are S-shaped conduits 4, and several groups of nozzles 5 are uniformly and fixedly installed on the bottom of the S-shaped conduits 4. The side wall of the furnace body 1 away from the intake pipe 3 is welded with a pipe sleeve 6, and the furnace body 1 is provided with a water pipe through the pipe sleeve 6. 7. One end of the water pipe 7 is vertically fixed and connected to the middle position on the front side of the side wall of the S-shaped conduit 4. Guide blocks 8 are fixedly installed on both sides of the bottom of the inner wall of the furnace body 1, and two sets of guide blocks 8 are combined int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com