Impinging stream reactor

A technology of impinging flow reactors and nozzles, applied in chemical/physical/physical chemical nozzle reactors, chemical methods for reacting liquids with liquids, chemical instruments and methods, etc. The chemical reaction promotion effect is not obvious enough to achieve the effect of improving the promotion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

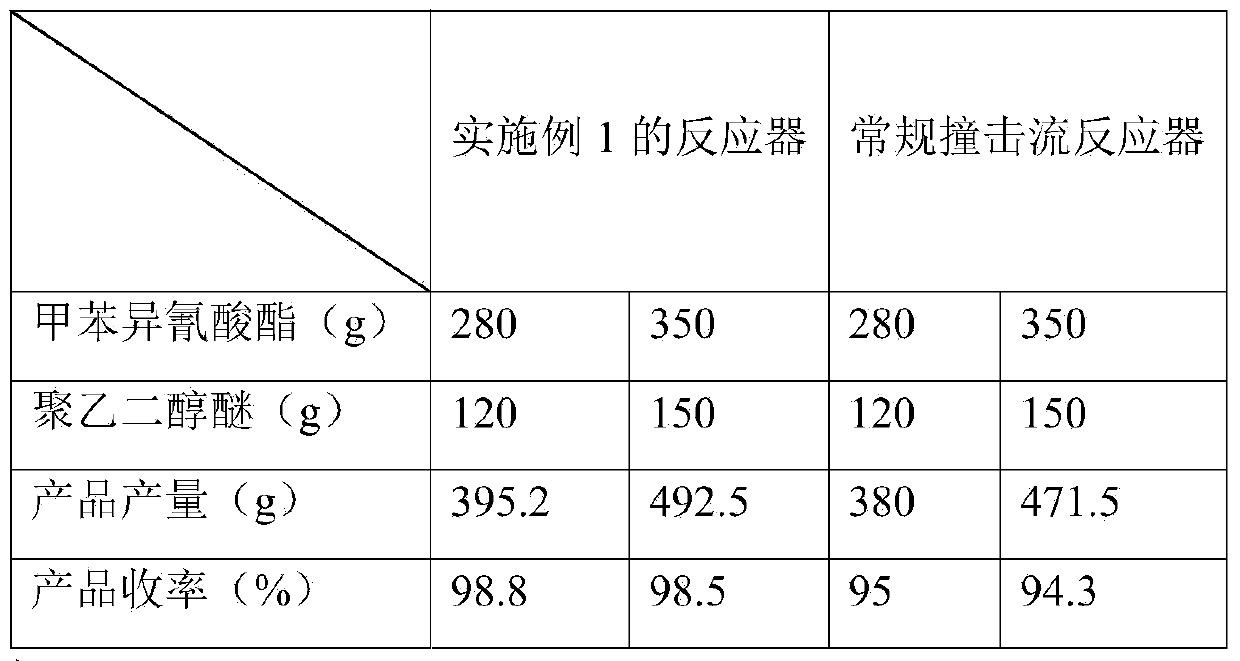

Embodiment 1

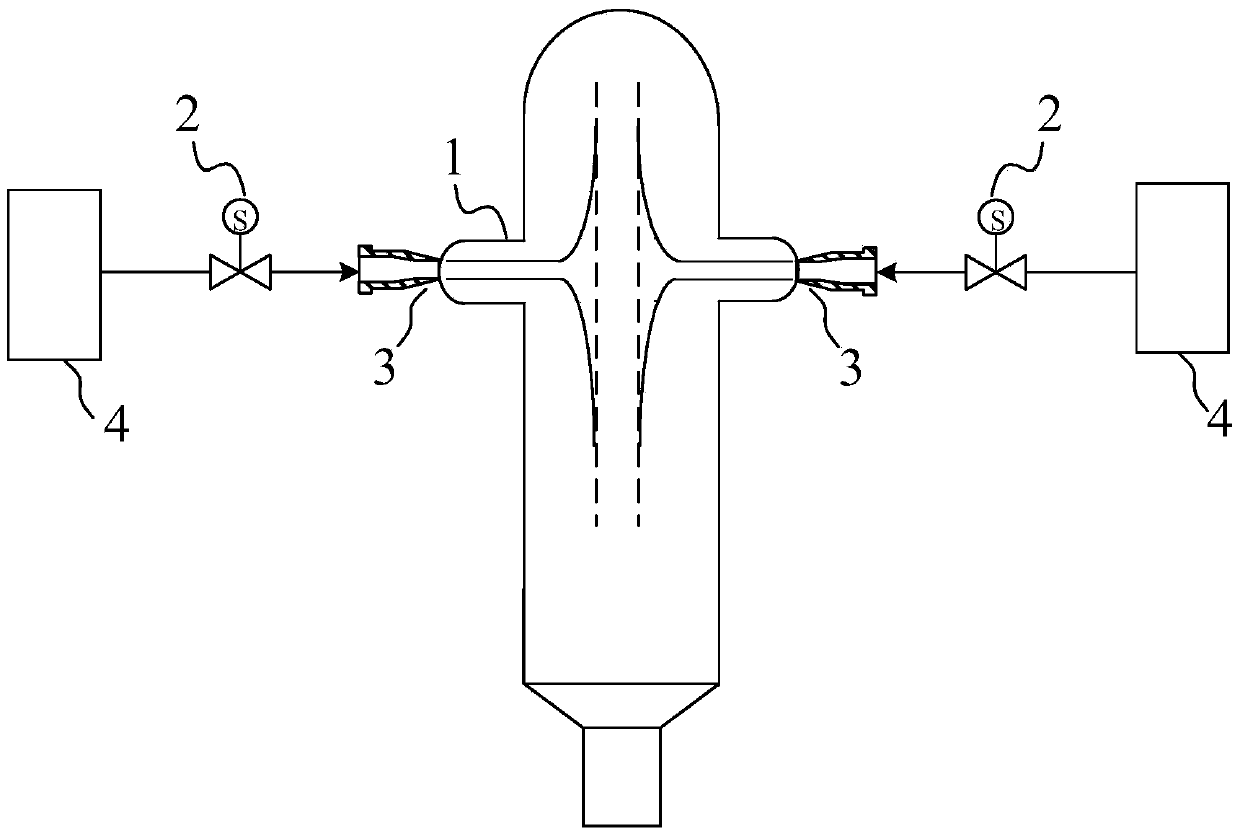

[0024] Such as figure 1 As shown, the impingement flow reactor of this embodiment includes a chamber 1, two storage tanks 4 and two nozzles 3, the two storage tanks 4 are respectively used to feed the two nozzles 3, the two A nozzle 3 is relatively arranged on the side wall of the chamber 1, and its characteristic is that the impingement flow reactor also includes a control unit and two proportional valves 2, and the control unit is used to control the direction of the two proportional valves 2 to The flow rates supplied by the two nozzles 3 are respectively adjusted to fluctuate according to a first preset waveform and a second preset waveform, wherein both the first preset waveform and the second preset waveform are periodic.

[0025] Wherein, the shape and frequency of the first preset waveform and the second preset waveform are the same, and the phase difference is π. The shapes of the first preset waveform and the second preset waveform are both square waves, the frequen...

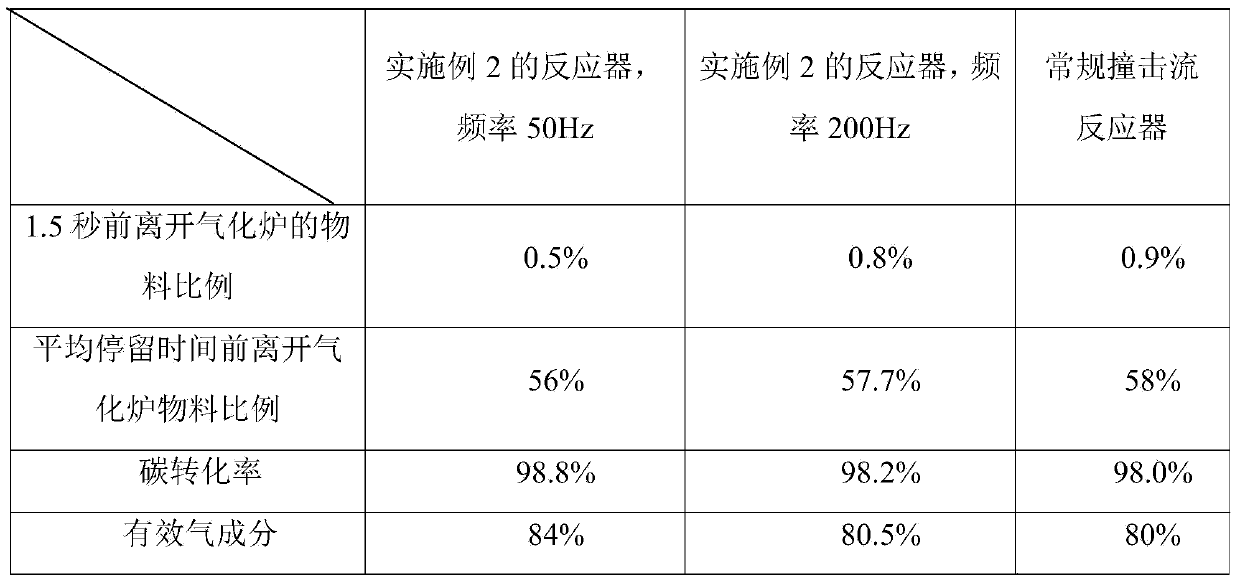

Embodiment 2

[0033] The impingement flow reactor of the present embodiment is compared with embodiment 1, and difference only lies in:

[0034] The amplitudes of the first preset waveform and the second preset waveform are 5% of the average flow rate of the respective corresponding nozzles 3 . At the same time, the chamber 1 is also a gasifier.

[0035] A case where the impinging flow reactor of this embodiment is applied to the gasification of coal-water slurry will be described below. In this case, the materials used for the mixed reaction were 65% Shenfu coal slurry and pure oxygen. The content of each component of Shenfu coal slurry is expressed in mass percentage as follows: the moisture of the original sample is 7.17%, the ash content of the dried sample is 6.58%, the volatile matter is 39.70%, the fixed carbon is 53.72%, the carbon is 69.32%, the hydrogen is 4.72%, and the nitrogen is 0.86% %, sulfur 0.49%.

[0036]In this case, the materials received and ejected by the two nozzl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com