Processing method of acid gas

A treatment method and acid gas technology, applied in combustion methods, separation methods, chemical instruments and methods, etc., can solve the problems of excess gypsum products, low desulfurization efficiency, ammonia escape, etc., so as to reduce operating costs and difficulties, and realize recycling. , the effect of simplifying the processing flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

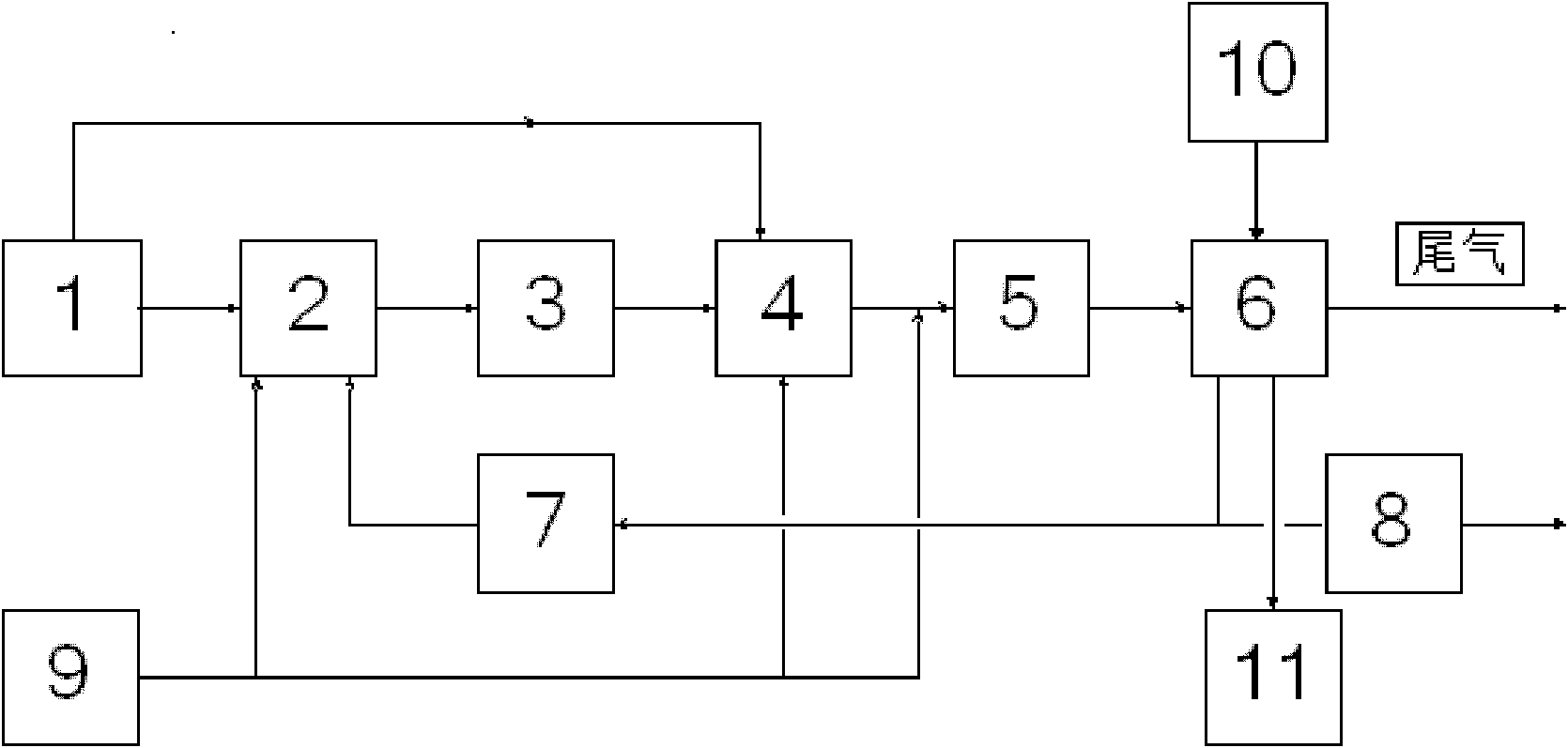

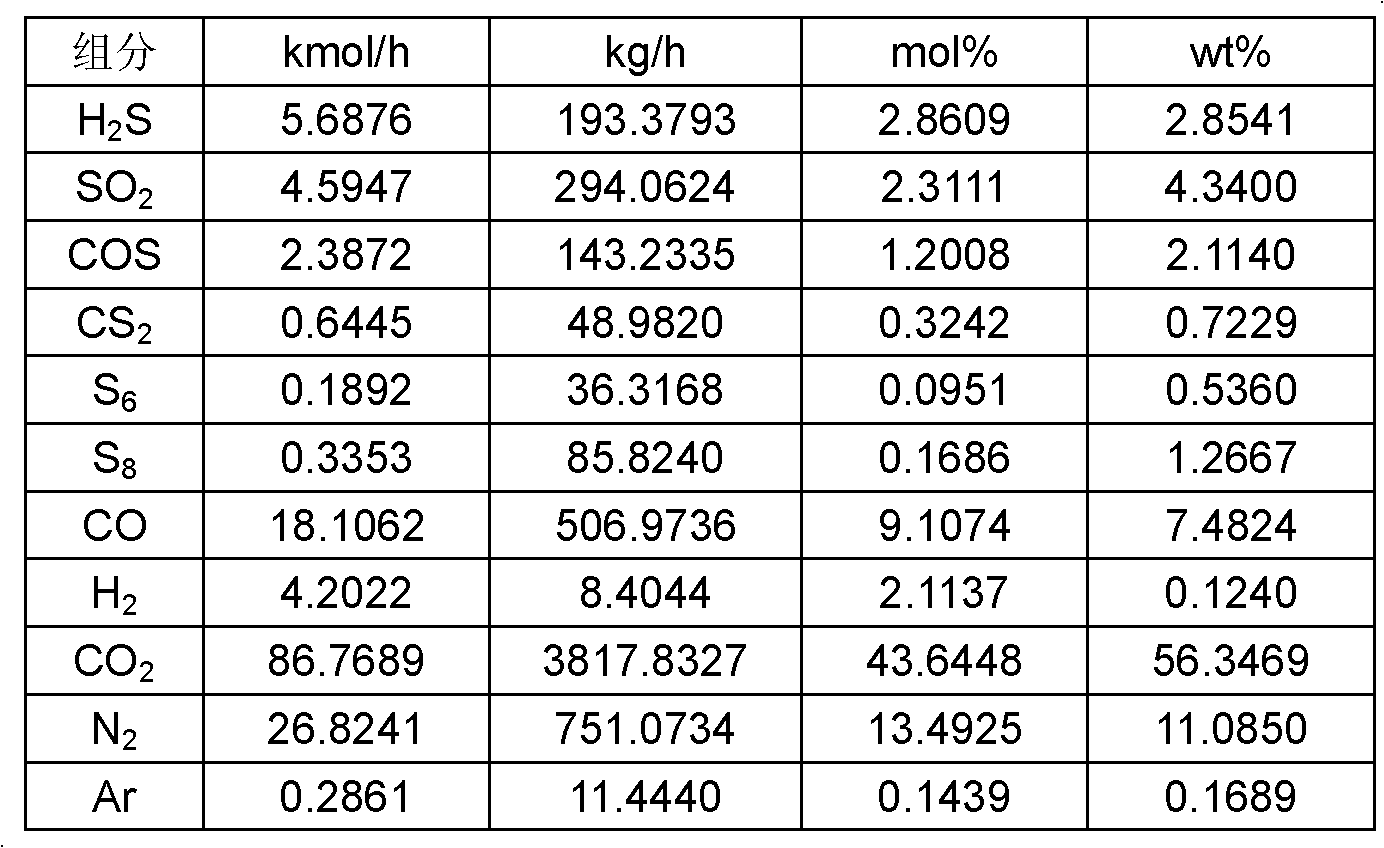

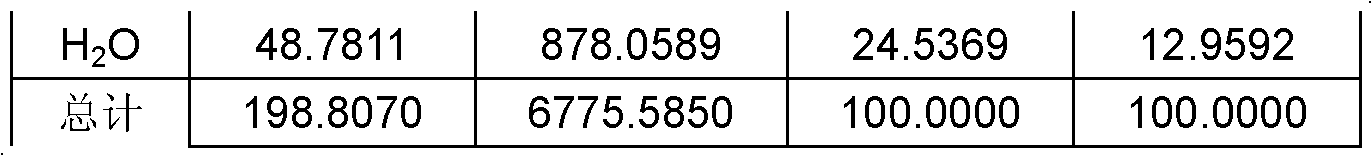

[0042] like figure 1 As shown, the acid gas 1 at about 40°C and the oxygen-containing gas from 9, such as air or pure oxygen, enter the sulfur production combustion furnace 2 for combustion, and after recovering part of the sulfur, the gas enters the secondary Claus converter 3 for further sulfur production. Recycling, Claus tail gas and hot air from 11 are incinerated in the incinerator 4, first preheated to 350°C, and then incinerated, the incineration temperature is 1100-1350°C, and the sulfur compounds are converted into SO 2 , including SO 2 Acid gas mixed with hot air from 11 enters SO 2 Go to SO 3 Converter 5 to achieve SO 2 to SO 3 conversion, in converter 5, the acid gas and the O in the hot air from 11 2 The reaction produces SO 3 , O 2 The dosage is based on the O in the acid gas discharged from the incinerator tail gas 2 and SO 2 The amount and concentration of oxygen, together with conventional techniques, can determine the theoretical amount of oxygen, t...

Embodiment 2

[0069] like figure 1 As shown, the acid gas 1 is incinerated in the incinerator 4 with the hot air from 11 without any sulfur recovery step. It is preheated at 400°C before incineration. The incineration temperature is 1100-1350°C, and the sulfur compounds are converted into SO 2 , including SO 2 Acid gas mixed with hot air from 11 enters SO 2 Convert SO 3 Converter 5 to achieve SO 2 to SO 3 conversion, in the converter 5, the acid gas and the O in the hot air from 11 2 The reaction produces SO 3 , O 2 The dosage is based on the O in the acid gas discharged from the incinerator tail gas 2 and SO 2 The amount and concentration of oxygen, together with conventional techniques, can determine the theoretical amount of oxygen, the actual excess of oxygen is about 15% by volume, SO 2 Go to SO 3 The catalyst adopts platinum catalyst metal platinum, and the space velocity is 4500h -1 , the reaction temperature is 400°C.

[0070] The SO containing 3 The gas enters the acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com