Fermentation method for improving yield of isoleucine

A technology of isoleucine and a fermentation method, which is applied in the field of fermentation to improve the yield of isoleucine, can solve the problems such as the cost of branched-chain amino acids cannot be reduced, the quality cannot reach the pharmaceutical grade, the price cannot rise, and the like. Conducive to respiratory metabolism, beneficial to purity, and to avoid corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

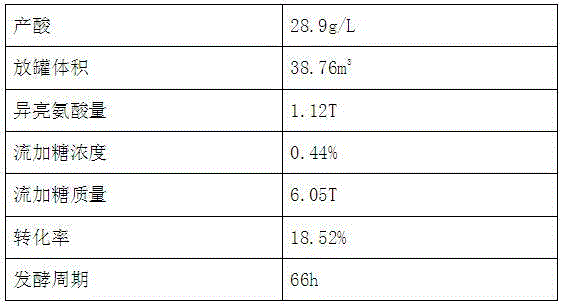

Embodiment 1

[0047] A fermentation method for increasing the yield of isoleucine, the steps are as follows:

[0048] Step 1. Cultivate the bacteria

[0049] Streak inoculate the bacteria on the activated slant, culture at a constant temperature of 31°C for 36-40 hours, expand the culture in the strain room to produce first-level seeds, and then transfer the obtained first-level seeds to the second-level seed tank to continue the expansion and cultivation, and then expand the cultivation to the second-level Sterile air is passed into the seed culture medium, and the ventilation rate is 0.5V / V / M, and the secondary seeds are eliminated, cooled, and cultivated in the secondary seed tank to obtain the secondary seed culture solution, which is set aside; Grade seed medium is composed of raw materials with the following mass concentrations: glucose 25g / L, magnesium sulfate 0.5g / L, potassium dihydrogen phosphate 1.3g / L, ammonium sulfate 5g / L, yeast extract powder 2.2g / L, corn steep liquor hydrolys...

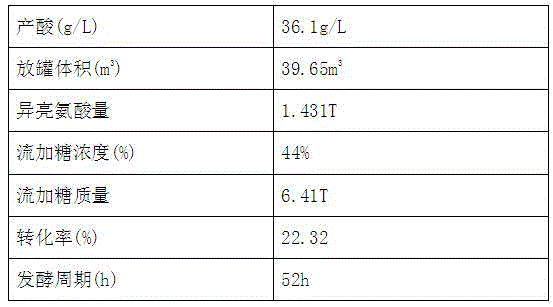

Embodiment 2

[0067] A fermentation method for increasing the yield of isoleucine, the steps are as follows:

[0068] Step 1. Cultivate the bacteria

[0069] Streak inoculate the bacteria on the activated slant, culture at a constant temperature of 31°C for 36-40 hours, expand the culture in the strain room to produce first-level seeds, and then transfer the obtained first-level seeds to the second-level seed tank to continue the expansion and cultivation, and then expand the cultivation to the second-level Sterile air is passed into the seed culture medium, and the ventilation rate is 0.8V / V / M, and the secondary seeds are eliminated, cooled, and cultivated in the secondary seed tank to obtain the secondary seed culture solution, which is set aside; Grade seed medium is composed of raw materials with the following mass concentrations: glucose 35g / L, magnesium sulfate 0.3g / L, potassium dihydrogen phosphate 1.3g / L, ammonium sulfate 5g / L, yeast extract powder 2.2g / L, corn steep liquor hydrolys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com