Sugarcane cutting machine for sugar production

A hood and telescopic rod technology, applied in the direction of sugarcane cutting, can solve the problems of large volume, complex structure of the cane cutting machine, inconvenient movement, etc., and achieve the effect of solving the complex structure, reducing the occupied space and facilitating the collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

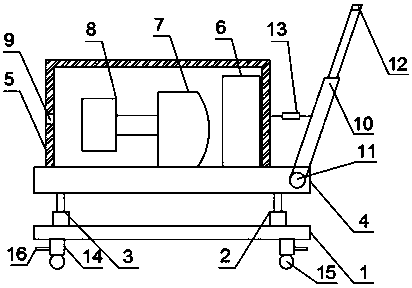

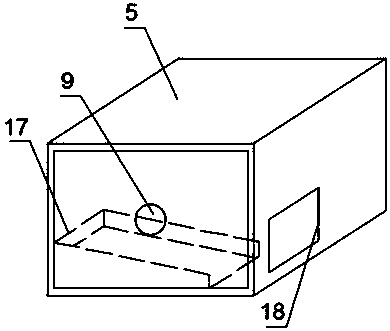

[0017] Such as Figure 1-2 As shown, the present invention provides a cane cutter for sugar production, comprising a base 1, a first telescopic rod 2, a second telescopic rod 3, a workbench 4, a machine cover 5, a storage battery 6, an infinitely variable speed motor 7, a rotary cutter 8. Inlet 9, pull rod 10, rotating shaft 11, handle 12, return spring 13, support leg 14, universal wheel 15, locking buckle 16, chute 17 and collection port 18, and the surface of base 1 is symmetrically provided with the first A telescopic rod 2 and a second telescopic rod 3, the top surfaces of the first telescopic rod 2 and the second telescopic rod 3 are provided with a workbench 4, the surface of the workbench 4 is provided with a machine cover 5, and the inside of the machine cover 5 is sequentially provided with a battery 6. Steplessly variable speed motor 7 and rotary tool 8, steplessly variable speed motor 7 is connected to rotary tool 8 through the motor shaft, one side of machine cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com