Brown sugar processing technology

A processing technology, brown sugar technology, applied in sugar products, sucrose production, sugar production and other directions, can solve problems such as long time, and achieve the effects of shortening flow distance, improving concentration efficiency and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: a kind of brown sugar processing technology comprises the following steps:

[0029] Step 1. Cutting into segments and freezing: cutting the sugarcane into segments, and storing the segmented sugarcane in a -16°C environment for 8 hours;

[0030] Step 2. Squeeze and filter: Take out the frozen segmented sugarcane and crush the segmented sugarcane in an environment of ≤15°C, then squeeze it with a heavy object to collect the squeezed sugarcane juice; the squeezed sugarcane The slag is put into the container 2, and after warming up at normal temperature, it is crushed to squeeze the juice, and the squeezed sugarcane juice is filtered with gauze and mixed with the sugarcane juice squeezed for the first time;

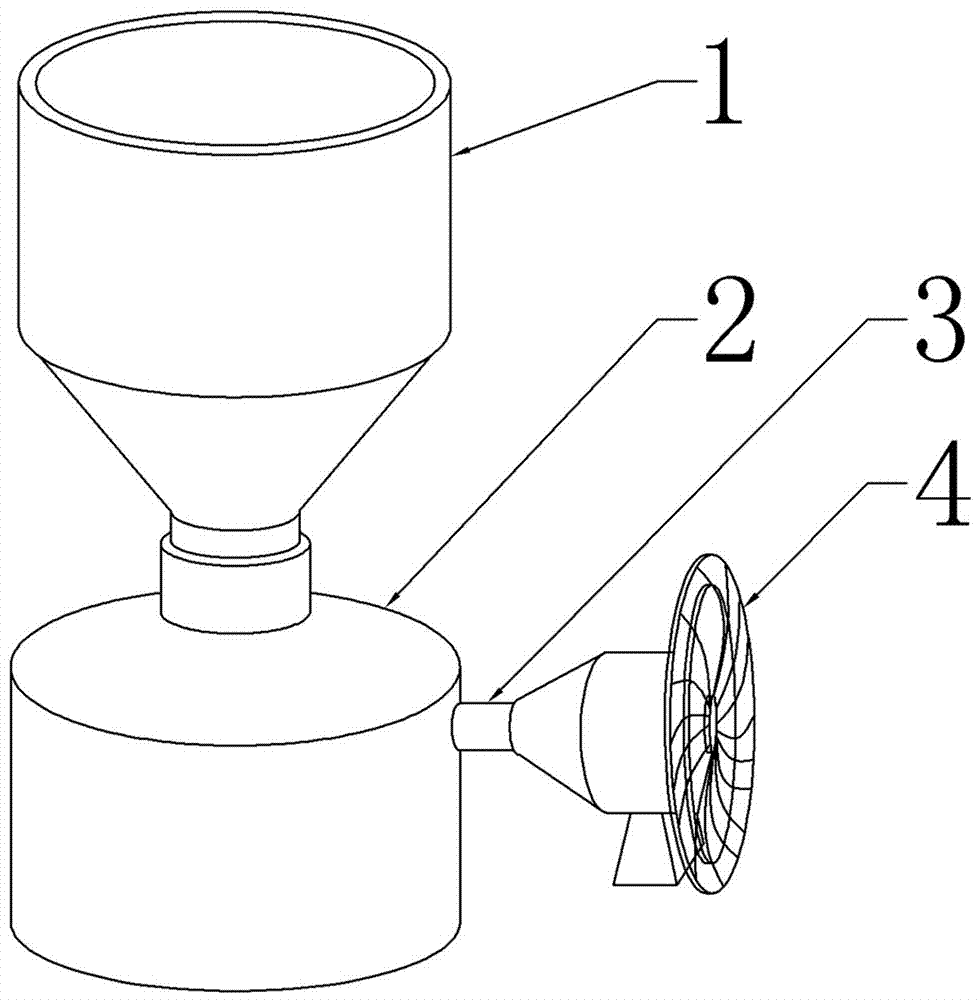

[0031] Wet the filter paper in the funnel 1, then pour the sugarcane juice into the funnel 1, start the fan 4 to carry out suction filtration, so that the sugarcane juice in the funnel 1 enters the container 2 below the funnel 1;

[0032] Step 3. Vacuum...

Embodiment 2

[0035] Embodiment 2: a kind of brown sugar processing technology comprises the following steps:

[0036] Step 1. Cutting into segments and freezing: Cut the sugarcane into segments, and store the segmented sugarcane in a -22°C environment for 6 hours;

[0037] Step 2. Squeeze and filter: Take out the frozen segmented sugarcane and crush the segmented sugarcane in an environment of ≤15°C, then squeeze it with a heavy object to collect the squeezed sugarcane juice; the squeezed sugarcane The slag is put into the container 2, and after warming up at normal temperature, it is crushed to squeeze the juice, and the squeezed sugarcane juice is filtered with gauze and mixed with the sugarcane juice squeezed for the first time;

[0038]Wet the filter paper in the funnel 1, then pour the sugarcane juice into the funnel 1, start the fan 4 to carry out suction filtration, so that the sugarcane juice in the funnel 1 enters the container 2 below the funnel 1;

[0039] Step 3, vacuum concen...

Embodiment 3

[0042] Embodiment 3: a kind of brown sugar processing technology comprises the following steps:

[0043] Step 1. Cutting into segments and freezing: cutting the sugarcane into segments, and storing the segmented sugarcane in a -20°C environment for 7 hours;

[0044] Step 2. Squeeze and filter: Take out the frozen segmented sugarcane and crush the segmented sugarcane in an environment of ≤15°C, then squeeze it with a heavy object to collect the squeezed sugarcane juice; the squeezed sugarcane The slag is put into the container 2, and after warming up at normal temperature, it is crushed to squeeze the juice, and the squeezed sugarcane juice is filtered with gauze and mixed with the sugarcane juice squeezed for the first time;

[0045] Wet the filter paper in the funnel 1, then pour the sugarcane juice into the funnel 1, start the fan 4 to carry out suction filtration, so that the sugarcane juice in the funnel 1 enters the container 2 below the funnel 1;

[0046] Step 3. Vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com