Dynamic vibration-absorbing multilayer damping-constraining steel rail silencer

A dynamic vibration absorber, restrained damping technology, applied in the direction of rails, tracks, roads, etc., can solve the problems of small damping and poor effect of wood chipboards and blankets, and achieve the effect of convenient construction, convenient installation, low-frequency vibration and noise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

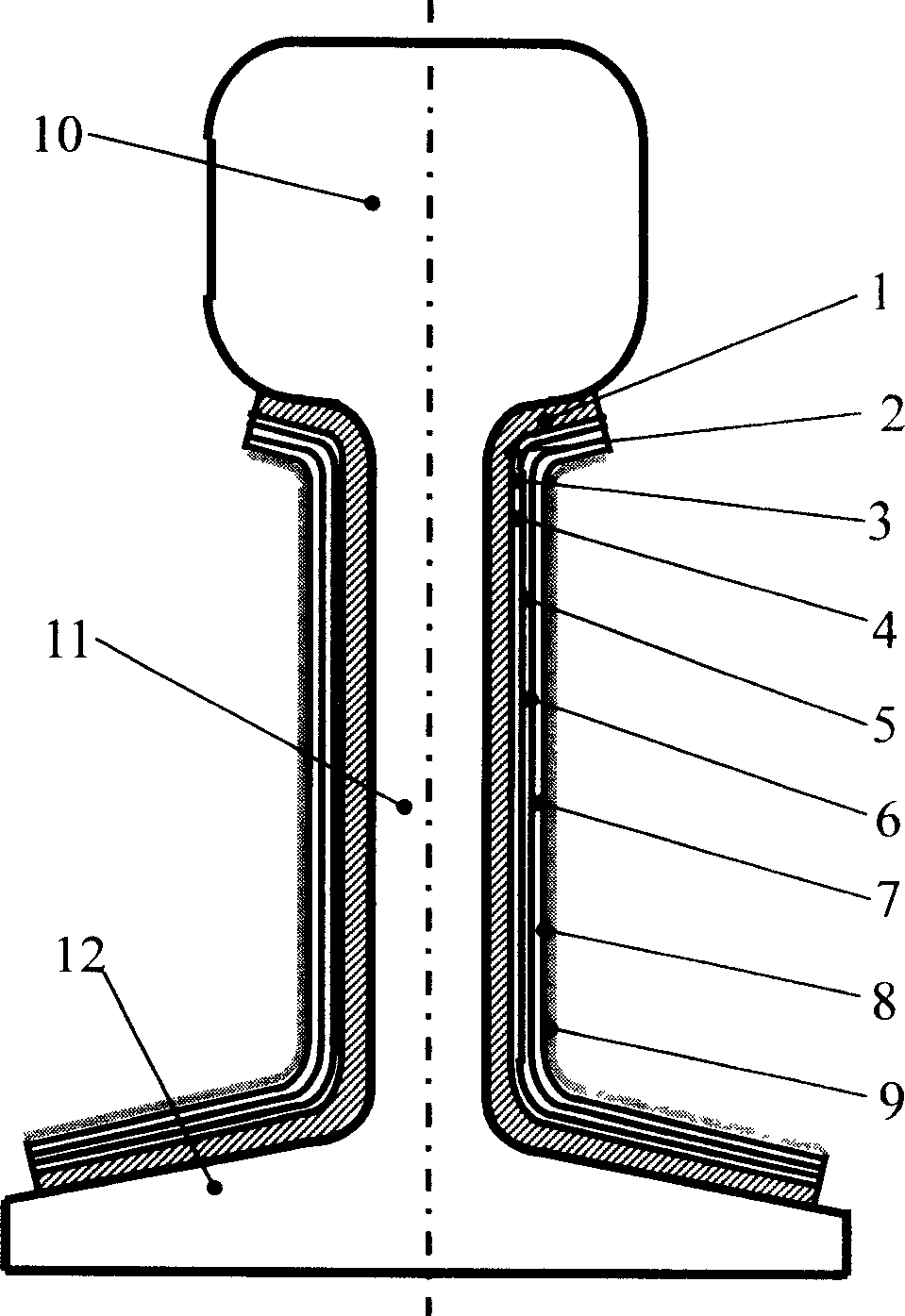

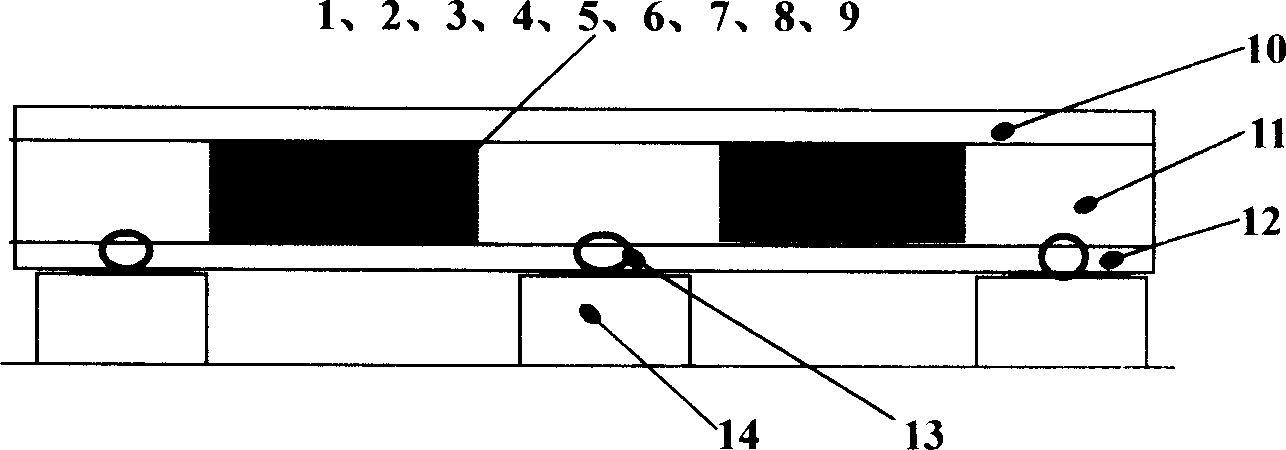

[0011] Such as figure 1 As shown, the present invention is layered in sequence, and the structure from the inside to the outside is: high elastic energy consumption material layer 1, first mass layer 2, first damping layer 3, first constraining layer 4, second damping layer 5, second The constrained layer 6, the third damping layer 7, the third constrained layer 8 and the protective layer 9. Among them, the high elastic energy consumption material layer 1 constitutes the distributed elastic elements of the dynamic vibration absorber. The first mass layer 2, the first damping layer 3, the first constraining layer 4, the second damping layer 5, the second constraining layer 6, the third The damping layer 7, the third constraining layer 8 and the protective layer 9 together constitute the distributed mass of the dynamic vibration absorber. The distributed elastic element and the distributed mass form a set of distributed parameter dynamic vibration absorbers, which can absorb the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com