Preparation method and system of high-conductivity graphite film

A technology of high thermal conductivity graphite and manufacturing method, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as not being ideal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

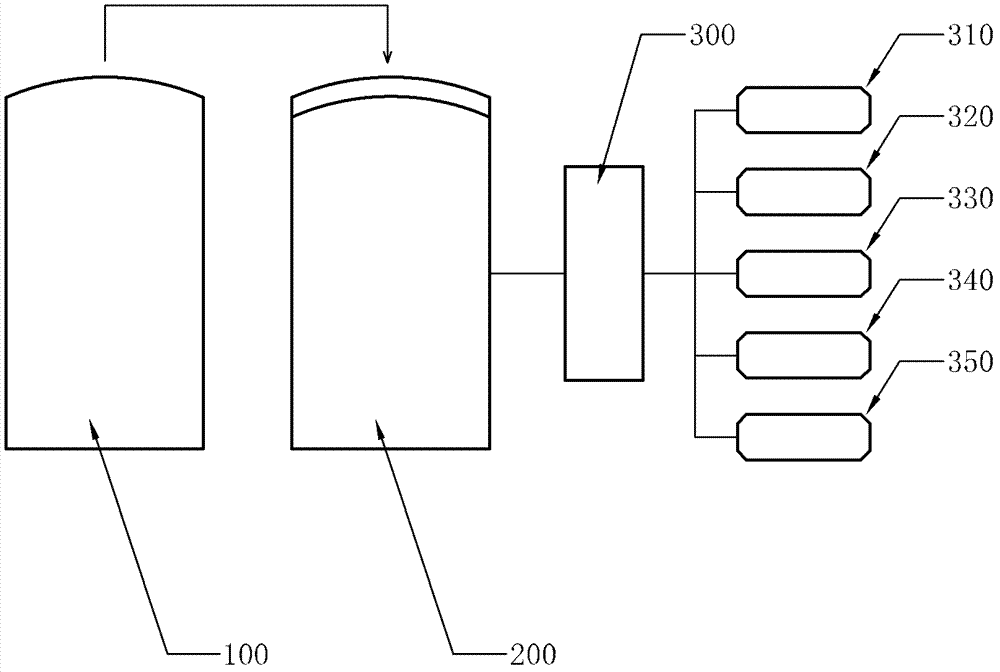

[0039] ginseng figure 1 As shown in the figure, a carbonization furnace 100, a graphitization furnace 200, and a temperature oscillation unit 300 connected to the graphitization furnace are shown. In the temperature oscillation unit 300, a temperature reference point selection module 310, a threshold range setting module 320, a period setting module 330, an oscillation times setting module 340, and a temperature oscillation execution module 350 are provided respectively.

[0040] In this embodiment, the polymer film material used is polyimide (PI) film as an example and not limitation. The thickness of the film is between 5 μm and 500 μm.

[0041] The carbonization furnace 100 is a functional structure for carbonizing polymer film materials. In the present invention, taking polyimide as an example, the implementation process is as follows: the carbonization temperature is suitable to be selected between 600°C and 1800°C, and as an example, it can be selected as 1000°C. Heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com