Rare-earth permanent magnet material and preparation method thereof

A technology of rare earth permanent magnets and rare earth elements, which is applied in the fields of magnetic materials, inductor/transformer/magnet manufacturing, magnetic objects, etc., and can solve the problems of low maximum working temperature and low coercive force of rare earth permanent magnet materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

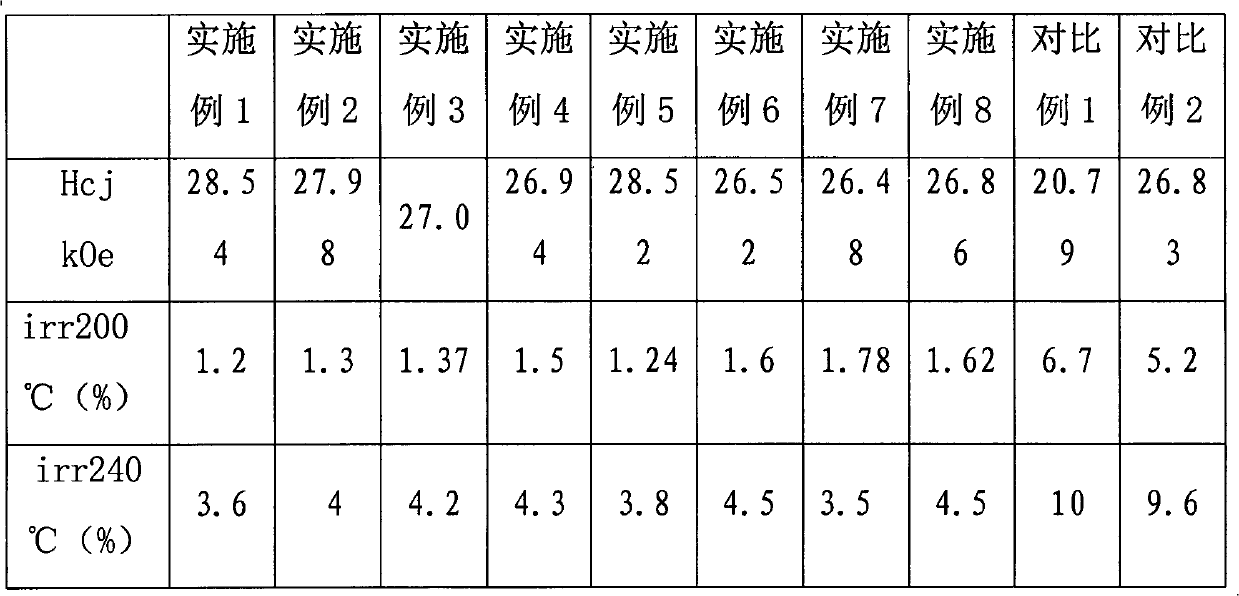

Examples

preparation example Construction

[0024] The concrete steps of the preparation method of the rare earth permanent magnet material provided by the invention are as follows:

[0025] The components of the rare earth permanent magnet material are weighed, mixed, melted, and then cast into ingots of rare earth permanent magnet materials by casting technology, or solidified thin slices of rare earth permanent magnet materials are made by quick-setting sheet technology, wherein the rare earth permanent magnet The composition of the material is: R a-x-y Ho x Dy y Fe 1-a-b-c-d co d m c B b , where x, y, a, b, c, d are the weight percentages of each element, 28%≤a≤34%, 0.95%≤b≤1.3%, 0≤c≤1.5%, 1%≤d≤10% , 15%≤x≤20%, 3%≤y≤8%, R is a rare earth element, R is selected from one or more of Nd, Pr, La, Ce, Gd, Tb, M is selected from Al, Cu , Ti, V, Cr, Zr, Hf, Mn, Nb, Sn, Mo, Ga, Si in one or more elements.

[0026] In preferred cases, 30%≤a≤33%, 0.97%≤b≤1.2%, 0.1%≤c≤1.3%. 1.5%≤d≤9%, 17%≤x≤19%, 4.1%≤y≤7.7%, R is one...

Embodiment 1

[0040] This embodiment is used to illustrate the rare earth permanent magnet material provided by the present invention and its preparation method.

[0041] 1) Based on the total weight of rare earth permanent magnet materials, weigh Pr0.46%, Nd2.02%, Dy2.8%, Tb0.2%, Ho17.91%, B1%, Fe73.11%, Co1.65 %, Al0.2%, Cu0.15%, Zr0.15%, and Ga0.1% are put into the model VI-200SC belt throwing furnace produced by Aifake Zhongbei Company to make quick-setting thin slices of rare earth permanent magnet materials , wherein, the surface linear velocity of the copper roller in the strip furnace is 1.5 m / s, and the thickness of the quick-setting sheet of rare earth permanent magnet material is 0.3 mm;

[0042] 2) The quick-setting flakes prepared in step 1 are crushed by a hydrogen crushing furnace, and then the rare earth permanent magnet material powder with an average particle diameter of 3.5 microns is made through jet milling, and the polyepoxide that accounts for 3% of the rare earth per...

Embodiment 2

[0052] This embodiment is used to illustrate the rare earth permanent magnet material provided by the present invention and its preparation method.

[0053] 1) Based on the total weight of rare earth magnetic materials, weigh Pr5.2%, Nd3.8%, Dy8%, Ho17%, B1%, Fe63.5%, Co1.5%, and put them into the In the VI-200SC belt throwing furnace, the quick-setting sheet of rare earth permanent magnet material is produced, wherein the surface speed of the copper roller in the belt throwing furnace is 1.2 m / s, and the thickness of the quick-setting sheet is 0.38 mm;

[0054] 2) The quick-setting flakes prepared in step 1 are crushed by hydrogen in a hydrogen crushing furnace, absorbed hydrogen at room temperature until saturated, dehydrogenated at 550°C, and made into hydrogen crushed powder after 6 hours, and then made by jet milling The average particle diameter is the powder of 3.8 microns, the antioxidant polyethylene oxide monofatty ester is added in the rare earth permanent magnet ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com