Method for treating sugarcane mixed clear juice

A processing method and technology for clear juice, which are applied in the field of processing sugarcane mixed clear juice by membrane method, can solve the problems of high steam consumption and inability to reach the refining index, etc., and achieve the effects of high degree of automation, long service life and low operating cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take the mixed clear juice, the indicators are as follows:

[0026] Calibration Brix BX 0

Luminosity conversion (sucrose%)

Simple purity (%)

Turbidity (NTU)

Color value IU

15.8

13.79

87.30

7.61

959.91

[0027] The mixed clear juice is a mixed liquid of clear juice and filtered juice obtained by processing the squeezed sugarcane juice through a clarification process.

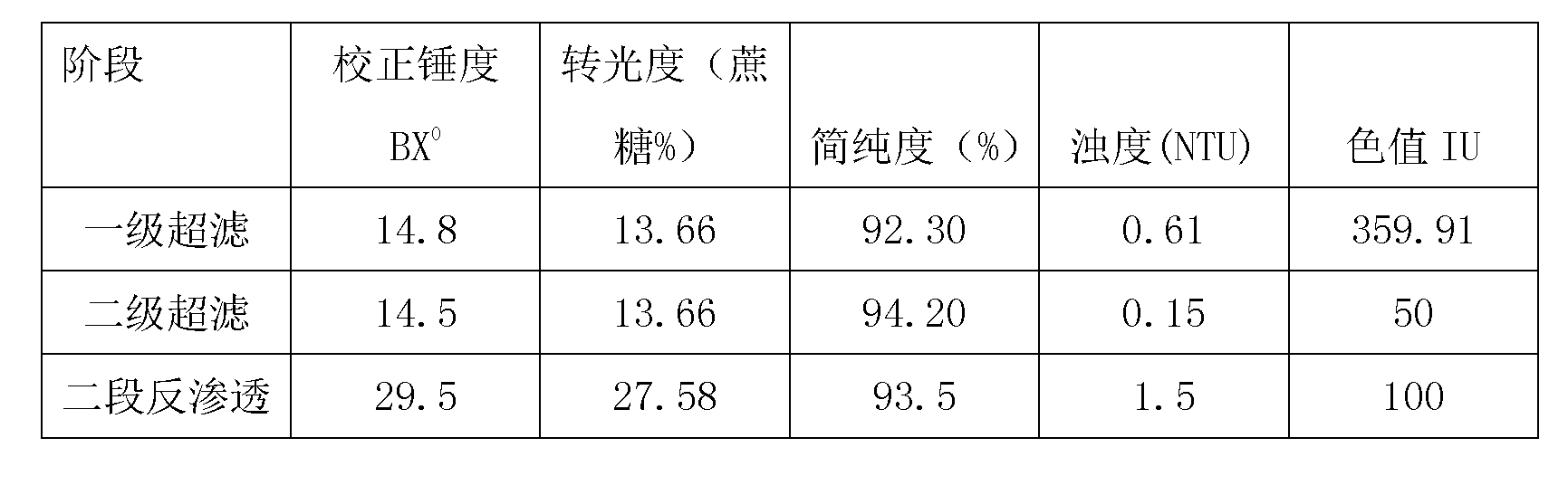

[0028] Then the above-mentioned mixed clear juice is sent to the first-stage ultrafiltration membrane, the molecular weight cut-off of the ultrafiltration membrane is 50,000 Daltons, the operating pressure is controlled at 0.1MPa, the temperature is controlled at 25°C, the filtration time is 24 minutes, and the pH of the feed liquid is controlled at 7 , the index of the clear liquid obtained by filtration is shown in the table below, the first-stage ultrafiltration is filtered, and the recovery rate is controlled to 60%; the concentrated liquid filte...

Embodiment 2

[0034] The mixed clear juice identical with embodiment 1, index is as follows:

[0035] Calibration Brix BX 0

Luminosity conversion (sucrose%)

Simple purity (%)

Turbidity (NTU)

Color value IU

15.8

13.79

87.30

7.61

959.91

[0036] The mixed clear juice is a mixed liquid of clear juice and filtered juice obtained by processing the squeezed sugarcane juice through a clarification process.

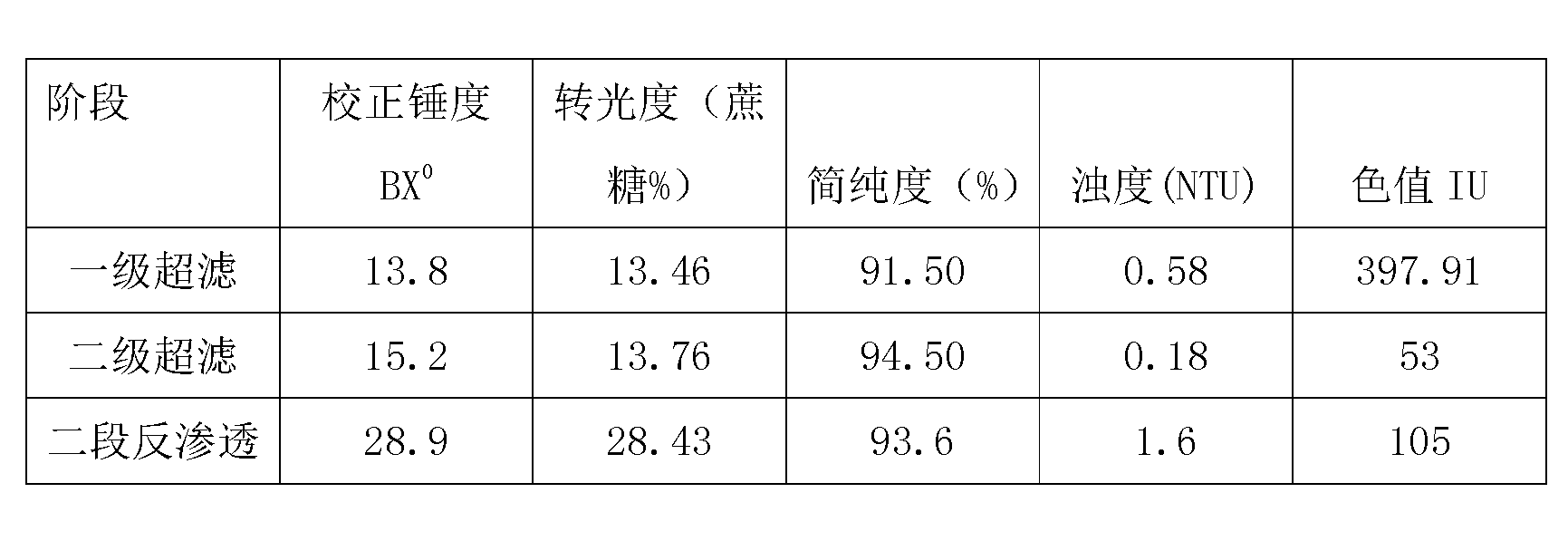

[0037] Then the above-mentioned mixed clear juice is sent to the first-stage ultrafiltration membrane, the molecular weight cut-off of the ultrafiltration membrane is 80,000 Daltons, the operating pressure is controlled at 0.2MPa, the temperature is controlled at 30°C, the filtration time is 15 minutes, and the pH of the feed liquid is controlled at 7 , the first-stage ultrafiltration is used for filtration, and the recovery rate is controlled to 70%; the dope filtered by the first-stage ultrafiltration membrane is evaporated to produce ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com