Continuous cooking machine

A cooking machine and steam technology, applied in sugar solution boiling/evaporation, sucrose production, sugar production, etc., can solve problems such as difficulty in cleaning, lengthening of candy flow distance, accumulation of raw materials, etc., to achieve consistency, short mixing time, and guaranteed The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

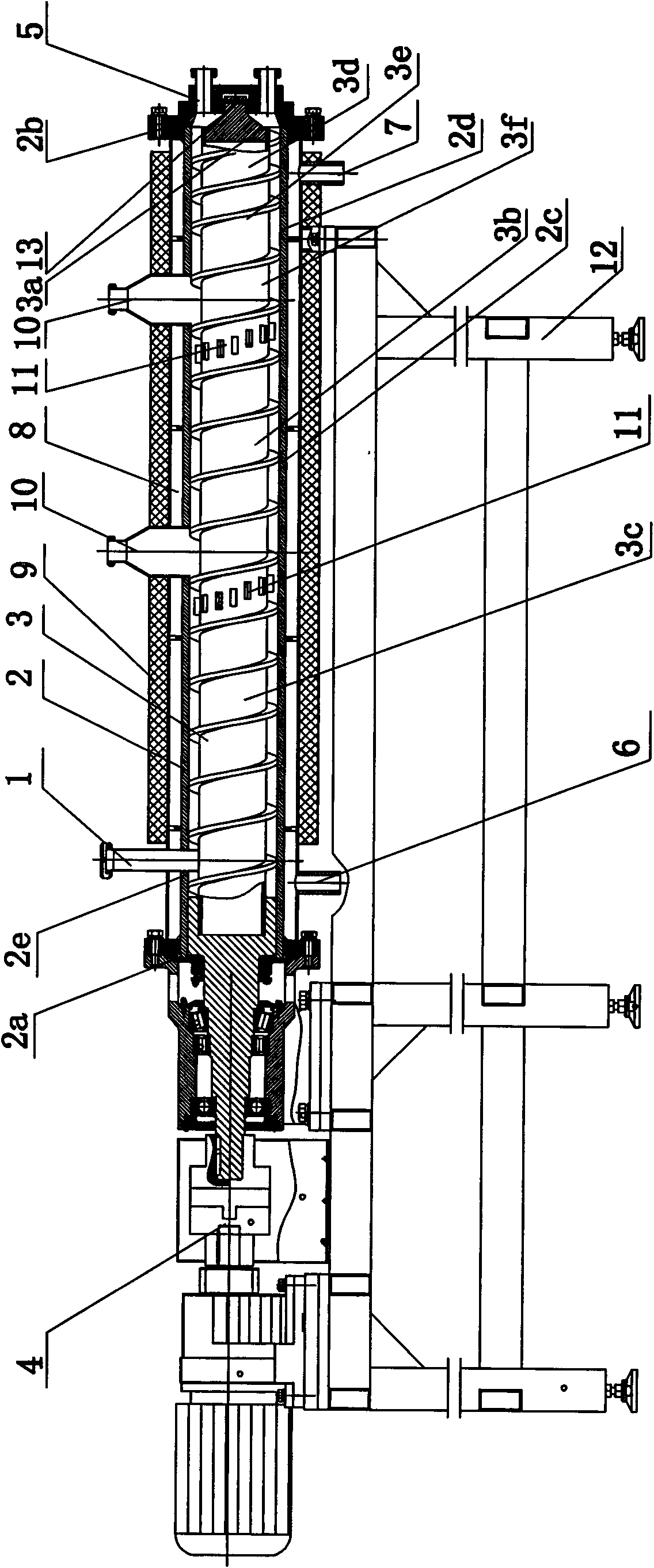

[0014] As shown in the figure, the present invention includes a conveying circular pipe 2 fixed on the frame 12 and having more than one feed inlet 1 on the side of the front section 2e, and a screw thread outer diameter and conveying circle arranged in the conveying circular pipe 2 by rotation. The screw rod 3 with matching inner diameter of the pipe 2, the power mechanism 4 fixed on the front end 2a of the conveying round pipe 2 to drive the screw 3 to rotate, the extrusion nozzle 5 fixed on the rear end 2b of the conveying round pipe 2, and the outer wall of the conveying round pipe 2 A heating jacket 8 with a medium inlet 6 and a medium outlet 7 is provided, an insulation layer 9 is provided on the outer wall of the heating jacket 8, a bearing 13 is provided in the middle of the inner side of the extrusion nozzle 5, and the tail end 3a of the screw rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com