Ethylene propylene rubber and preparation method thereof

A technology of ethylene-propylene rubber and masterbatch, applied in the field of rubber, can solve the problems of poor blending performance of antioxidant and EPDM rubber, poor anti-aging performance, weak action force, etc., so as to improve the synergistic effect. , The effect of improving physical and mechanical properties and improving vulcanization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

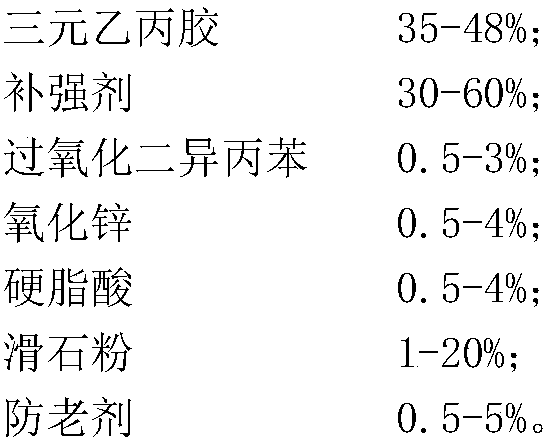

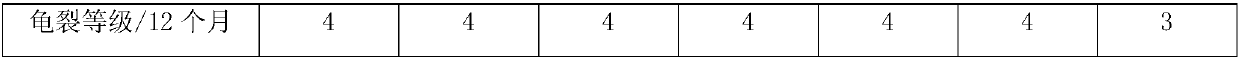

[0027] Embodiment 1: a kind of ethylene propylene rubber, each component and mass percentage in the raw material are as shown in table 2, wherein anti-aging agent is 2,2,4-trimethyl-1,2-dihydroquinoline polymer (anti-aging agent RD). The preparation method of ethylene propylene rubber comprises the following steps, step 1, after weighing the EPDM rubber of formula quantity and adding in the banbury mixer for 4-5 minutes, weigh the nanometer calcium carbonate, carbon black, anti-aging agent of formula quantity , talcum powder for pressurized banburying, until the load of the banbury mixer reaches 180, continue to pressurize the rubber mixing for 2-5 minutes, then discharge the glue to the next piece of the open mill to obtain the masterbatch;

[0028] Step 2, mixing dicumyl peroxide, stearic acid, and nano-zinc oxide, stirring and mixing for 5-10 minutes, to obtain a standby mixture;

[0029] Step 3. After the masterbatch is placed for 12-15 hours, add the masterbatch and the ...

Embodiment 2

[0031] Example 2: An ethylene-propylene rubber, the difference from Example 1 is that the components and mass percentages in the raw materials are shown in Table 2.

[0032] Wherein, the aging test method of the sample is the same as that of Example 1 and the side-by-side test is started at the same time.

Embodiment 3

[0033] Example 3: An ethylene-propylene rubber, the difference from Example 1 is that the components and mass percentages in the raw materials are shown in Table 2.

[0034] Wherein, the aging test method of the sample is the same as that of Example 1 and the side-by-side test is started at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com