H-shaped section bar having transverse wave form webs, its making process and forming apparatus for transverse wave form webs

A corrugated web and transverse technology, applied to steel rails, metal rolling, rails, etc., can solve the problems of increased economic burden, increased project cost, and high cost for users, so as to save costs and resources, reduce structural costs, and reduce Effect of Structural Weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

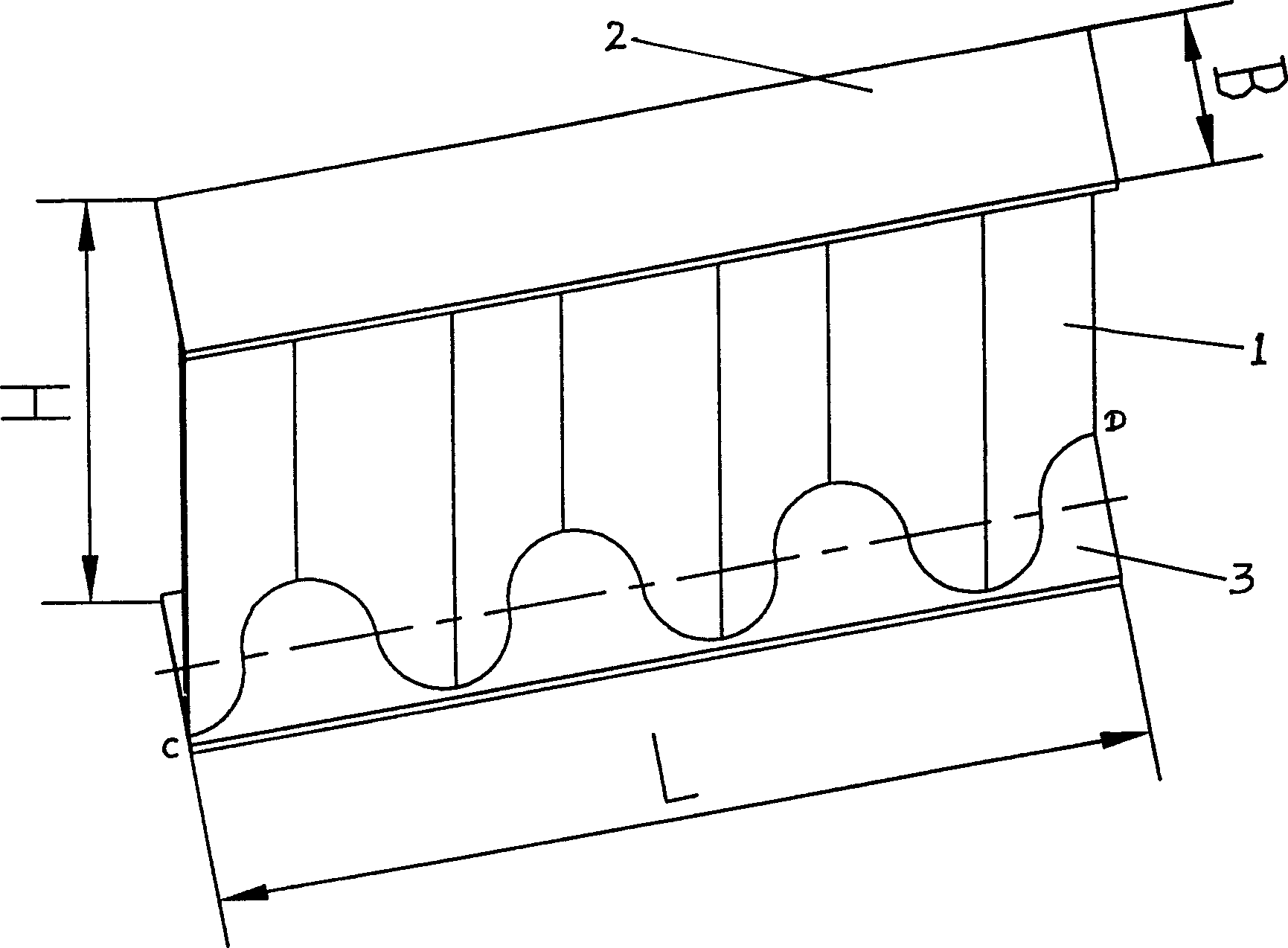

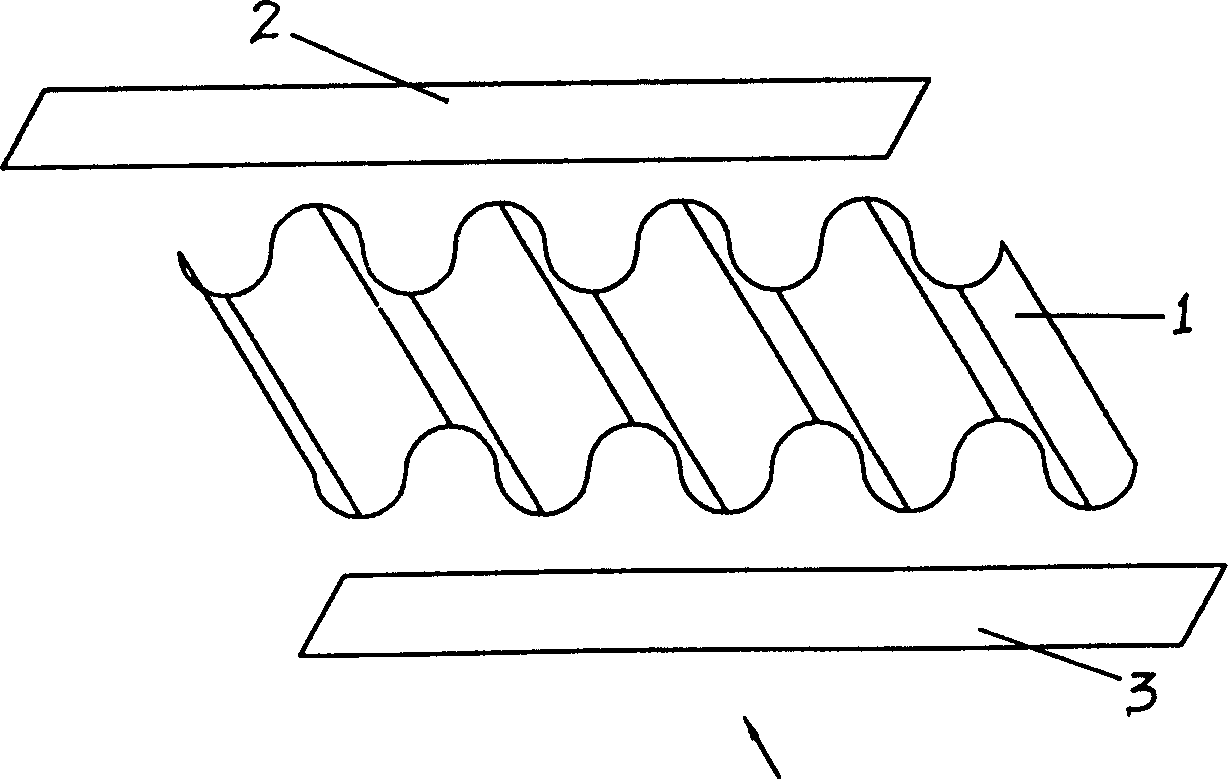

[0032] An H-shaped steel material with a transverse corrugated web, which is welded by a web 1 and two side panels 2 and 3, the web 1 is located in the two side panels 2 and 3, and is characterized in that the web 1 is Corrugated corrugated web. Such as figure 1 As shown, H, B, L in the figure are respectively the web height of the H-shaped steel of the present invention, the width and the length of the wing plate, and its size ranges are respectively: H=300~6000mm, B=100~800mm, L =3000~25000mm.

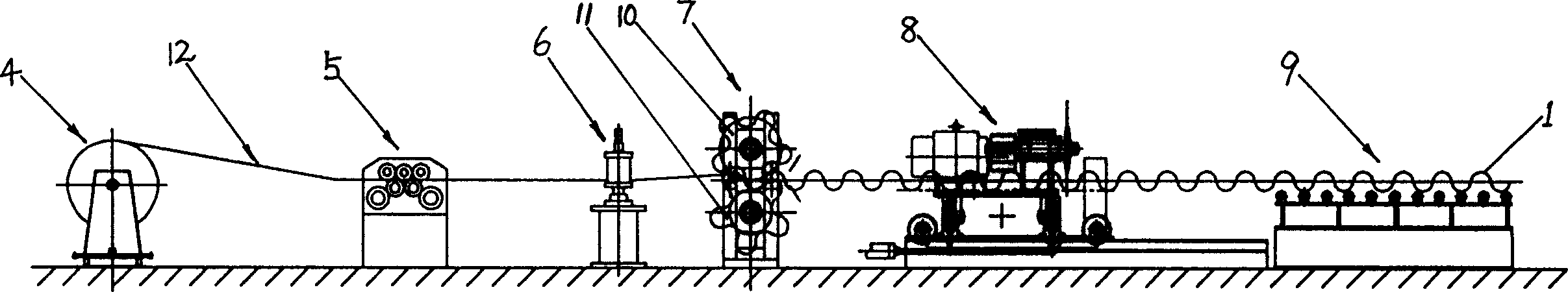

[0033] The transverse corrugated web 1 of the present invention can be formed by welding or one-time continuous cold bending and rolling, but the corrugated web with transverse corrugation formed by one-time continuous cold bending and rolling is the best.

[0034] The corrugated section of the corrugated web 1 can be arc-shaped, involute or trapezoidal; wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com