Reaction sputtering system based on oscillation-type reaction gas control

A reactive gas and sputtering system technology, applied in sputtering plating, ion implantation plating, metal material coating process, etc., can solve the problems that the film cannot be sputtered, and the composition of the sputtered film is difficult to control.

Active Publication Date: 2013-12-11

WUXI YUANCHUANGHUAXIN MICROELECTROMECHANICAL CO LTD +1

View PDF5 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, it is difficult to control the composition of the sputtered film in the traditional

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

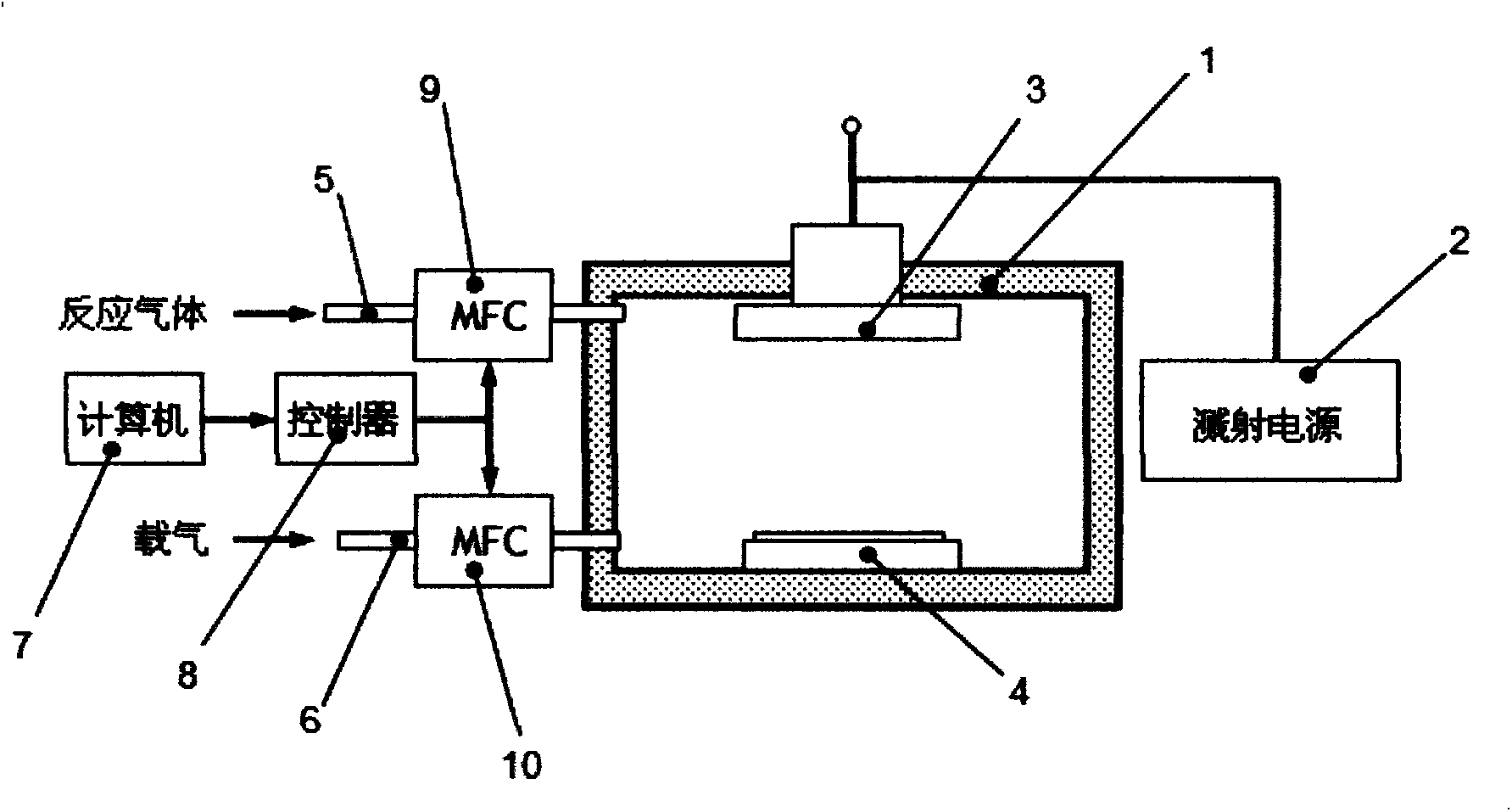

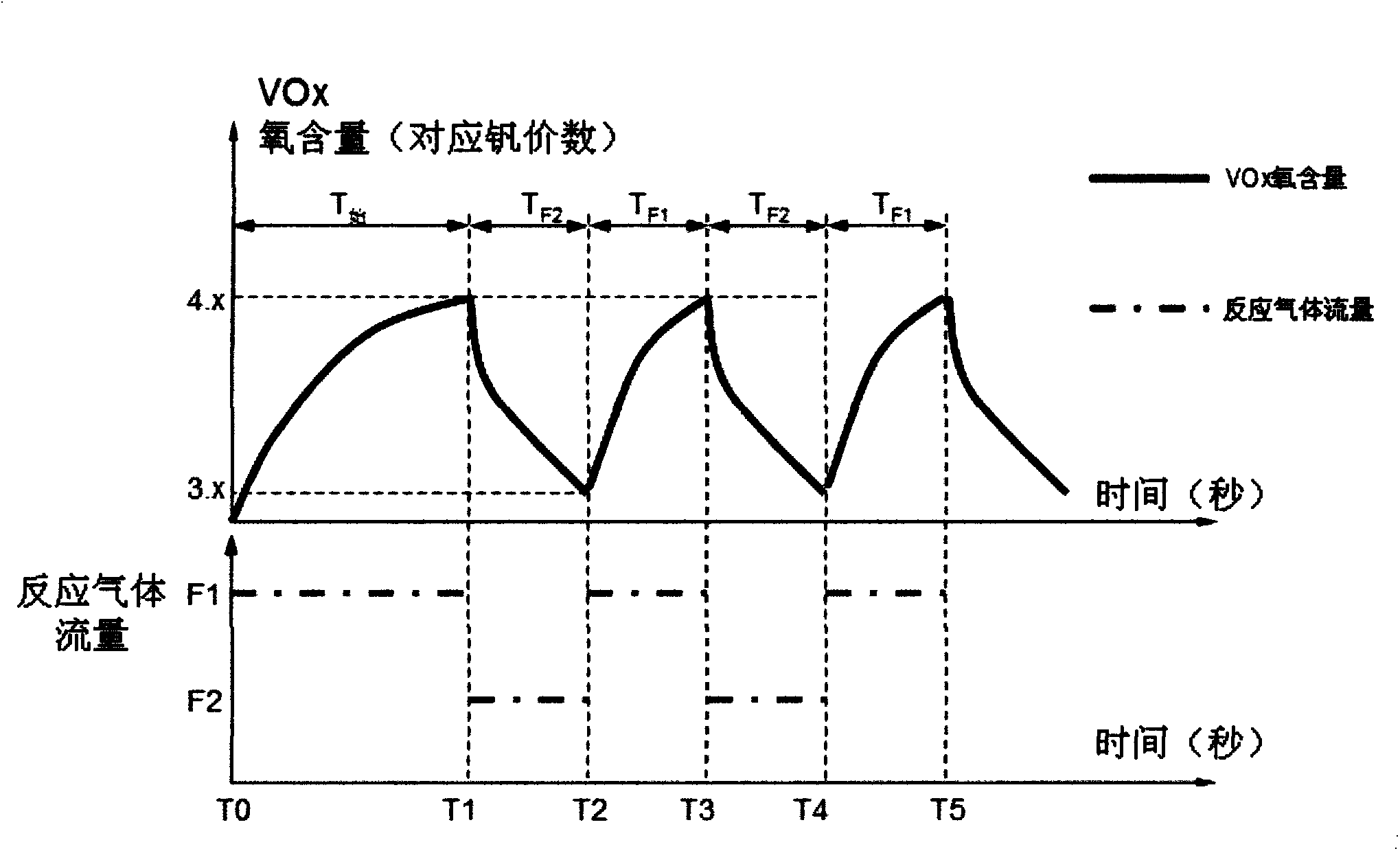

The invention relates to a reaction sputtering system based on oscillation-type reaction gas control. The reaction sputtering system comprises a vacuum chamber, a reaction gas pipeline and a carrier gas pipeline; an anode wafer carrying platform and a cathode target material which face with each other are disposed in the vacuum chamber; the reaction sputtering system also comprises a gas flow control system, and the gas flow control system comprises a computer, a flow controller, a reaction gas mass flowmeter and a carrier gas mass flowmeter; the reaction gas mass flowmeter and the carrier gas mass flowmeter are respectively disposed in the reaction gas pipeline and the carrier gas pipeline; and the computer is used to control the reaction gas mass flowmeter via the flow controller and enable the reaction gas flow entering into the vacuum chamber to be a periodic oscillation flow. By employing the reaction gas flow with periodic oscillation, the reaction sputtering system helps to realize dynamic stabilization of a whole sputter process, and further to realize stable obtaining of needed metallic compound components.

Description

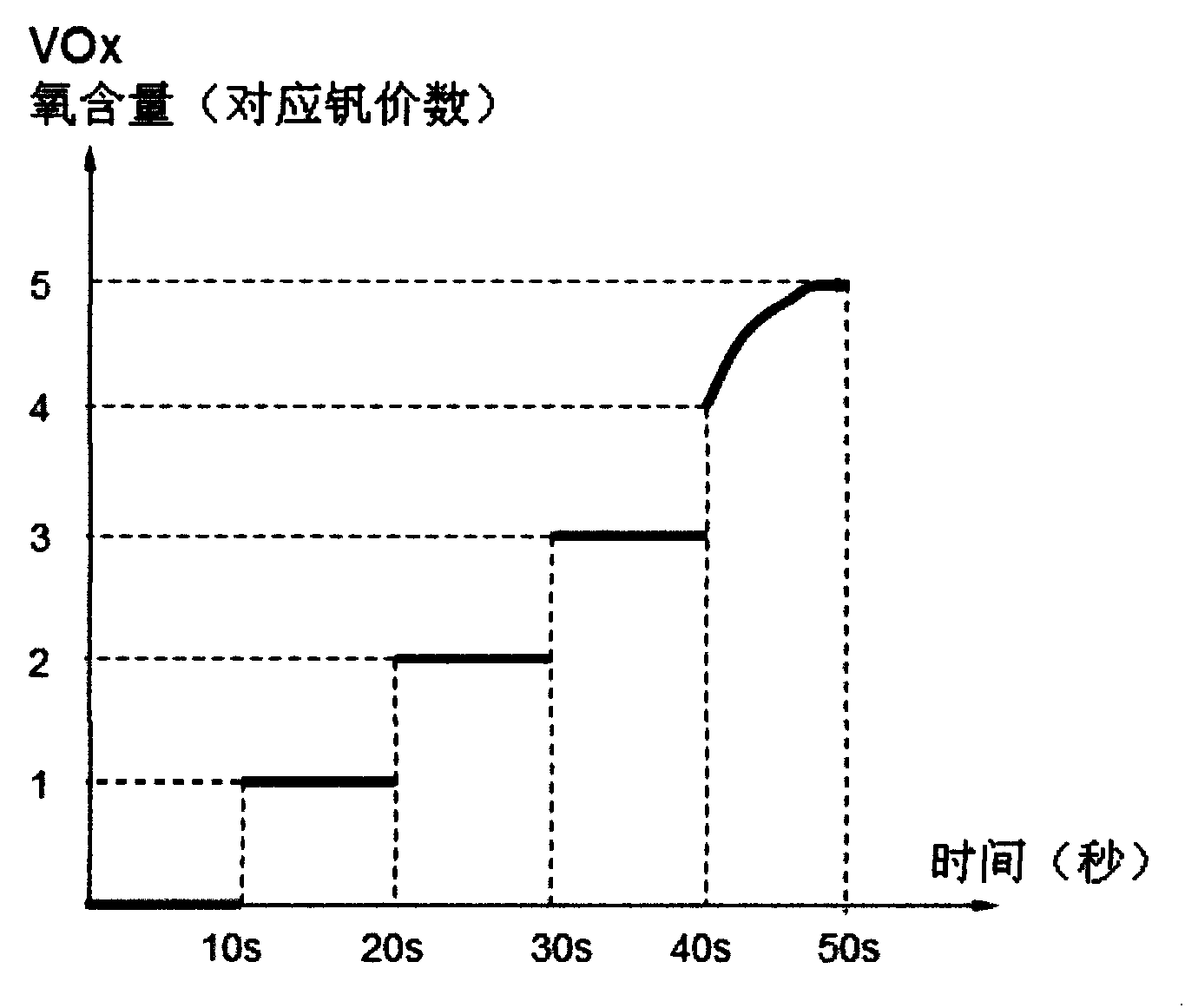

technical field [0001] The invention relates to the technology of preparing metal compound thin film by physical sputtering method, in particular to a reactive sputtering system based on oscillating reactive gas control. Background technique [0002] The reactive sputtering method is a commonly used method for preparing metal compound films. Its working principle is to introduce a certain concentration of reactive gas during the sputtering process, so that the metal ions react with the reactive gas during the sputtering process, thereby obtaining desired compound. [0003] The traditional reactive sputtering system structure includes: vacuum chamber, sputtering power supply, vacuum pump system, wafer transfer system, gas circuit and control system, etc. A wafer carrier is provided in the vacuum chamber for placing the sputtered wafer. A target device is provided on the top of the vacuum chamber, and the target device includes a base for placing the target, a cathode target...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C23C14/34C23C14/54C23C14/08

Inventor 郭俊

Owner WUXI YUANCHUANGHUAXIN MICROELECTROMECHANICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com